Process for a reduction in the amount of sulphur compounds, hydrogen cyanide and formic acid in synthesis gas

A synthesis gas and compound technology, applied in the field of producing other compounds such as methanol, dimethyl ether or hydrocarbon gas, can solve the problem of harmful execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

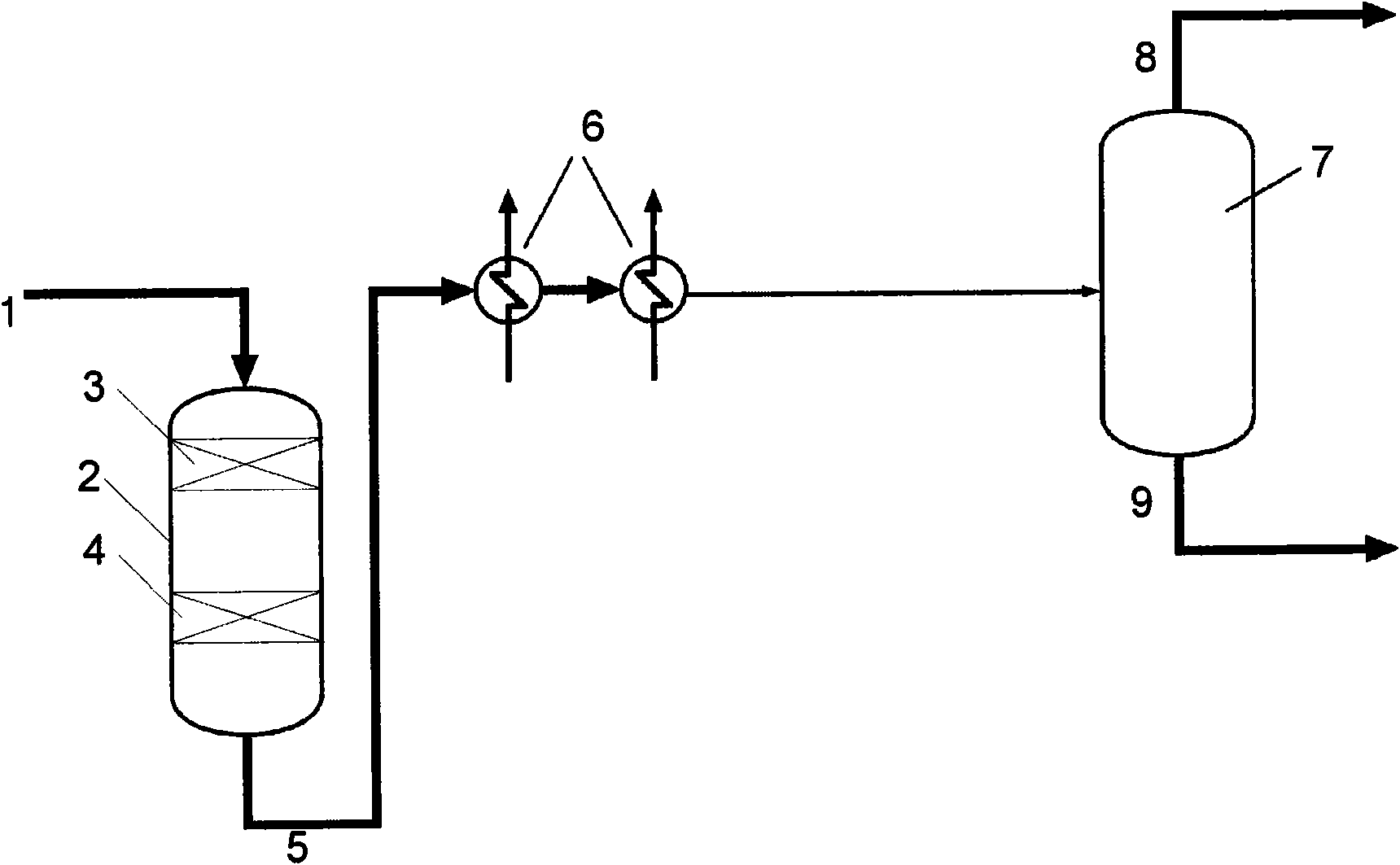

Method used

Image

Examples

Embodiment 1

[0085] Make containing 10 volume ppm H 2 A gas of S and 20% by volume steam is contacted with zinc oxide at 200°C. The concentration of S-compounds obtained in the synthesis gas in the dry gas was 3.2 ppb by volume.

Embodiment 2

[0087] Make containing 10 volume ppm H 2 A gas of S and 50% steam by volume is contacted with zinc oxide at 200°C. The concentration of S-compounds obtained in the syngas in the dry gas was 10 ppb by volume.

