Preparation method of Cu2ZnSnS4 photovoltaic film

A photovoltaic thin film and thin film technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, ion implantation plating, etc., can solve the problems of difficult to obtain practical application, poor uniformity over large areas, poor reproducibility, etc. The effect of large-scale promotion, improved phase crystallization quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

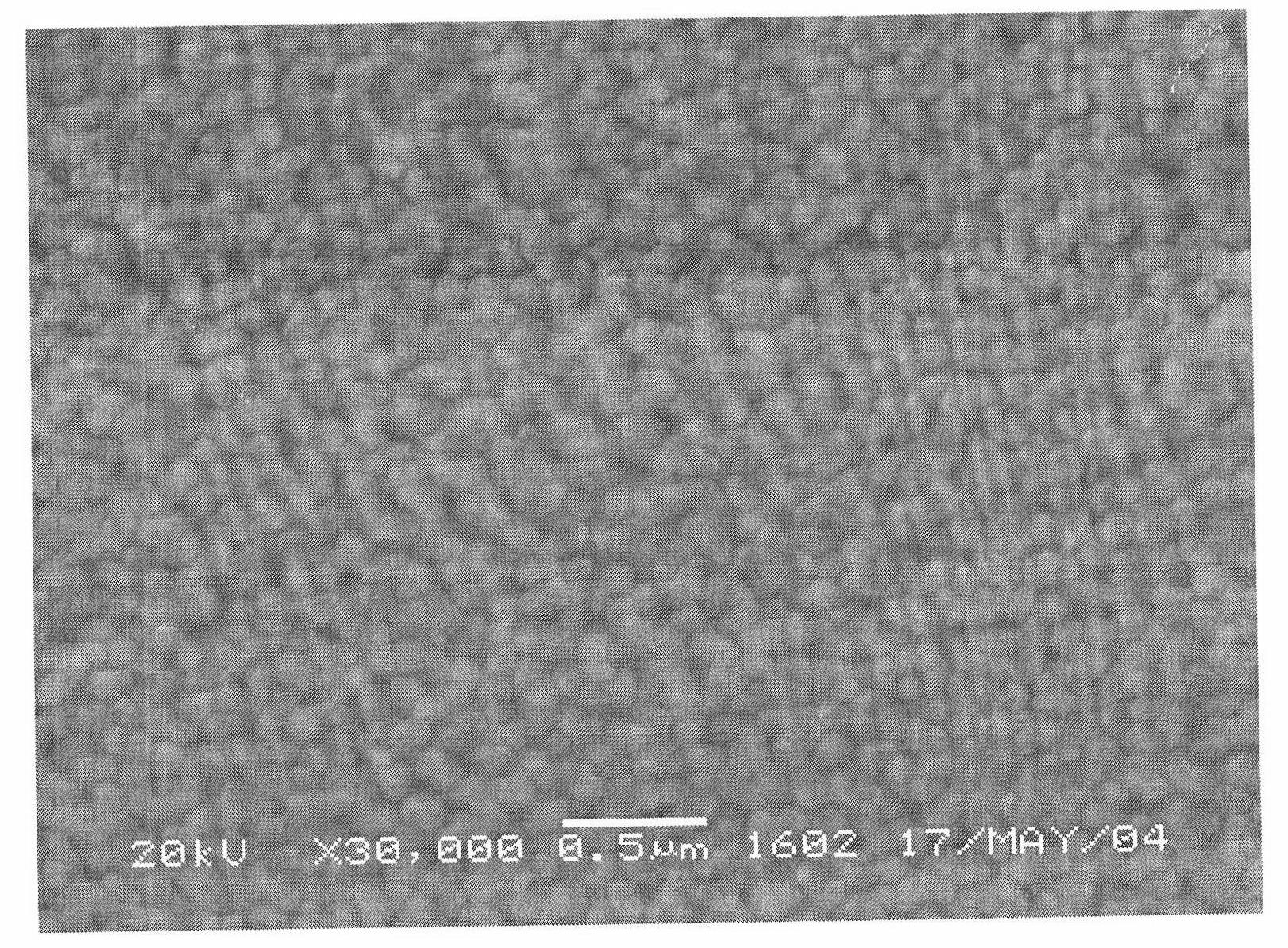

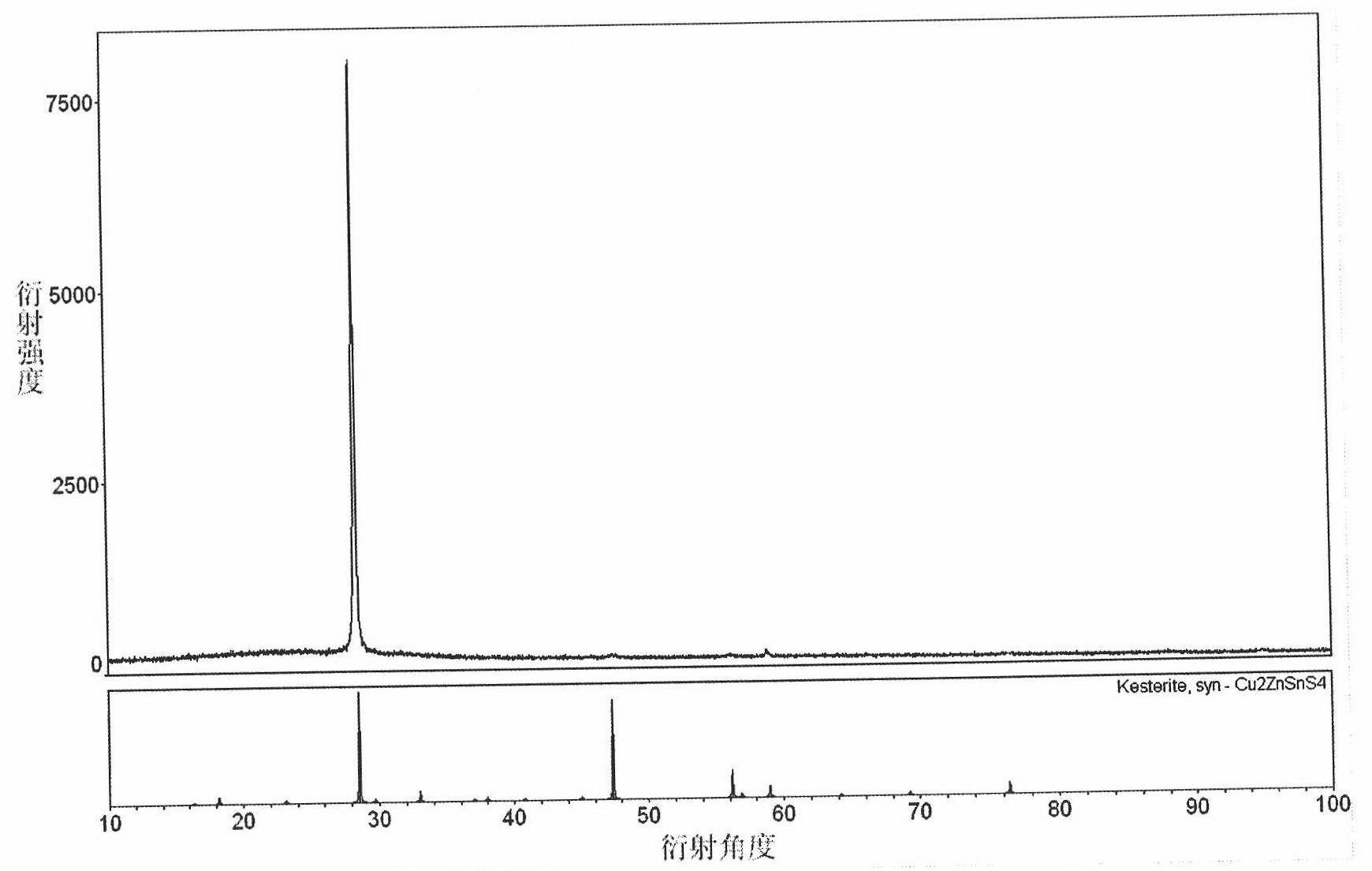

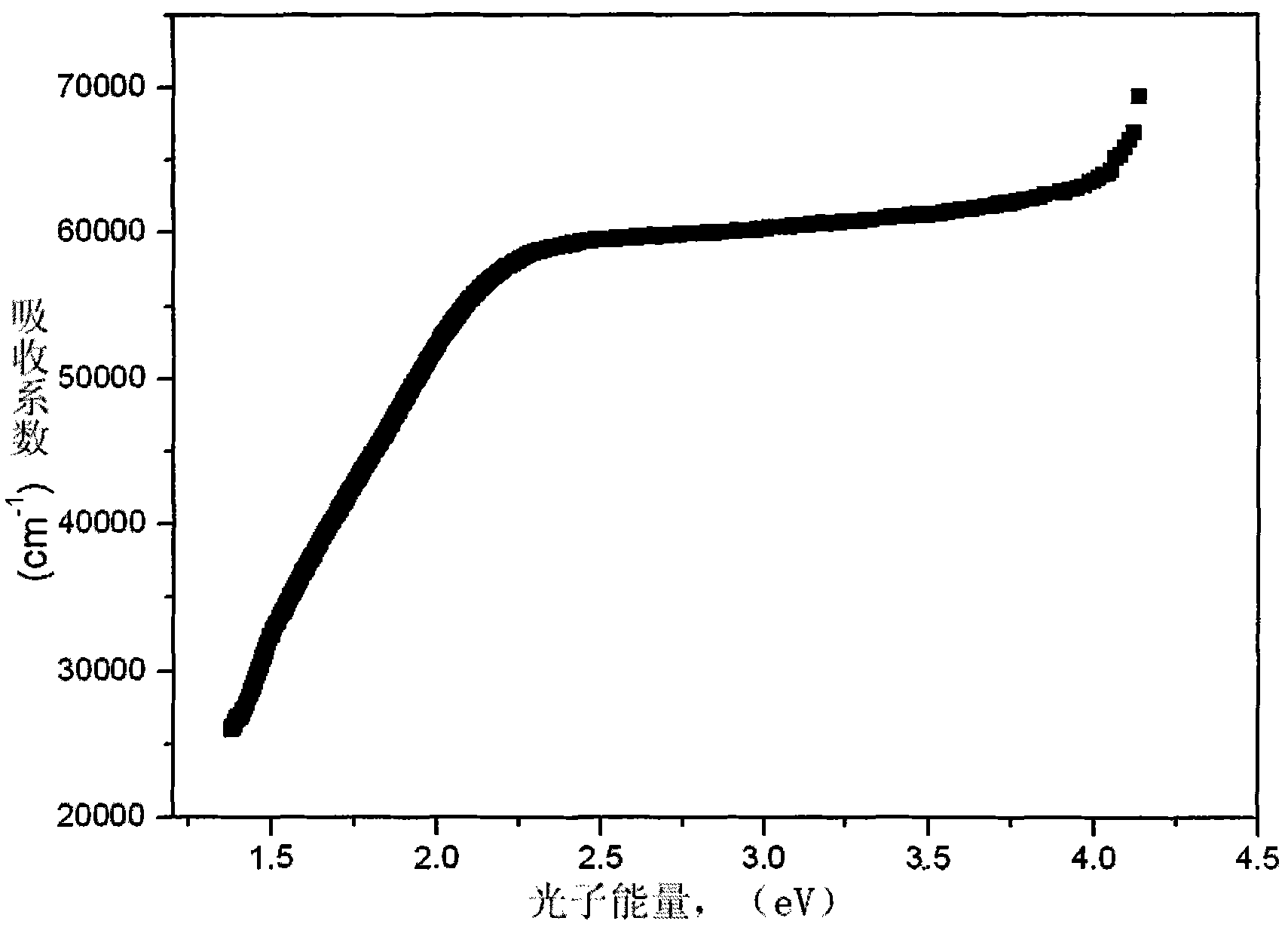

[0017] The Cu-Zn-Sn alloy target with an atomic ratio of Cu:Zn:Sn=1:0.2:1.7 is used as the cathode target, and the DC sputtering method is adopted, and the sputtering power is 160W; the mixed gas of hydrogen sulfide and argon is used as the sputtering Sputtering gas, the volume fraction of hydrogen