Composite bacterial agent and biological method for treating flow-back fracturing fluid to obtain oil displacement active water

A technology of composite bacterial agent and flowback liquid, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of consumption of water treatment agents, water quality impact, and difficult treatment, and shorten the hydraulic retention time , save energy consumption, improve the effect of interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the compounding of microbial bacterial agent

[0025] The bacteria growing in the formation water of the oil well were enriched and cultured, then streaked on the LB agar plate, cultured at 37°C for 16 hours, a single colony was picked, and after screening, a strain was obtained, which was identified as Rhodococcus equi and numbered BS001 ;

[0026] At the same time, commercially known bacterial strains were taken: Pseudomonas aeruginosa, T. crassa, Bacillus subtilis, Bacillus cereus, and Paecillin were numbered BS002, BP001, BS003, BC001, and BP002, respectively.

[0027] Configure seed liquid culture medium, formula is: peptone, 10g / L; Yeast powder, 5g / L; NaCl, 5g / L; Molasses, 1% (volume ratio); KH 2 PO 4 , 3g / L; K 2 HPO 4 , 1.5g / L; natural pH. Sterilize at 115°C for 15 minutes. The liquid volume is 100mL / 250mL bottle volume. Pick the above-mentioned 6 strains and single colonies from each bottle. The constant temperature shaker rotates at 150rpm a...

