Preparation method of cathode material of lithium ion battery coated with metal oxides on surface

A lithium-ion battery, surface coating technology, applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of high price, poor safety, and unguaranteed product consistency, and achieve simple preparation methods, cycle performance and safety The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 10g MgCl 2 ·6H 2 O was dissolved in a mixture of 200ml 50°C water and acetone (volume ratio 2:1); add 5M ammonia water and stir to adjust the pH value to 3.2 to form a sol-like substance; add 100g LiCoO 2 Powder and stir evenly, react for 3 hours, stand still, remove the supernatant, and dry the obtained sediment at 70°C; bake the dried sediment at 850°C for 4 hours, and obtain the MgO coating amount of 2% cathode material LiCoO 2 .

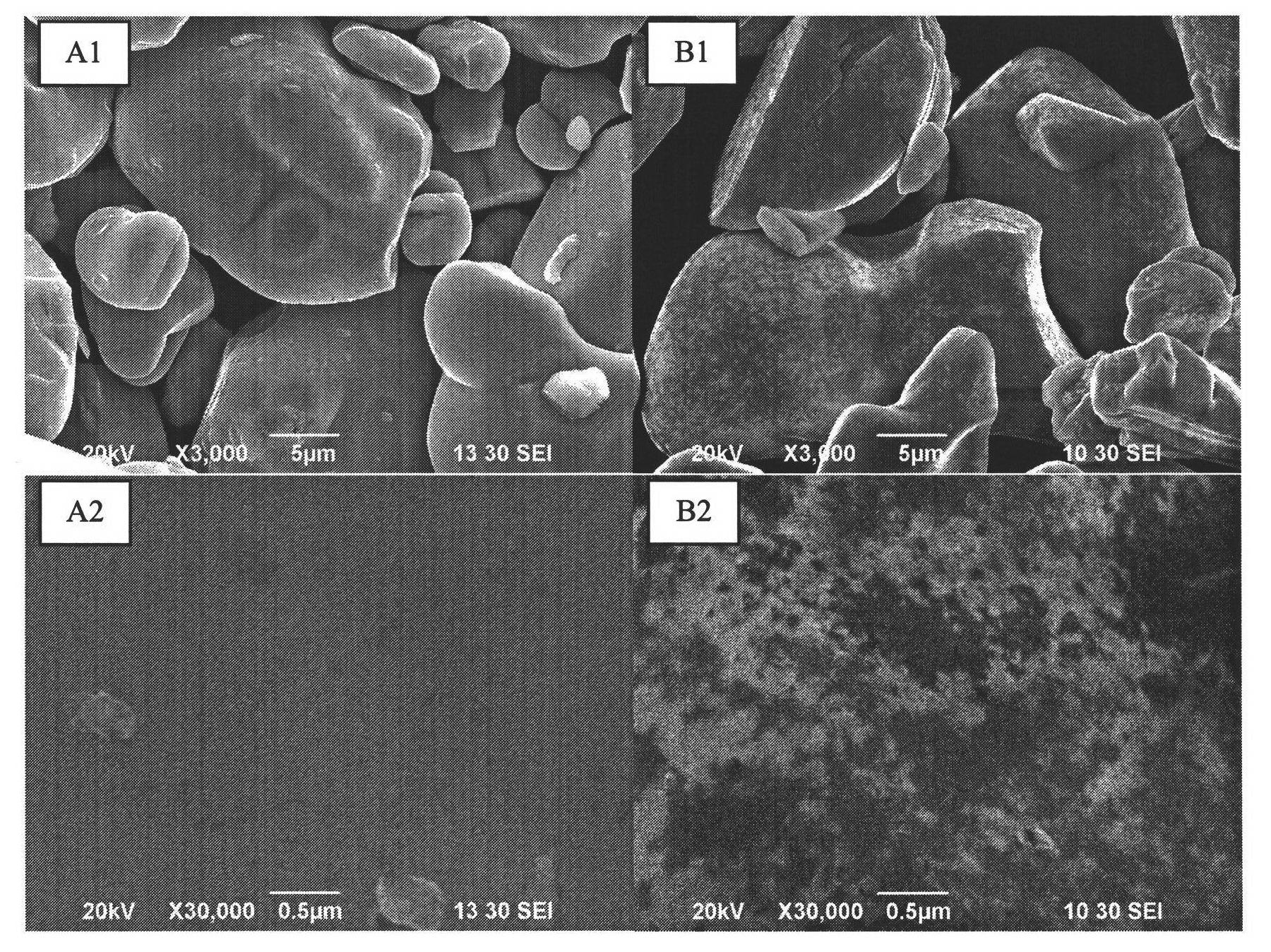

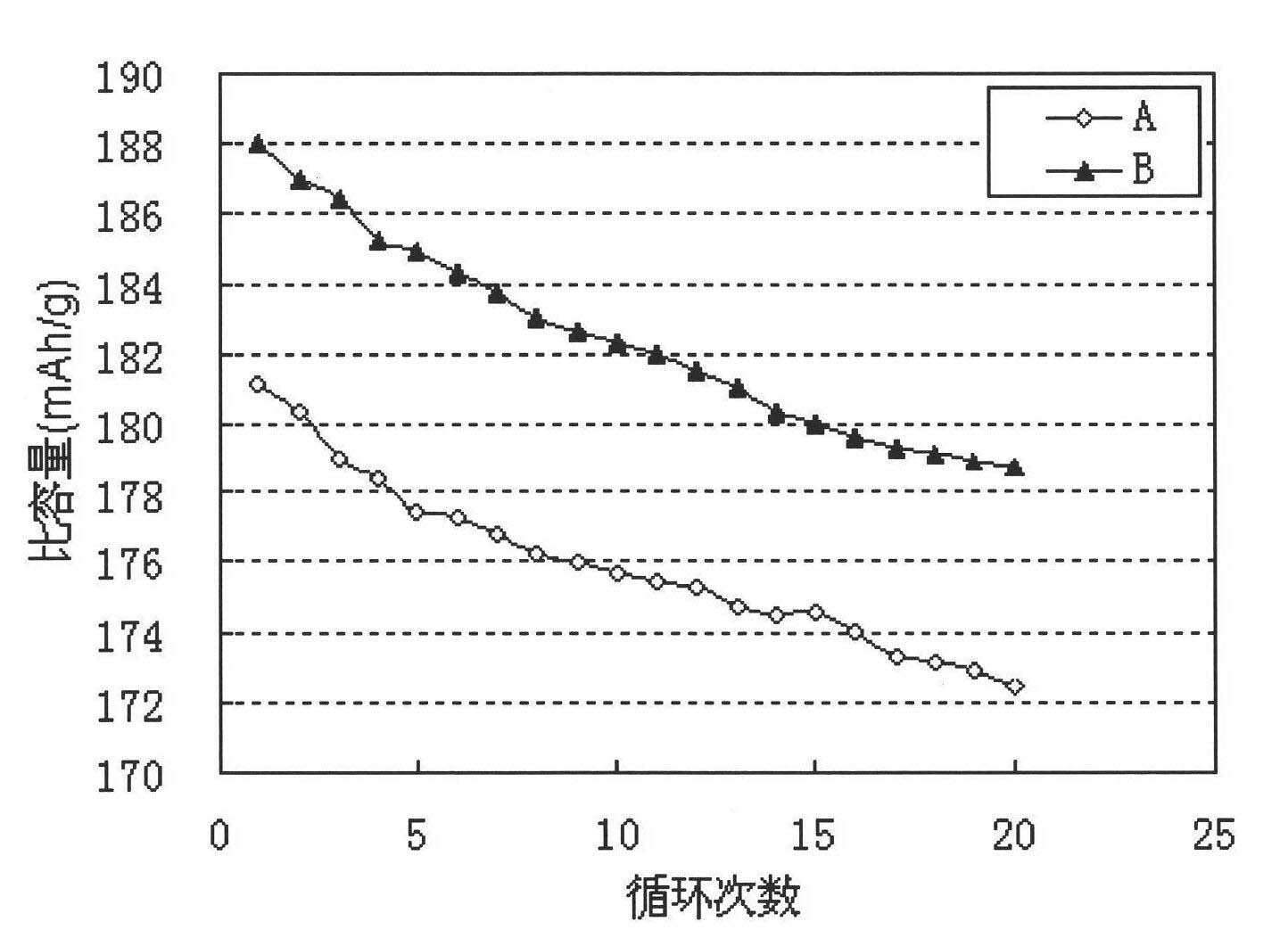

[0040] The surface-coated MgO positive electrode material LiCoO prepared according to the aforementioned method 2 It is uniformly mixed with conductive carbon and polyvinylidene fluoride (PVDF) to prepare a positive electrode slurry, and coated on the positive electrode current collector to form a positive electrode sheet, and a lithium sheet is used as a negative electrode sheet to form a button battery in a glove box for electrochemical test. figure 1 for LiCoO 2 SEM images before and after the surface is coated with MgO. It ...

Embodiment 2

[0042] Weigh 22.1g Al(NO 3 ) 3 9H 2 Dissolve O in 500ml of water at 90°C to form a solution; add 5M ammonia water to adjust the pH value to 4.5 to form a sol-like substance; add 100g LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Powder and stir evenly, react for 6 hours, stand still, remove the supernatant, and dry the obtained sediment at 90°C; bake the dried sediment at 650°C for 3 hours to obtain Al 2 o 3 The positive electrode material LiNi with coating amount of 3% 1 / 3 co 1 / 3 mn 1 / 3 o 2 .

