Photosensitive imaging liquid containing alpha-diazonium-1,3-diketone structure and used for photosensitive macromolecule flat printing plate

A technology of photosensitive polymer and imaging fluid, which is applied in the direction of photoplate making process, optics, and optomechanical equipment on the patterned surface, which can solve the problems of increasing operation steps, interference with polymerization inhibition, and increasing costs, and achieves high sensitivity and durability. High SCPG, good resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

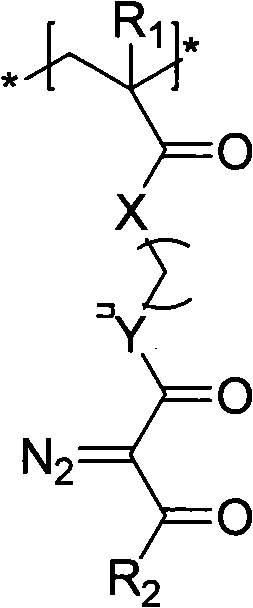

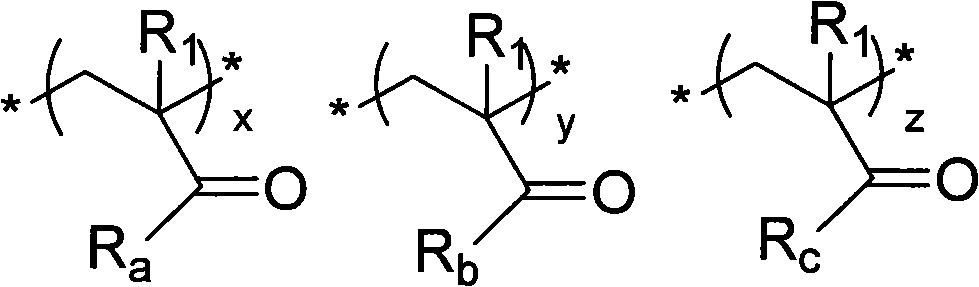

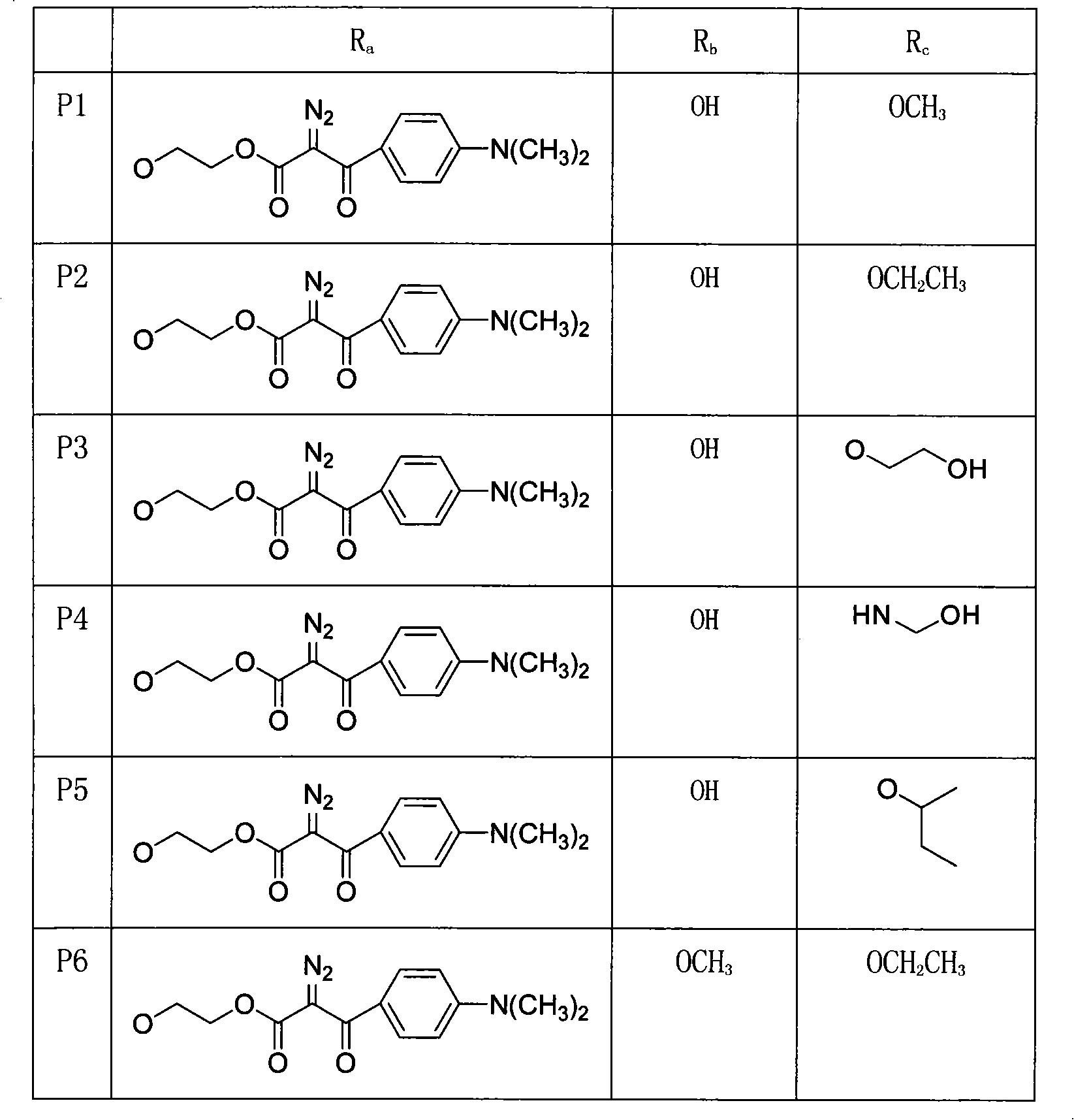

Method used

Image

Examples

Embodiment 1

[0040] The monomer methacrylic acid 2-(2-diazo-3-carbonyl-3-p-dimethylaminophenylpropionyloxy) ethyl ester 20.0 g, methyl methacrylate 8.1 g, methacrylic acid hydroxy Ethyl 7.0 grams and 0.6 grams of free radical polymerization initiator AIBN were dissolved in 500ml of tetrahydrofuran and reacted at 65°C for 30 hours; after the polymerization reaction, they were poured into petroleum ether. A large amount of solid precipitated out. Filtered and dried under vacuum at 30°C for 24 hours. A light yellow powdered solid is obtained, namely p7, where R1 is a methyl group, and the molecular formula of the obtained polymer compound is as follows, and its specific information is shown in Table 3:

[0041]

[0042] Table 3 Characterization of photosensitive polymer compound P7

[0043] Photosensitive polymer compound

[0044] When applied to positive photoresist compositions, the diazo groups of these polymer compounds will decompose when exposed to ultraviolet light, undergo Wolfe rearran...

