Single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and preparing method thereof

A self-crosslinking emulsion, paper-plastic composite technology, applied in the direction of adhesive types, adhesive additives, ester copolymer adhesives, etc. High strength, good water and heat resistance, good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

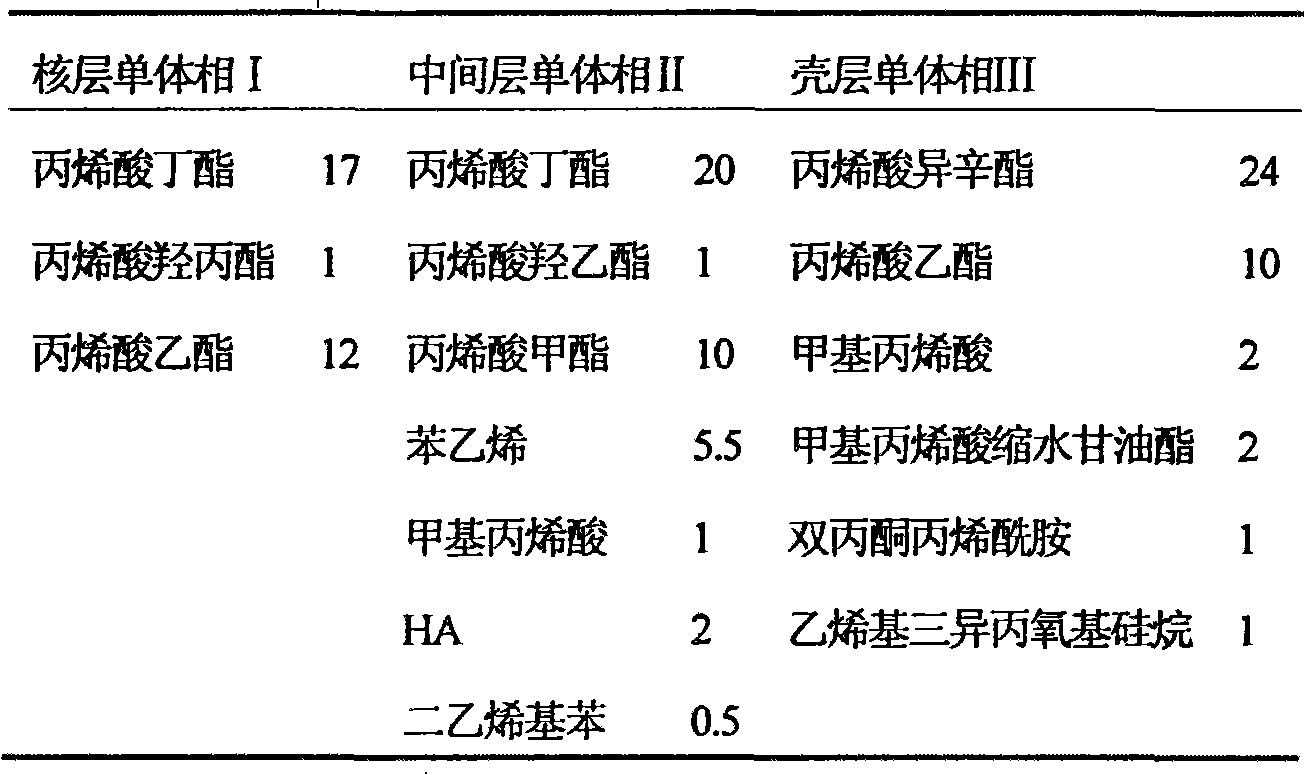

[0056] Table 1 Monomer formula of paper-plastic composite adhesive emulsion E1 (unit: g)

[0057]

[0058] Note: HA refers to the mixture of glycidyl methacrylate and acrylamide with a mass ratio of 1:1

[0059] resolve resolution:

[0060] Preparation of nuclear emulsion: first pre-emulsify 30 g of deionized water, 0.3 g of nonylphenol polyoxyethylene (10) ether ester disodium sulfosuccinate (MS21), and core layer monomer phase I to obtain pre-emulsion A; 0.4g of ammonium persulfate (APS) is prepared into an initiator solution D (APS solution D) with a concentration of 3% by weight; 0.15g of diacid block is prepared into an aqueous solution E with a concentration of 10 to 20% by weight. Add 15g of deionized water, 0.3g of buffering agent sodium bicarbonate, and 10% of the weight of APS aqueous solution D to the four-necked flask to prepare the base material, raise the temperature to 78°C, add 3% of the total weight of the pre-emulsion A of 3% by weight to react to form S...