sulfide in the mixed gas is 5%; the sputtering pressure is 0.08Pa, the distance between the target and the substrate is 8cm, the substrate temperature is 350°C, and the speed is rotated at 100 rpm. thin film deposition. Obtain Cu with a thickness of 1.2 μm 2 ZnSnS 4 Photovoltaic thin film, its conductivity type is p-type, and its bandgap width is 1.51eV.

Embodiment 2

[0019] The Cu-Zn-Sn alloy target with an atomic ratio of Cu:Zn:Sn=1:0.5:0.5 is used as the cathode target, and the DC sputtering method is adopted, and the sputtering power is 80W; the mixed gas of hydrogen sulfide and argon is used as the sputtering Sputtering gas, the volume fraction of hydrogen sulfide in the mixed gas is 80%, the sputtering pressure is 1Pa, the distance between the target and the substrate is 11cm, the substrate temperature is 500°C, and rotates at a rate of 4 revolutions per minute to perform thin film deposition. Obtain Cu with a thickness of 1 μm 2 ZnSnS 4 Photovoltaic thin film, its photoelectricity and other performance parameters are as follows:

[0020] thickness

Embodiment 3

[0022] The Cu-Zn-Sn alloy target with an atomic ratio of Cu:Zn:Sn=1:1.7:0.3 is used as the cathode target, and the radio frequency sputtering method is adopted, and the sputtering power is 30W; the hydrogen sulfide gas is used as the sputtering gas, and the sputtering The air pressure is 5Pa, the distance between the target and the substrate is 6cm, the substrate temperature is 650°C, and the thin film is deposited without rotation. Obtain Cu with a thickness of 0.5 μm 2 ZnSnS 4 Photovoltaic thin film, its conductivity type is p-type, and its bandgap width is 1.48eV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com