Water-soluble coenzyme Q10 combination and preparation method thereof

A composition and water-soluble technology, which is applied in the field of medicine, can solve the problems of insufficient content of coenzyme Q10 active substances, low stability of inclusion compound suspension or precipitation, etc., and achieve the effect of low cost, easy acquisition and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepared by dissolving coenzyme Q10 in an organic solvent and then mixing it with an emulsifier:

[0036] Take 10g of coenzyme Q10 and 20g of polyoxyethylene-40-stearate, dissolve in 100ml of absolute ethanol, stir to form a clear and transparent solution as a spare solution; take 1000ml of 50°C hot water, add 65g of water-soluble starch and 5g of CMC, While stirring and dissolving to clarify the solution, add the reserve solution at a dropping rate of 0.35 ml / s, cut it with a shear disperser at a speed of 3000 rpm for 60 minutes, take it out, and spray it under the drying parameters of 170°C for air inlet and 90°C for air outlet Dry, collect the spray powder and sieve to obtain the finished product.

[0037] The following is the performance test of the obtained water-soluble coenzyme Q10 composition: the method for determining the content of the water-soluble coenzyme Q10 composition mainly adopts high-performance liquid chromatography. About 1mg / ml), filter, take the...

Embodiment 2

[0055] Prepared by direct heating and melting of coenzyme Q10 and emulsifier:

[0056] Take 10g of coenzyme Q10, 80g of pure gum, 30g of sucrose fatty acid ester and 0.5g of vitamin E, dissolve them in 200ml of water, heat to 60°C to melt, then use a shearing disperser to cut at 2000rpm for 50min, take it out, and put it in the air Spray drying under the drying parameters of 170°C and air outlet of 90°C, collect the spray powder and sieve to obtain the finished product.

[0057] The performance testing method of the obtained water-soluble coenzyme Q10 composition is the same as that in Example 1.

[0058] 1. Stability test

[0059] The maximum absorption wavelength of coenzyme Q10 is 275±1nm, and the maximum absorption wavelength of reduced coenzyme Q10 is 291±1 nm. The detection value of the water-soluble coenzyme Q10 composition in this experiment is 4% under the chromatographic conditions (C18 column, mobile phase: methanol: absolute ethanol = 1:1, detection wavelength 29...

Embodiment 3

[0075] Prepared by dissolving coenzyme Q10 in an organic solvent and then mixing it with an emulsifier:

[0076] Take 15g of coenzyme Q10, 20g of sorbitol fatty acid ester and 20g of poloxamer, dissolve it in 150ml of ethyl acetate, stir it into a clear and transparent solution as a spare solution; take 3000ml of 40°C hot water, add 60g of lactose and 40g of gum arabic , while stirring and dissolving to clarify the solution, add the reserve liquid at a dropping rate of 0.5 ml / s, cut it with a shear disperser at a speed of 4000 rpm for 80 minutes, and take it out. Spray drying, collecting the spray powder and sieving to obtain the finished product.

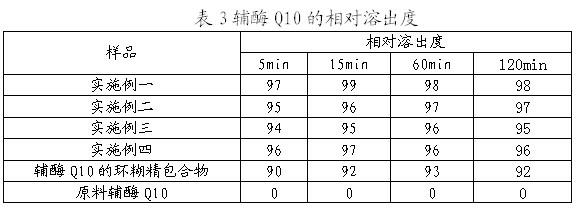

[0077] The performance test method of the obtained water-soluble coenzyme Q10 composition is the same as in Example 1, and the results are shown in Table 1, Table 2 and Table 3.

[0078] Table 1 shows that light has a greater impact on coenzyme Q10. The water-soluble coenzyme Q10 composition in Example 3 of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com