Embodiment 2

[0066] Table 2 Monomer formula of paper-plastic composite adhesive emulsion E2 (unit: g)

[0067]

[0068] resolve resolution:

[0069] Preparation of nuclear emulsion: first pre-emulsify 32g deionized water, 0.25g ethoxylated alkyl ether ammonium sulfate (CO-436), and nuclear layer monomer phase I to obtain pre-emulsion A; take 2,2-azo 0.4 g of diisobutylamidine dihydrochloride ammonium (V50) was used to prepare an aqueous solution D with a concentration of 3% by weight; and 0.15 g of sodium bisulfite was prepared to prepare an aqueous solution E with a concentration of 10-20% by weight. Add 12g deionized water, 0.3g buffering agent sodium bicarbonate, and 10% of the total weight of APS aqueous solution D to the four-necked flask to prepare the base material, raise the temperature to 75°C, add 8% of the total weight of pre-emulsion A to react to form a seed emulsion; Raise the temperature to 78°C, start to add the remaining pre-emulsion A dropwise, and simultaneously add ...

Embodiment 3

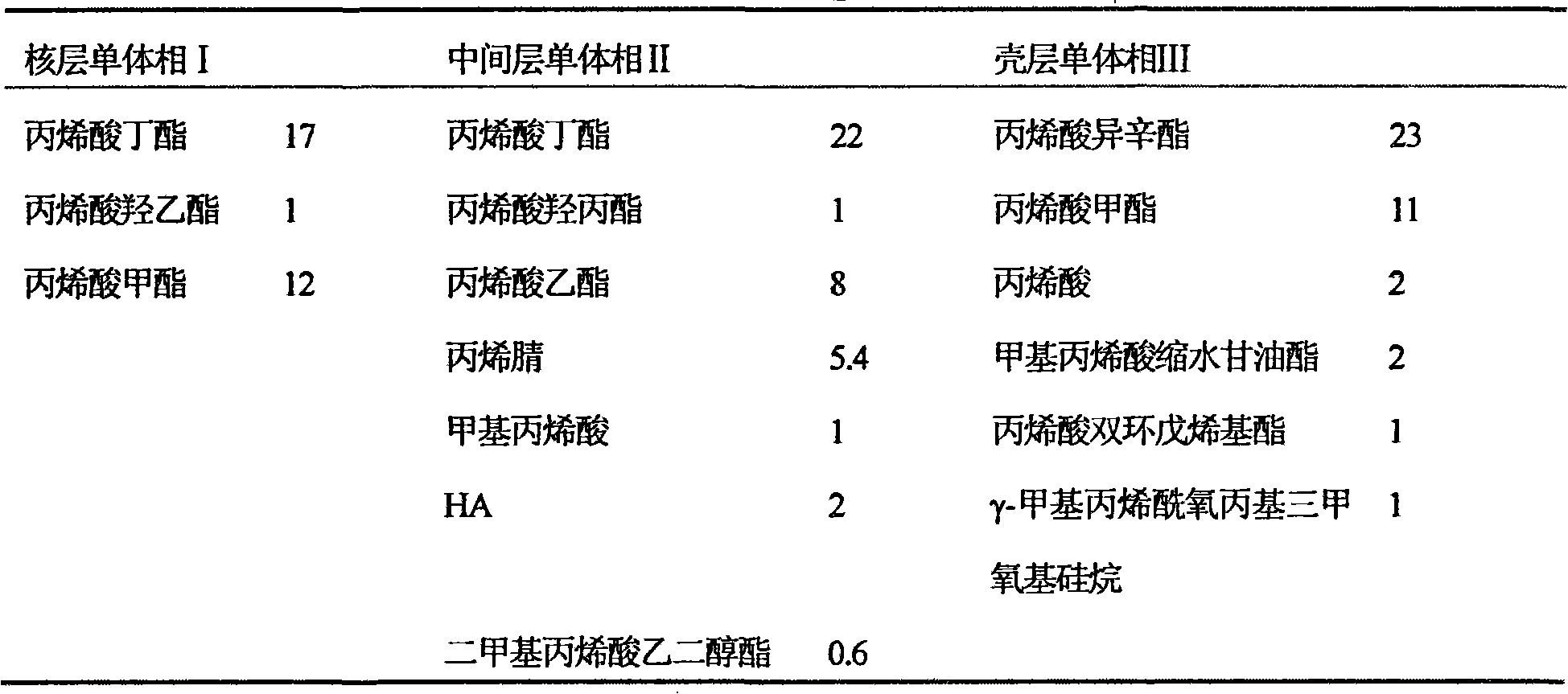

[0076] Table 3 Monomer formula of paper-plastic composite adhesive emulsion E3 (unit: g)

[0077]

[0078] resolve resolution:

[0079] Preparation of nuclear emulsion: first pre-emulsify 32g deionized water, 0.3g disodium ethoxysulfosuccinate, and nuclear layer monomer phase I to obtain pre-emulsion A; take 0.4g ammonium persulfate (APS) to prepare the weight percentage The concentration is 3% initiator aqueous solution D; take 0.15g Diaobai block to prepare aqueous solution E with a concentration of 10-20% by weight. Add 18g of deionized water, 0.3g of buffering agent sodium bicarbonate, and 10% of the total weight of APS aqueous solution D to the four-necked flask to prepare the base material, raise the temperature to 80°C, and add 8% of the total weight of pre-emulsion A to react to form a seed emulsion; Raise the temperature to 82°C, start to add the remaining pre-emulsion A dropwise, and simultaneously add 30% of the total weight of the APS aqueous solution D dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com