Smelting furnace

A furnace and hearth technology, applied in the field of smelting furnaces, can solve the problems of increased steelmaking cost, energy waste, and high flue gas temperature, and achieve the effects of improving combustion power and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

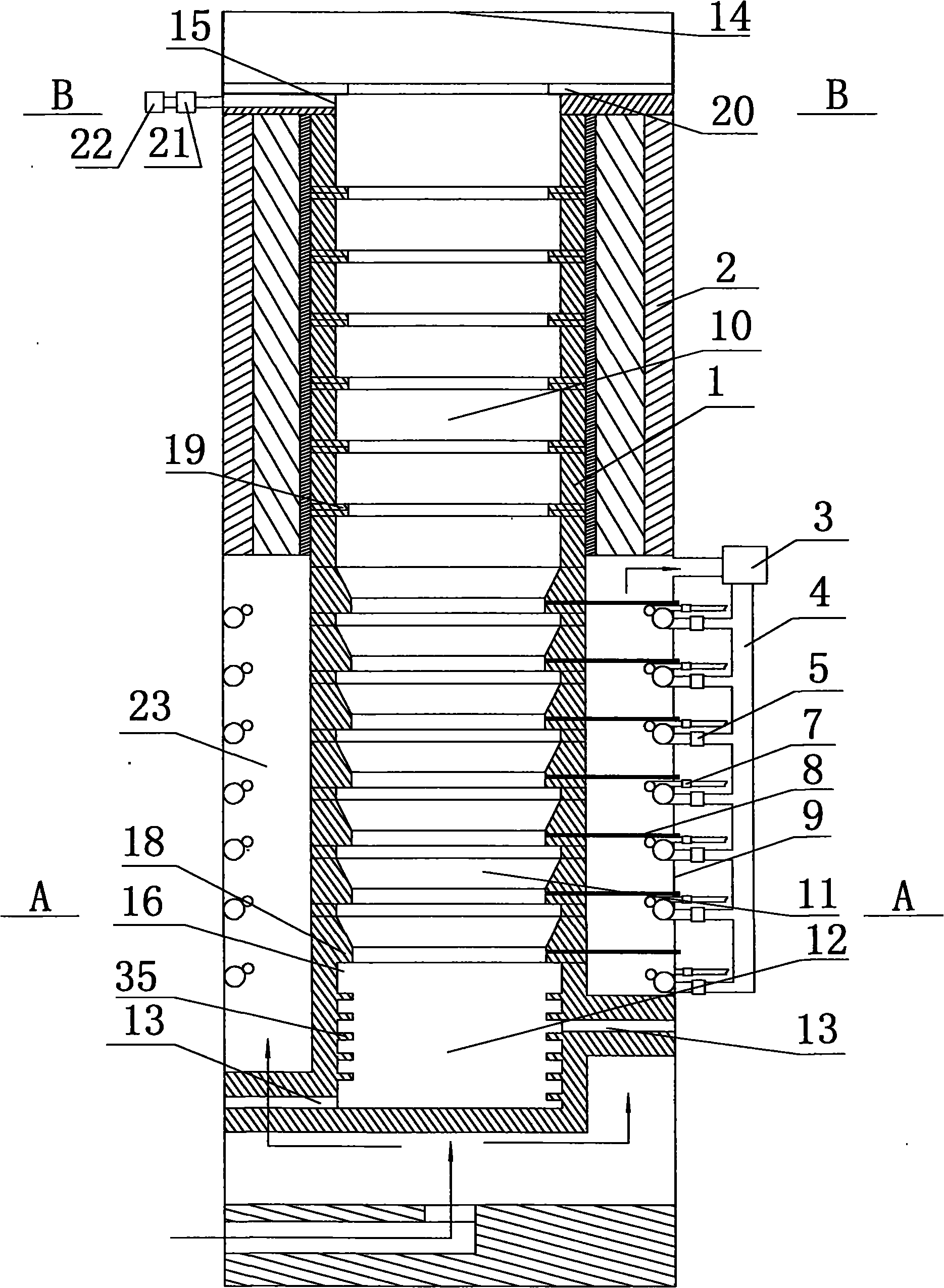

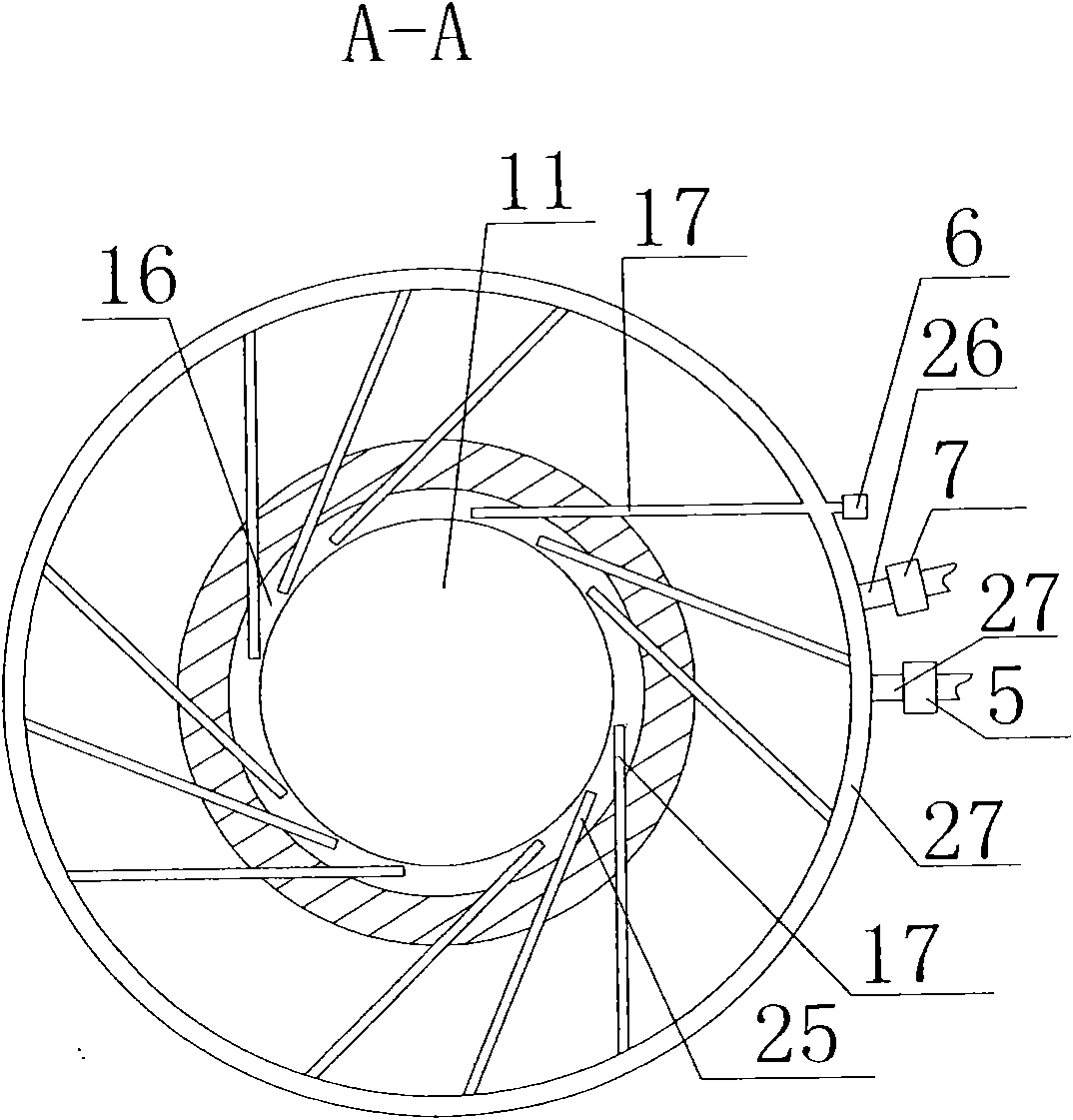

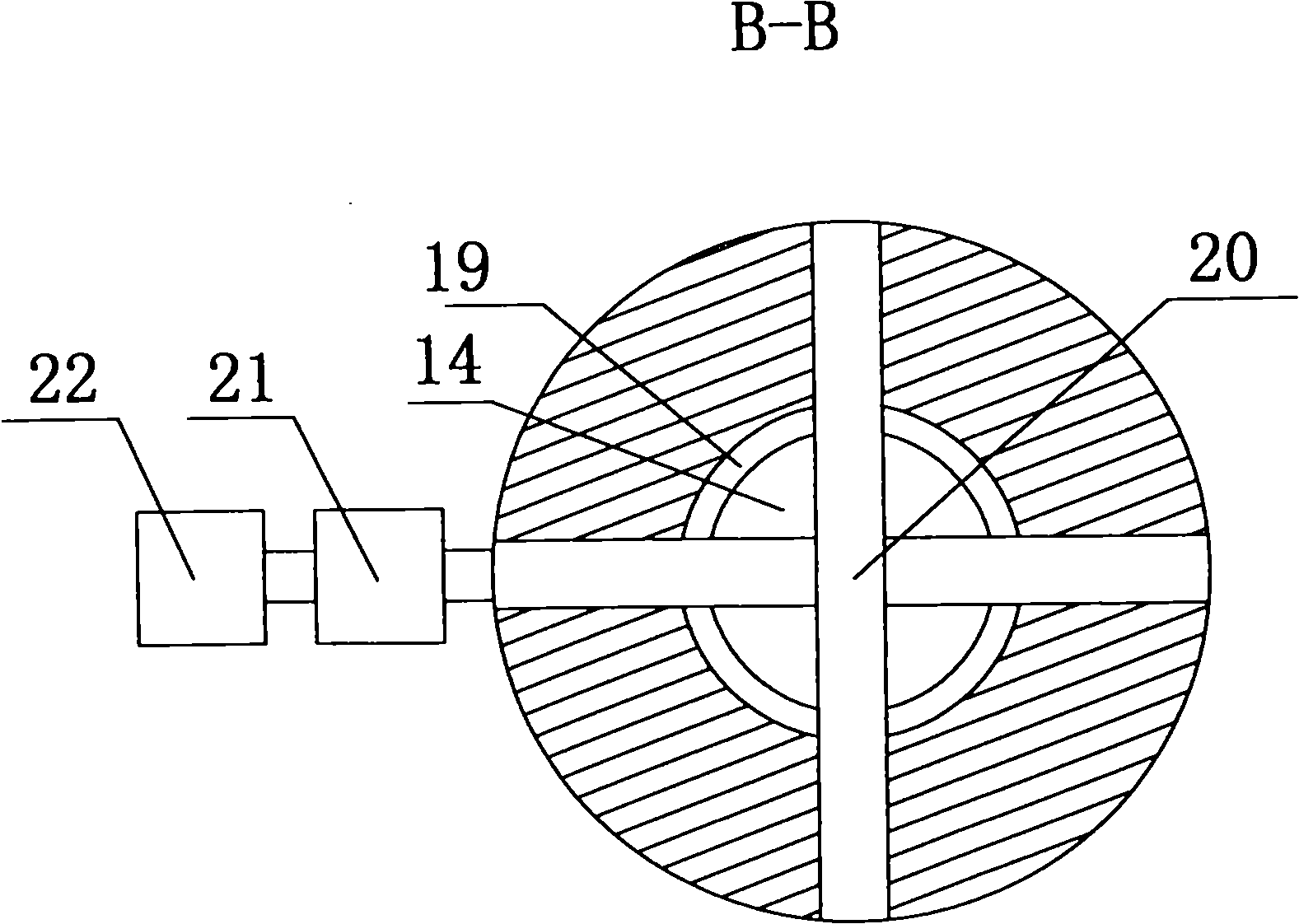

[0016] The main structure of the present invention is: smelting furnace, including: refractory material 1, heat preservation material 2, fan 3, pipeline 4, valve 5, ignition hole 6, fuel supply device 7, temperature measuring device 8, furnace chamber 9 is provided with heating chamber 10 And the smelting chamber 11, the heating chamber 10 bottom communicates with the smelting chamber 11, the melting chamber 11 bottom is provided with a hearth 12, the furnace hearth 12 is provided with a hearth discharge port 13, the heating chamber 10 top is provided with a heating chamber feed port 14, and the heating chamber 10 top A heating chamber gas outlet 15 is provided, and a plurality of fire passages 16 are arranged around the inner wall of the smelting chamber 11 , and a plurality of air intake passages 17 are arranged on the side walls of the fire passage 16 , and the air intake passages 17 communicate with the fire passages 16 .

[0017] The furnace chamber 9 can be made into a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com