Embodiment 2

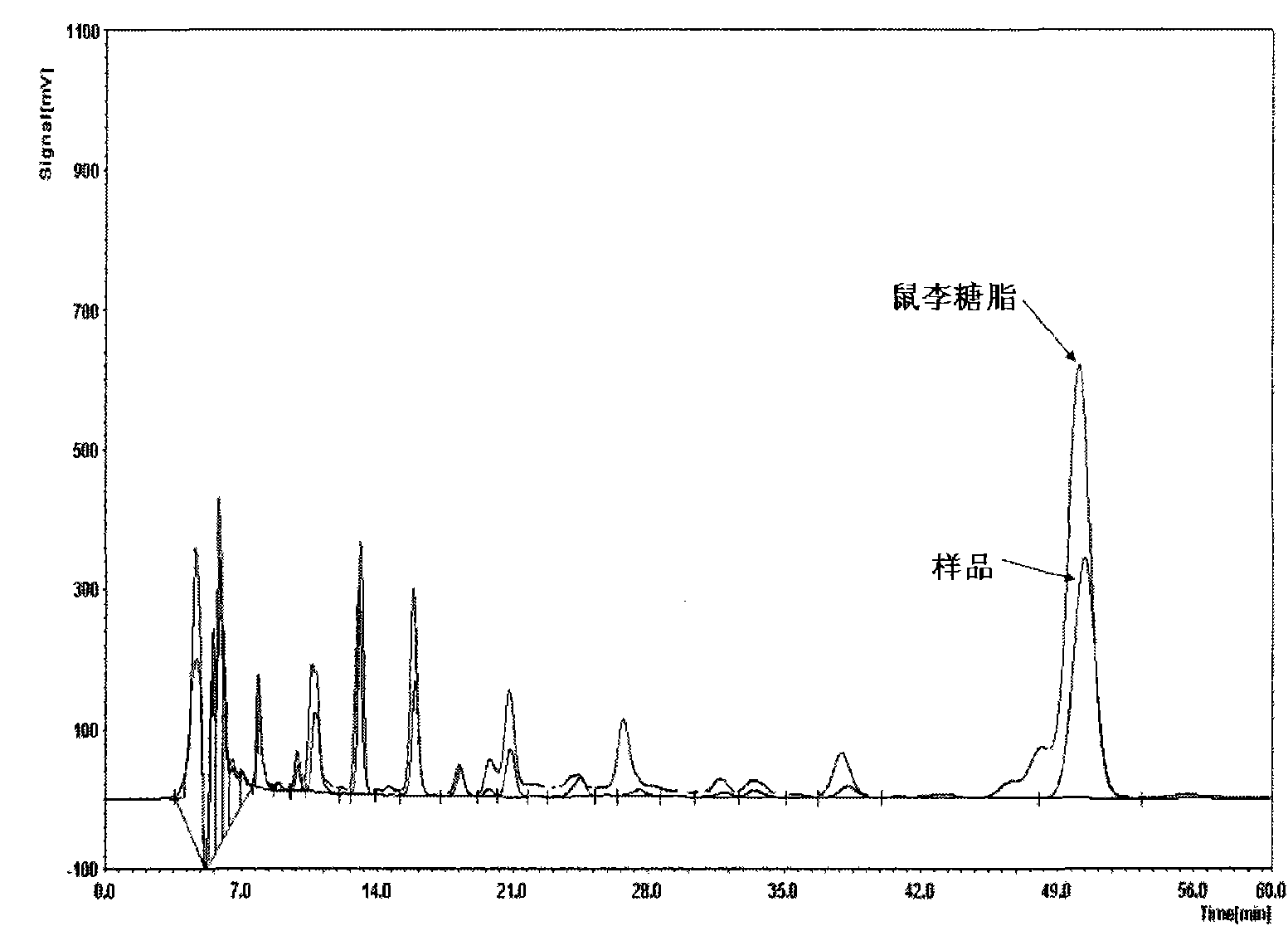

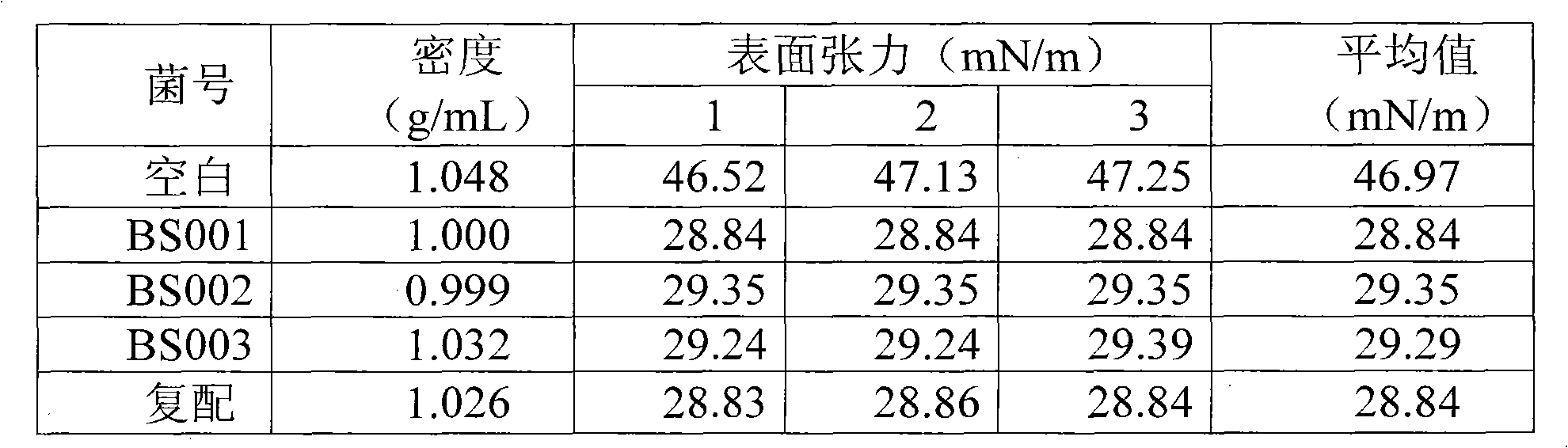

[0029] Embodiment 2: the validation of compound bacterial agent producing biosurfactant

[0030] The surface tension of the fermentation broth was measured with the JYW-200 automatic surface / interfacial tension meter of Chengde Dingsheng Testing Machine Testing Co., Ltd. at room temperature to measure the surface tension of the fermentation broth. Each measurement was repeated three times, and the average value was taken. The specific operation of the surface tension is as follows: take 30mL fermentation broth and centrifuge at 8000rpm for 10min, take the supernatant in a measuring cup, and measure the surface tension with a platinum ring.

[0031] The liquid fermentation medium is as follows (by weight ratio):

[0032] Guar Gum Broken Liquid Monosaccharide [β-mannanase, Bio-Thera Port (Dalian) Biotechnology Co., Ltd.] 5g, NH 4 NO 3 2.0g, K 2 HPO 4 ·3H 2 O 3.0g, NaH 2 PO 4 2H 2 O 10g, MgSO 4 ·7H 2 O0.2g, MnCl 2 4H 2 O 2ppm, yeast extract 0.2g, adjust pH=7.0 with Na...

