Novel bonder for lithium ion batteries

A lithium-ion battery and binder technology, which is applied in the direction of non-polymer binder additives, adhesives, battery electrodes, etc., can solve the problems of relatively large shrinkage difference, increased charge and discharge load, and poor load characteristics. Achieve the effect of improving charge and discharge capacity, good film forming, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation process of the binder for the novel lithium-ion battery of the present embodiment is as follows:

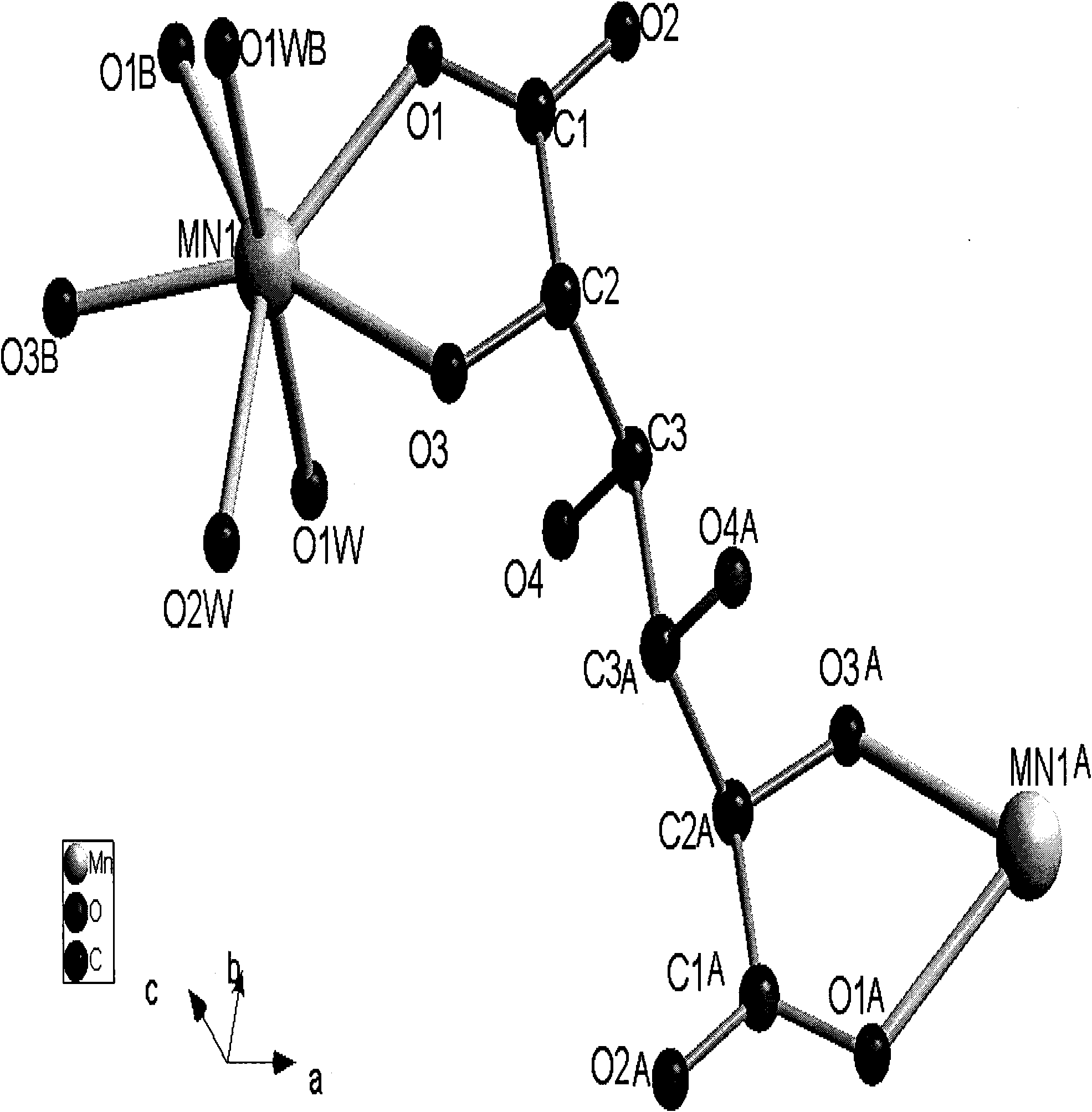

[0021] 1. Preparation of Manganese Mucic Acid Complex Powder

[0022] (1) Manganese acetate and mucus acid were dissolved in an aqueous solution at a molar ratio of 1:1, fully stirred, and reacted at 80° C. for 4 hours to obtain a manganese mucus acid complex solution.

[0023] (2) Add an appropriate amount of ethanol, lower the temperature and cool down, let stand for precipitation, filter, wash, and dry to obtain white mucus acid manganese complex powder.

[0024] 2. Preparation of binder for lithium-ion batteries

[0025] 8% manganese mucus acid complex, 90% vinylidene fluoride, and 2% tetrafluoroethylene copolymer are used as binders.

[0026] The use of the binder can increase the charging and discharging capacity of the carbon-coated lithium iron phosphate lithium battery cathode material by about 3%.

Embodiment 2

[0028] 1. Preparation of Manganese Mucic Acid Complex Powder

[0029] (1) Manganese chloride and mucus acid are dissolved in an aqueous solution at a molar ratio of 1:1, fully stirred, and reacted at 60° C. for 6 hours to obtain a manganese mucus acid complex solution.

[0030] (2) Add appropriate amount of ethanol and N, N-dimethylformamide in sequence, cool down, let stand for precipitation, filter, wash and dry to obtain white mucoic acid manganese complex powder.

[0031] 2. Preparation of binder for lithium-ion batteries

[0032] 2% of manganese complex of mucus acid, 75% of vinylidene fluoride, 20% of tetrafluoroethylene, 3% of propylene are used as binder. The binder has good flexibility and chemical stability. The binder has good charge-discharge cycle characteristics.

Embodiment 3

[0034] 1. Preparation of Manganese Mucic Acid Complex Powder

[0035] (1) Manganese nitrate and mucus acid were dissolved in an aqueous solution at a molar ratio of 1:1, fully stirred, and reacted at 50° C. for 7 hours to obtain a manganese mucus acid complex solution.

[0036] (2) Add an appropriate amount of ethanol, lower the temperature and cool down, let stand for precipitation, filter, wash, and dry to obtain white mucus acid manganese complex powder.

[0037] 2. Preparation of binder for lithium-ion batteries

[0038] 70% vinylidene fluoride, 26% chlorotrifluoroethylene copolymer and 4% mucus acid manganese complex powder are blended to form a binder, which can improve the binding of the electrode active mixture and the collector It can prevent the electrode material from falling off and improve the cycle characteristics of the battery to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com