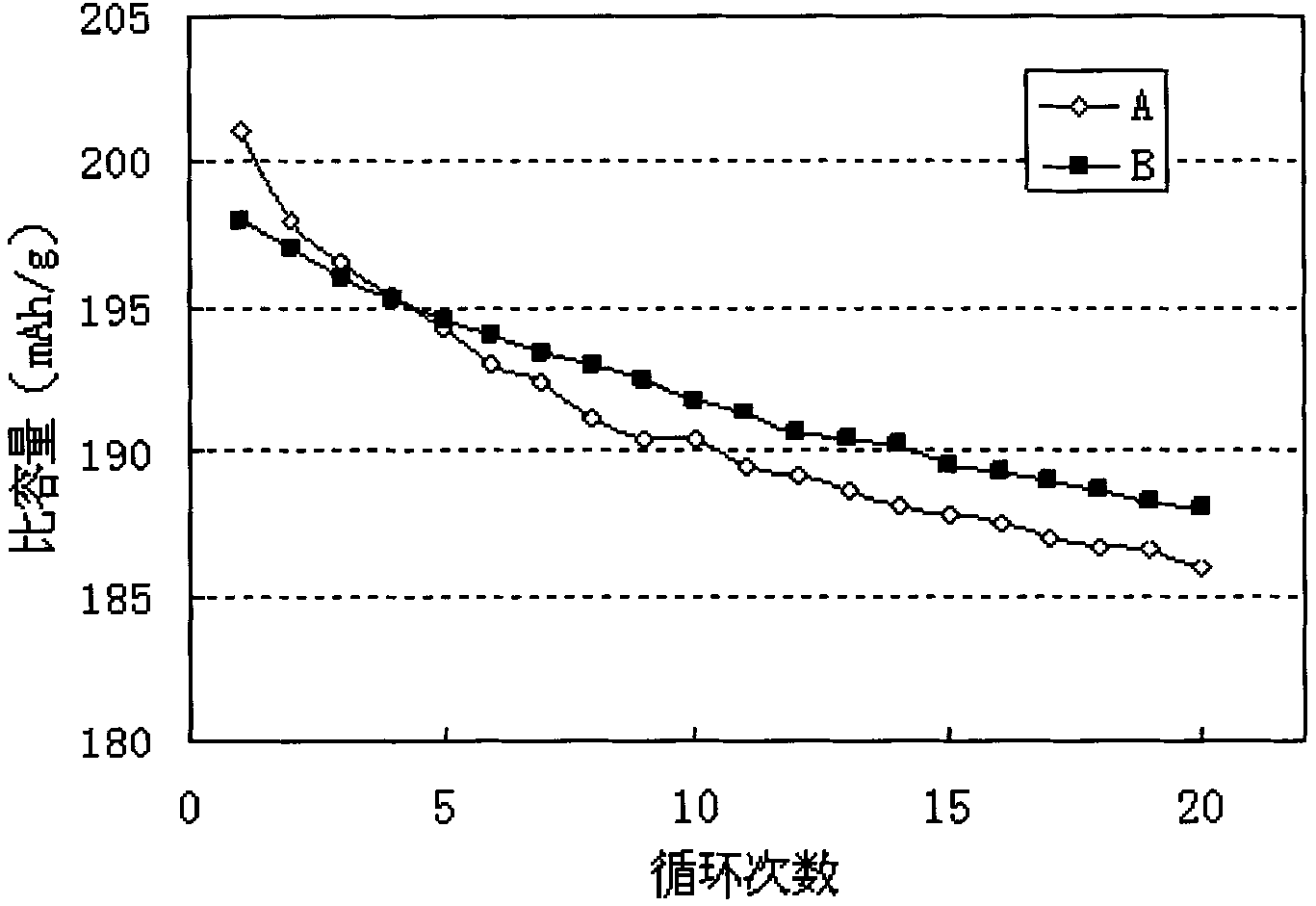

[0043] The surface coating Al obtained by the aforementioned method 2 o 3 Cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 It is uniformly mixed with conductive carbon and polyvinylidene fluoride (PVDF) to prepare a positive electrode slurry, and coated on the positive electrode current collector to form a positive electrode sheet, and a lithium sheet is used as a negative electrode sheet to form a button battery in a glove box for electrochemical test. image 3 for LiNi 1 / 3 co 1 / 3 mn 1 / 3...

Embodiment 3

[0045] Weigh 9.5g TiOSO 4 ·8H 2 Dissolve O in 300ml ethanol at 40°C to form a solution; add 5M ammonia water to adjust the pH value to 4 to form a sol-like substance; add 100g LiNi 0.8 co 0.2 o 2 Powder and stir evenly, react for 3 hours, stand still, remove the supernatant, and dry the obtained sediment at 80°C; bake the dried sediment at 500°C for 3 hours to obtain TiO 2 Cathode material LiNi with coating amount of 2.5% 0.8 co 0.2 o 2 .

[0046] The surface-coated TiO prepared according to the aforementioned method 2 Cathode material LiNi 0.8 co 0.2 o 2 It is uniformly mixed with conductive carbon and polyvinylidene fluoride (PVDF) to prepare a positive electrode slurry, and coated on the positive electrode current collector to form a positive electrode sheet, and a lithium sheet is used as a negative electrode sheet to form a button battery in a glove box for electrochemical test. Figure 4 LiNi shown 0.8 co 0.2 o 2 Surface coated TiO 2 Before and after, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com