Embodiment 3

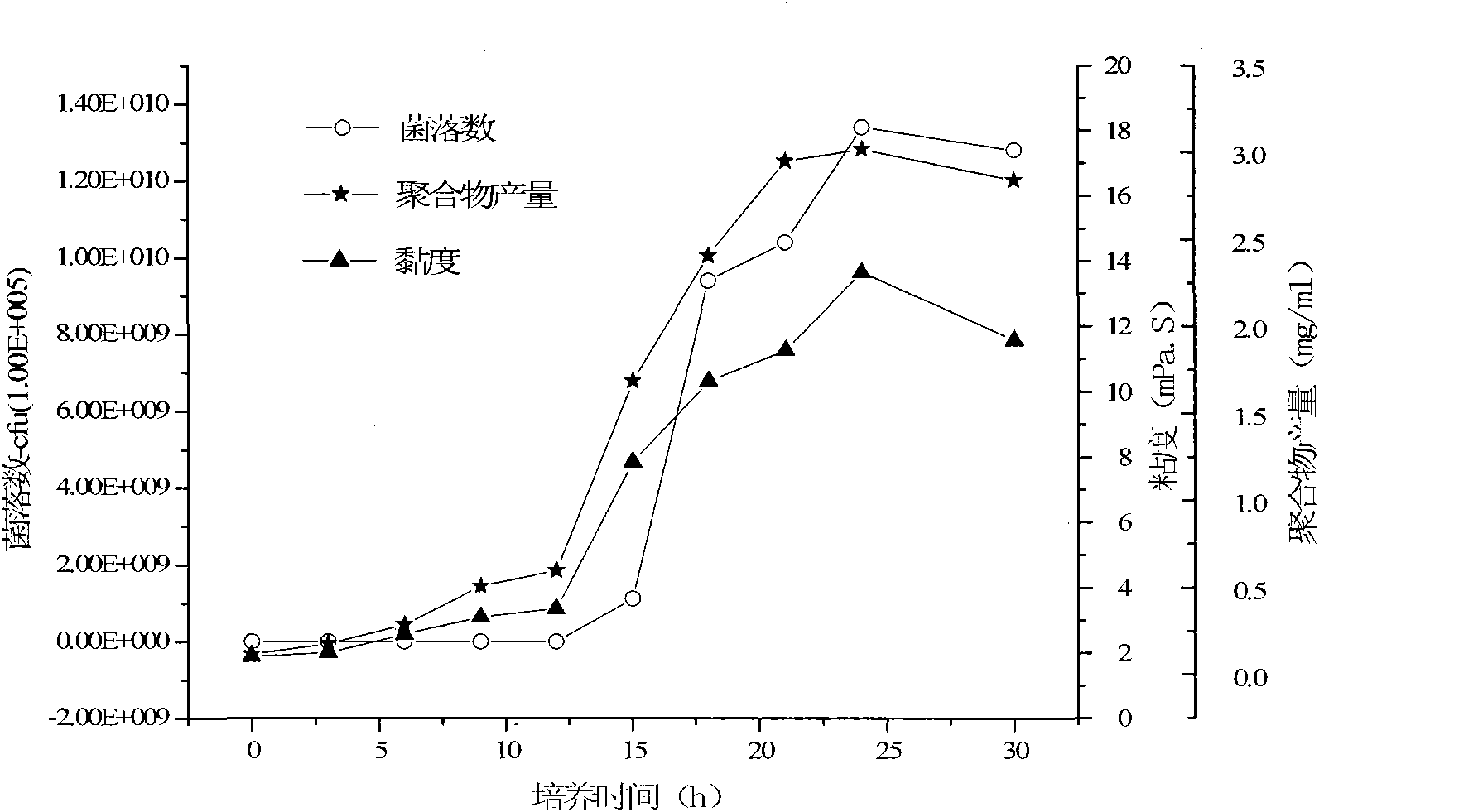

[0040] Example 3: Validation of bacterial strains producing biopolymers using gel-breaking fluid

[0041] In the invention, the surface activity and the sugar content experiment of the prepared bioactive water are carried out; the medium screening uses the surface tension value of the fermented liquid as the screening index.

[0042] The liquid fermentation medium is as follows (by weight ratio):

[0043] Guar Gum Broken Liquid Monosaccharide [β-mannanase, Bio-Thera Port (Dalian) Biotechnology Co., Ltd.] 5g, NH 4 NO 3 2.0g, K 2 HPO 4 ·3H 2 O 3.0g, NaH 2 PO 4 2H 2 O 10g, MgSO 4 ·7H 2 O0.2g, MnCl 2 4H 2 O 2ppm, yeast extract 0.2g, adjust pH=7.0 with NaOH solution.

[0044] The above-mentioned culture is inserted into the seed solution of the compound bacterial agent in step 2 of the summary of the invention according to the inoculum size 5% (V / V), and the specific composition is: peptone, 10g / L; yeast powder, 5g / L; NaCl, 5g / L; Molasses, 1% (by volume); KH 2 PO 4 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com