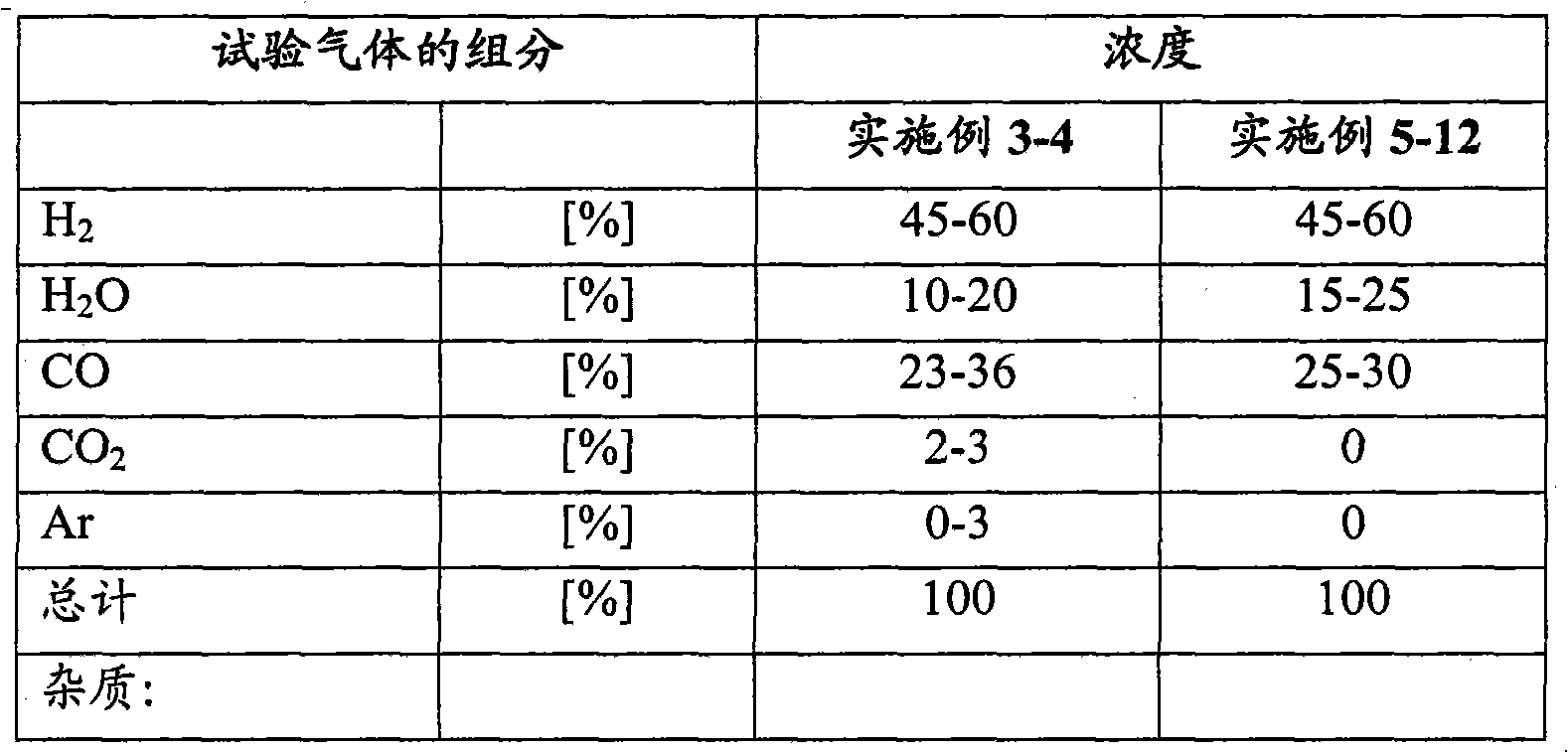

[0088] Operation of Embodiment 3-12

[0089] Experiments with different catalysts were carried out using synthesis gas mainly composed of hydrogen, carbon monoxide, carbon dioxide, the composition of which corresponds to that of the synthesis gas from the autothermal reforming unit.

[0090] The impurity was prepared as follows: Hydrogen cyanide was prepared by acid distillation of sodium cyanide. The formic acid used was analytical grade 32% formic acid solution. The ammonia used was 25% ammonia solution (analytical grade).

[0091] The impurities hydrogen cyanide, ammonia and formic acid were then added to the feed water to the test unit evaporator. The amount of impurities in the synthesis gas corresponds to the amount expected in the synthesis gas from the autot...

Embodiment 3

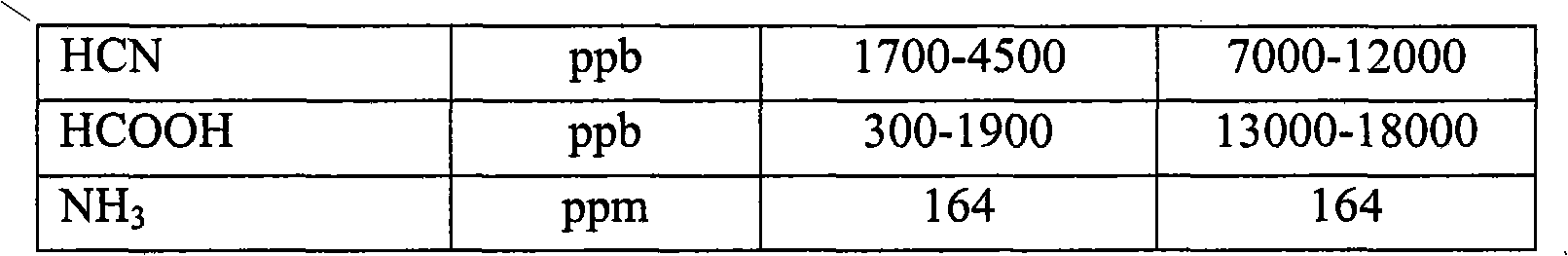

[0110] 7% by weight silver on titania was prepared by impregnating porous 3 mm titania particles with an aqueous solution containing 22.1 g of silver nitrate per 100 ml of solution. The impregnated titanium oxide was dried at 110°C, followed by silver nitrate decomposition at 500°C for 1 hour. Catalysts were tested at low and high space velocities. The results are shown in Table 2.

[0111] Table 2

[0112]

[0113] As shown in Table 2, silver added to TiO 2 Reduce the concentration of formic acid and derivatives by more than 60%.

[0114] There are some water gas shift reactions that take place over the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com