Hollow core-shell nanometer mesoporous medicament carrying system with magnetism and luminescent performance, preparation method and application thereof

A technology with luminescent properties and magnetic properties, which can be used in medical preparations of non-active ingredients, preparations for in vivo experiments, drug delivery, etc. It can solve the problems of disintegration and release, poor thermal stability and chemical stability, and achieve easy operation , good water solubility and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Preparation of β-FeOOH nanoparticles

[0039] Using hydrothermal method, 4mmol FeCl 3 ·6H 2 O and 1.0 g of polyvinylpyrrolidone (PVP, K-30) were dissolved in 70 mL of deionized water, transferred to a 100 mL stainless steel hydrothermal kettle with a polytetrafluoroethylene liner, and placed in an oven at 100 °C for 10 h. Take it out, cool to room temperature, centrifuge, wash with water three times, and vacuum dry at room temperature for 36 hours to obtain spindle-shaped β-FeOOH nanoparticles.

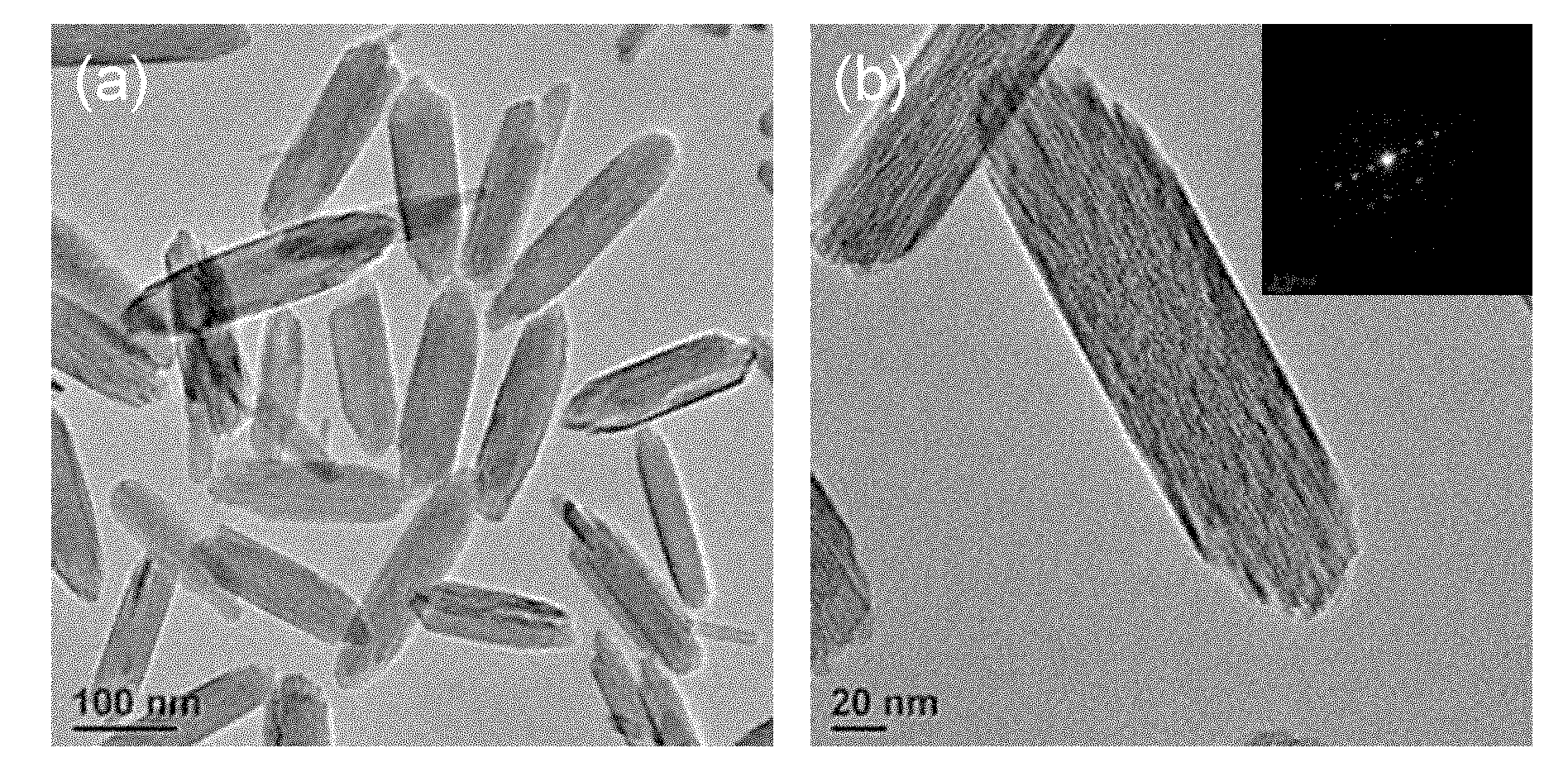

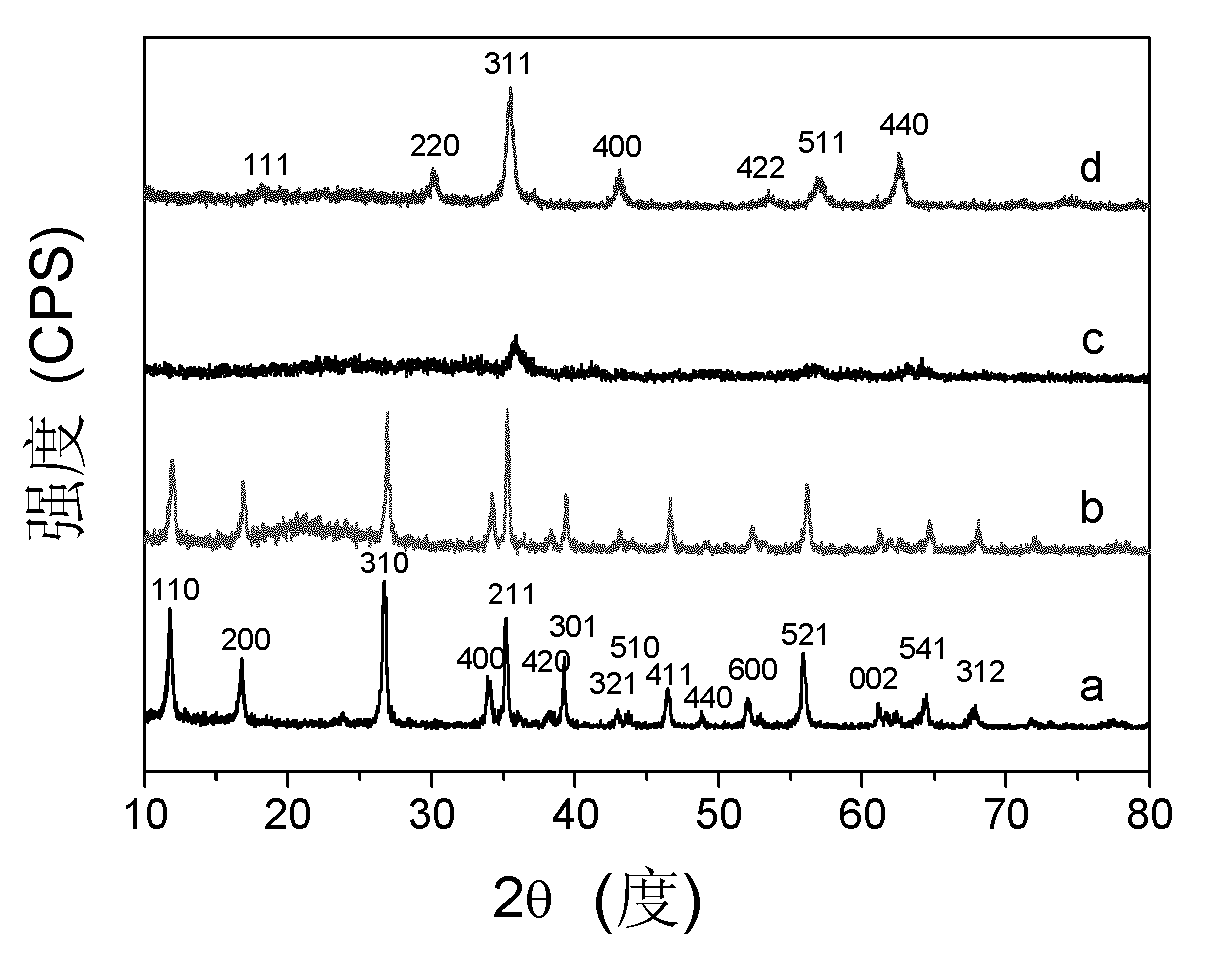

[0040] The TEM picture of embodiment 1 gained material is as figure 1 As shown, it can be seen from the figure that the average length of nanoparticles is 180nm; the average diameter is 53nm; figure 1 The illustration in (b) is figure 1 Selected-area electron diffraction pattern of a β-FeOOH nanoparticle in (b), showing that the nanoparticle has a single-crystal structure. XRD spectrum as image 3 As shown in (a), it shows that the β-FeOOH nanoparticles obta...