Embodiment 2

[0046] Photosensitive polymer compound P17, where R1 is a methyl group, its synthesis method is: the monomer methacrylic acid 2-(2-diazo-3-carbonyl-3-p-dimethylaminophenylpropionyloxy) ethyl 20.0 grams of methacrylamide, 4.0 grams of methylol acrylamide and 0.7 grams of radical polymerization initiator AIBN were dissolved in 500ml of a 2:1 acetonitrile:water mixed solvent, 65 Reacted at ℃ for 32 hours; after the polymerization reaction, it was poured into acetone, a large amount of solid precipitated out, filtered, and dried under vacuum at 30℃ for 24h to obtain a pale yellow powdery solid; water for resist was used as solvent and water as developer; high sensitivity The molecular formula of the molecular compound is shown below, and the characteristics of the photosensitive polymer are shown in Table 4:

[0047]

[0048] Table 4 Characterization of photosensitive polymer compound P17

[0049] Photosensitive polymer compound

Embodiment 3

[0052] Take 35 g of BTB-26 m-cresol-formaldehyde resin produced by Taixing Dongfang Industrial Co., Ltd., the weight-average molecular weight of the m-cresol-formaldehyde resin is 4000, and the number average molecular weight is 1500, and respectively add the P7-1 obtained in Preparation Example 1 to P7-5 photosensitive polymer compound 15g, 3,5-bistrichloromethyl-1-p-methylchlorostyryltriazine 0.5g, basic brilliant blue 0.1g, cyclohexanone 300g; first dissolve each component In cyclohexanone, filter with 10μm, 5μm, 0.5μm pore size filter element to obtain photosensitive CTP ultraviolet light sensitive imaging liquid PCL1-PCL5; 2.38wt% tetramethylammonium hydroxide solution is used as developer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com