Environment-friendly flame retardant PBT/PC composite material and preparation method thereof

A composite material and environmentally friendly technology, applied in the field of environmentally friendly flame-retardant PBT/PC composite materials and their preparation, can solve problems such as poor interface bonding, achieve excellent mechanical properties and flame-retardant properties, high surface gloss, and dimensional stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 10

[0034] After dispersing and mixing PBT, PC, transesterification inhibitor, flame retardant, toughening compatibilizer and processing aid in a high-speed mixer in proportion, glass fiber is added to the side feed, melted and mixed by a twin-screw extruder , extrusion, cooling, pelletizing, drying and packaging. The length-to-diameter ratio of twin-screw extrusion is 40:1, the temperature of each stage of the screw is 240 to 270° C., and the rotational speed of the screw is 400 rpm / min. The composite materials prepared in each embodiment were injection molded into test specimens according to the standard size, the mechanical properties were tested according to the SIO international standard, and the flame retardancy was tested according to the UL94 standard.

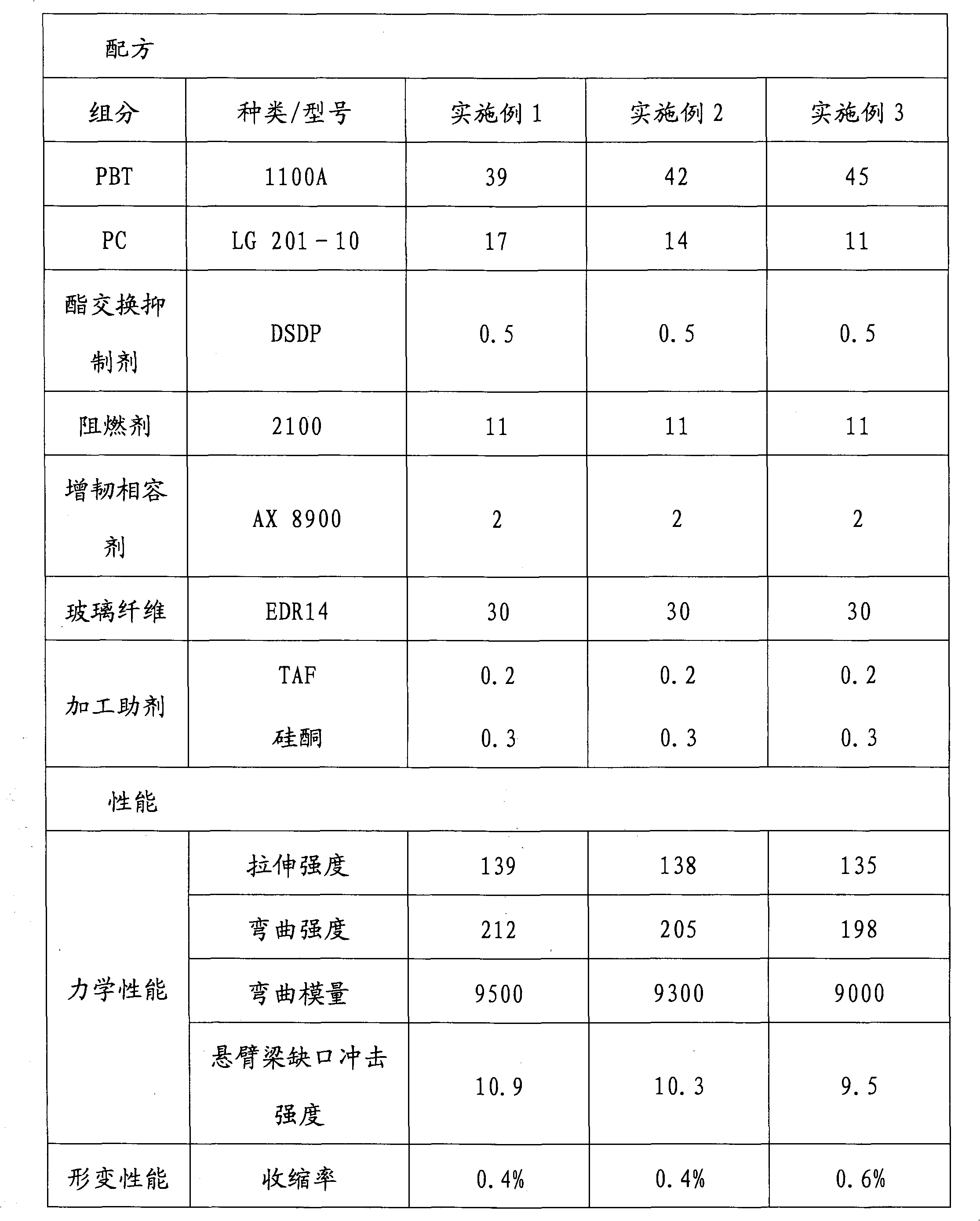

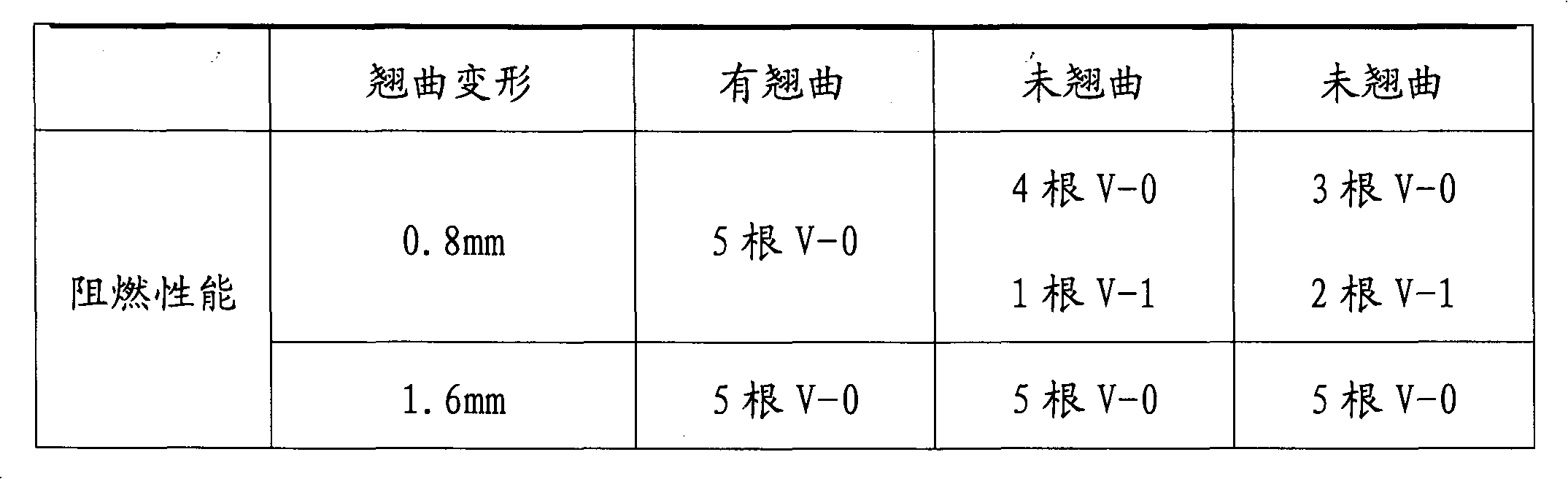

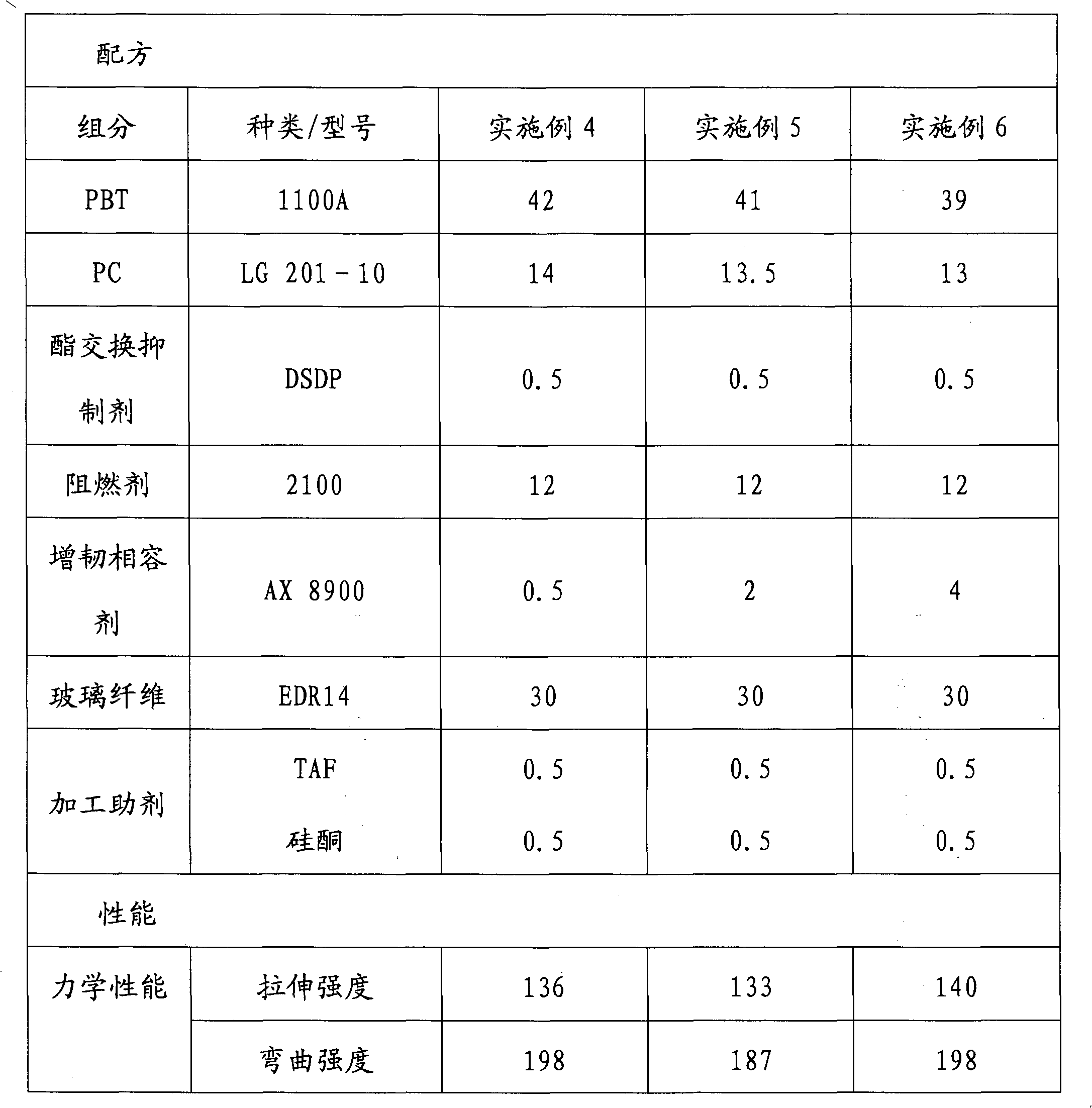

[0035] Examples 1 to 3 verified different PBT / PC ratios, and the detailed ratios and test data results are shown in Table 1. Examples 4 to 6 verified the dosage of the impact modifier, and other components were changed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com