Method for extracting and separating kaempferol from impatiens balsamina

A separation method, the technology of kaempferol, applied in the direction of organic chemistry, etc., can solve the problems of limited amount of kaempferol, complex process, expensive dextran gel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0035] Experimental Example 1: Purity Check of Kaempferol

[0036] Check the purity by HPLC. Instrument: Waters 600 high performance liquid chromatography. Column: YWG-C 18 Chromatography column, 250mm×4.6mm, 5μm. Mobile phase: methanol-0.1% phosphoric acid aqueous solution (50~70:50~30); flow rate: 0.8~1.2mL / min; column temperature: room temperature; detection wavelength: 367nm; injection volume: 10μl; retention time (RT): Kaempferol: 5-30min; chromatogram recording time: 60min. The area normalization method measures the purity, and the purity of kaempferol is 98.8%.

experiment example 2

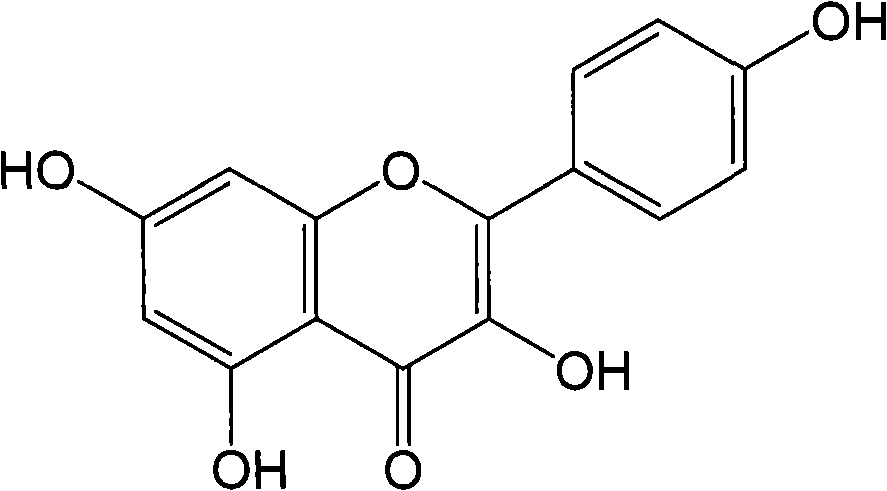

[0037] Experimental Example 2: Determination of the structure of kaempferol

[0038] Melting point was measured by X-4 digital display microscopic melting point tester; ultraviolet (UV) spectrum was measured by Japan Shimadzu UV-260 UV-visible spectrophotometer; infrared (IR) spectrum was measured by Perkin-Elmer 983G instrument, KBr tablet ; H NMR and C NMR spectra ( 1 HNMR and 13 CNMR) is measured with MERCURY-400 nuclear magnetic resonance instrument; Mass spectrometry (MS) is measured with Finnigan-LCQ DECA type mass spectrometry.

[0039]The pure kaempferol obtained by the above-mentioned purification method is yellow granular crystal with a melting point of 276-278°C. UVλmax (nm): 226, 267, 349. IRυmax(KBr, cm -1 ): 3324 (OH), 1662 (C=O). MS (m / z): 309 (M+Na). 1 H NMR (δ, DMSO-d 6 ): 12.47 (5-OH), 10.85 (7-OH), 10.12 (3-OH), 9.43 (4'-OH), 8.03 (2H, d, J=9.0 Hz, C 2′ -H,C 6′ -H), 6.91 (2H, d, J=9.0Hz, C 3′ -H,C 5′ -H), 6.43 (1H, d, J=1.8Hz, C 8 -H), 6.18 (1H,...

experiment example 3

[0042] Experimental Example 3 Experiment of macroporous adsorption resin for enriching crude kaempferol

[0043] Take 2.5kg of dried balsam flower petals, add 75L of ethanol with a concentration of 80%, heat and reflux for extraction for 1 hour, filter, extract the medicinal residues successively 3 times by the same method, combine the extracts, and discard the medicinal residues; the extracts are recovered Ethanol to obtain a thick paste that is total extract 0.68kg.

[0044] Take 0.68kg of the above-mentioned total extract, add 15L of water to dilute, use a D101 type macroporous adsorption resin column, the resin amount is 20L (volume in water), the diameter-to-height ratio is 1:6, and the adsorption flow rate is 3BV / h; first wash out 9BV with water , the flow rate is 3BV / h, then 9BV is eluted with 30% ethanol, the flow rate is 3BV / h; finally, the 4BV is eluted with 50% ethanol, the flow rate is 2BV / h, this part of the eluate is collected, and the solvent is recovered to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com