External wall body thermal insulation decorative board and preparation method thereof

A technology for thermal insulation decorative panels and walls, applied in covering/lining, layered products, buildings, etc., can solve the problems of unsatisfactory flame retardancy and durability, poor water resistance and weather resistance, poor thermal insulation performance, etc., and achieve fireproof performance Safe and reliable, strong self-cleaning, abundant reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

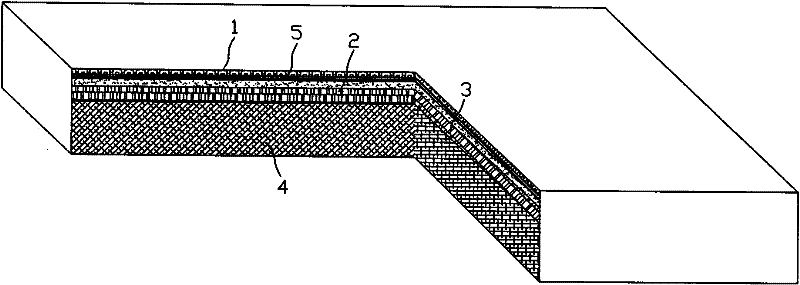

[0037] Embodiment 1 A kind of exterior wall thermal insulation decorative board, see figure 1 , including a finish layer 1, a glass fiber layer 5, a magnesite material layer 2 (3mm), a reinforcement layer 3 (2.5mm) and an inorganic hybrid heat-insulation layer 4 (40mm) are sequentially arranged on the inside of the finish layer. The reinforcement layer 3 is a net of bamboo strips. The veneer layer 1 can be set as a wood-imitation layer, or a metal texture-imitation layer, or a brick-imitation layer. Using molding technology, the veneer can be made into rich shapes according to needs, such as imitation brick, imitation wood, imitation stone, imitation metal, etc.

[0038] Bamboo is light and strong, and has strong bending and tensile strength. The mechanical measurement of bamboo shows that the shrinkage of bamboo is very small, but the elasticity and toughness are extremely strong. The compressive strength along the grain is about 800 kilograms per square centimeter; the ten...

Embodiment 2

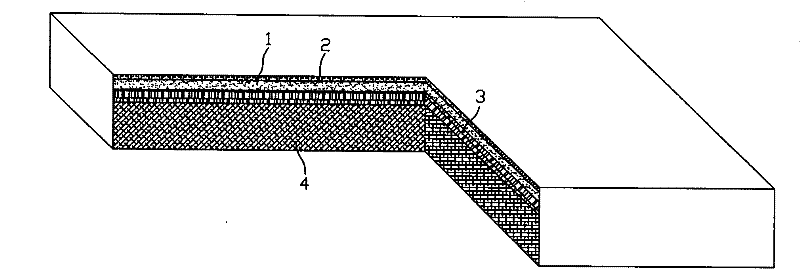

[0050] Embodiment 2 An insulating decorative panel for an exterior wall, which is basically the same as in Embodiment 1, except that: the reinforcement layer is a reed net (woven from reed stalks); the inorganic mixed filler It is made by uniformly mixing the following raw materials: 100kg of magnesium oxide powder, 120kg of magnesium chloride aqueous solution with a Baume degree of 28, 90kg of medium sand (0.35-0.5mm), 130kg of quartz stone (3-5mm in size), 50kg of vitrified microbeads, glass Fiber (length 3-5mm) 8kg, aluminum potassium sulfate 2kg, mica powder 14kg, fly ash (20-60 mesh) 7kg, OP-102.5kg, modifier 2.5kg. Chinese reed is an ideal building material, not only good in heat and sound insulation, but also moisture-proof. Chinese reed grows fast, can grow 5 cm per day, and has abundant resources.

Embodiment 3

[0051] Embodiment 3 An insulating and decorative panel for an exterior wall, which is basically the same as in Embodiment 1, except that the ribbed layer is a corn stalk husk net (woven from corn stalk husk); the inorganic mixture The filling material is uniformly mixed with the following raw materials: 100kg of magnesium oxide powder, 100kg of magnesium chloride aqueous solution with a Baume degree of 23, 70kg of medium sand (0.35-0.5mm), 120kg of quartz stone (3-5mm in size), and 20kg of vitrified microbeads , glass fiber (length 3 ~ 5mm) 4kg, aluminum potassium sulfate 1kg, mica powder 13kg, fly ash (20 ~ 60 mesh) 6kg, OP-101.5kg, modifier 1.5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com