Embodiment 2

[0041] Example 2: The surface of β-FeOOH is coated with SiO containing alkyl chains 2 Preparation of Nanocomposite Core-Shell Materials

[0042] Using the sol-gel method, uniformly disperse 100 mg of β-FeOOH nanoparticles obtained in Example 1 in a mixed solution of 50 mL of water and 250 mL of isopropanol, add 7.5 mL of ammonia water, and then add dropwise a total volume of 0.4 mL of orthosilicon Tetraethyl orthosilicate and octadecyltrimethoxysilane, continue to stir for 3h after adding, then centrifuge, wash the solid with ethanol 3 times, and finally vacuum dry at room temperature for 24h; Tetraethyl orthosilicate and octadecyl The amount of substance ratio of trimethoxysilane was 4.7.

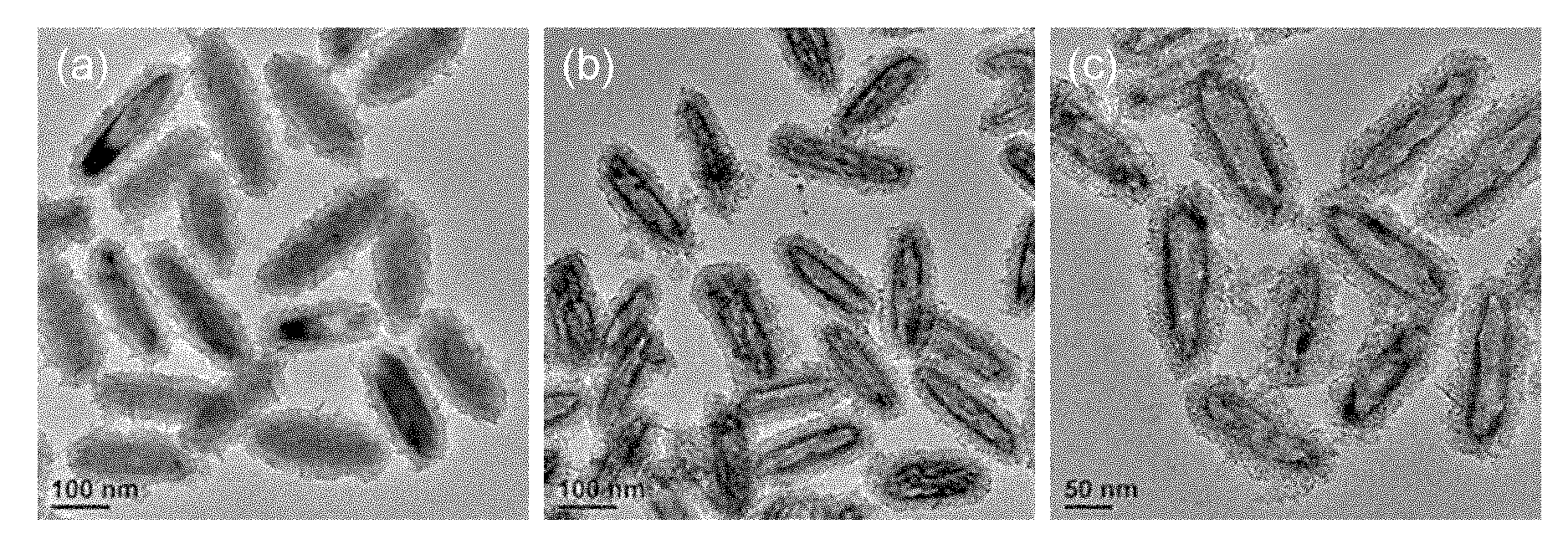

[0043] The TEM picture of embodiment 2 gained material is as figure 2 As shown in (a), it shows that the surface of β-FeOOH obtained in Example 2 wraps SiO containing alkyl chains 2 The composite core-shell nanoparticles have a core-shell structure, and the average thickness of the she...

Embodiment 3

[0044] Example 3: α-Fe 2 o 3 @mSiO 2 Preparation of Hollow Nanocomposite Capsules

[0045] The β-FeOOH surface of the obtained β-FeOOH of Example 2 is wrapped with SiO containing alkyl chains 2 The composite core-shell nanoparticles were heat-treated in air at 550 °C for 6 hours to remove the pore-forming agent and transform the inner core from β-FeOOH to α-Fe 2 o 3 , so that a cavity is formed in the inner core to form a hollow nanocapsule structure; the heating rate of the heat treatment is 1° C. / min.

[0046] The TEM picture of embodiment 3 gained material is as figure 2 Shown in (b), show that embodiment 3 gained α-Fe 2 o 3 @mSiO 2 The nanocomposite capsule has a cavity structure, and the inner α-Fe 2 o 3 It has a hollow nanocapsule structure, the outer wall of which is tightly attached to the inner wall of mesoporous silica. XRD spectrum as image 3 Shown in (c), show that embodiment 3 gained α-Fe 2 o 3 @mSiO 2 The structure of β-FeOOH no longer exists in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com