Method for recycling waste silicon powder in production process of trichlorosilane

A production process, trichlorosilane technology, applied in separation methods, chemical instruments and methods, silicon, etc., can solve the problems affecting the health of workers in the factory environment, waste silicon powder discharge and stacking are easy to catch fire, and there is no water spray in the leaching tower. and other problems, to achieve the effect of promoting rapid development, remarkable energy saving effect, and eliminating safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

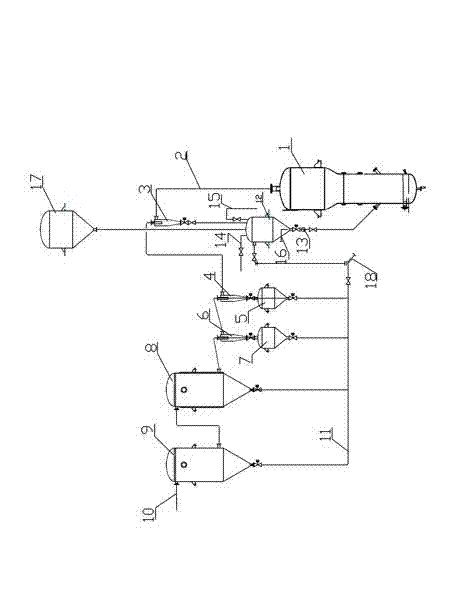

[0022] The mixed gas generated in the synthesis furnace enters the high-efficiency cyclone separator 3 through the mixed gas outlet pipe 2 of the synthesis furnace. The outlet pressure of the high-efficiency cyclone separator 3 is 30-35 Kpa, and the separated silicon powder particles enter the silicon powder recovery tank 12. The gas from the high-efficiency cyclone separator 3 passes through the first-stage cyclone separator 4 and the second-stage cyclone separator 6 in turn. The outlet pressure of the first-stage cyclone separator is 28~33Kpa, and the outlet pressure of the second-stage cyclone separator is 26~30Kpa. . The separated silicon powder particles enter the primary slag storage tank 5 and the secondary slag storage tank 7 respectively, and then enter the silicon powder recovery tank 12 through the slag blowing pipeline 11; the mixed gas from the secondary cyclone separator 6 passes through the primary The bag filter 8 and the secondary bag filter 9, the outlet pres...

Embodiment 2

[0033] The mixed gas generated in the synthesis furnace enters the high-efficiency cyclone separator 3 through the mixed gas outlet pipe 2 of the synthesis furnace. The outlet pressure of the high-efficiency cyclone separator 3 is 30Kpa, and the separated silicon powder particles enter the silicon powder recovery tank 12. The gas coming out from the high-efficiency cyclone separator 3 passes through the primary cyclone separator 4 and the secondary cyclone separator 6 successively. The outlet pressure of the primary cyclone separator is 28Kpa, and the outlet pressure of the secondary cyclone separator is 26Kpa. The separated silicon powder particles enter the primary slag storage tank 5 and the secondary slag storage tank 7 respectively, and then enter the silicon powder recovery tank 12 through the slag blowing pipeline 11; the mixed gas from the secondary cyclone separator 6 passes through the primary Bag filter 8 and secondary bag filter 9, the outlet pressure of the first b...

Embodiment 3

[0036]The mixed gas generated in the synthesis furnace enters the high-efficiency cyclone separator 3 through the mixed gas outlet pipe 2 of the synthesis furnace. The outlet pressure of the high-efficiency cyclone separator 3 is 35 Kpa, and the separated silicon powder particles enter the silicon powder recovery tank 12. The gas from the high-efficiency cyclone separator 3 passes through the first-stage cyclone separator 4 and the second-stage cyclone separator 6 successively. The outlet pressure of the first-stage cyclone separator is 33Kpa, and the outlet pressure of the second-stage cyclone separator is 30Kpa. The separated silicon powder particles enter the primary slag storage tank 5 and the secondary slag storage tank 7 respectively, and then enter the silicon powder recovery tank 12 through the slag blowing pipeline 11; the mixed gas from the secondary cyclone separator 6 passes through the primary Bag filter 8 and secondary bag filter 9, the outlet pressure of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com