Mildew-proof and antibacterial sole polyurethane stock solution and production process of polyurethane sole

A polyurethane and stock solution technology, applied in the field of materials, can solve the problems of fracture, no anti-mildew and anti-bacterial function, cracking of soles, etc., and achieve the effects of simple process, excellent anti-bacterial and anti-mildew properties, and excellent anti-bacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

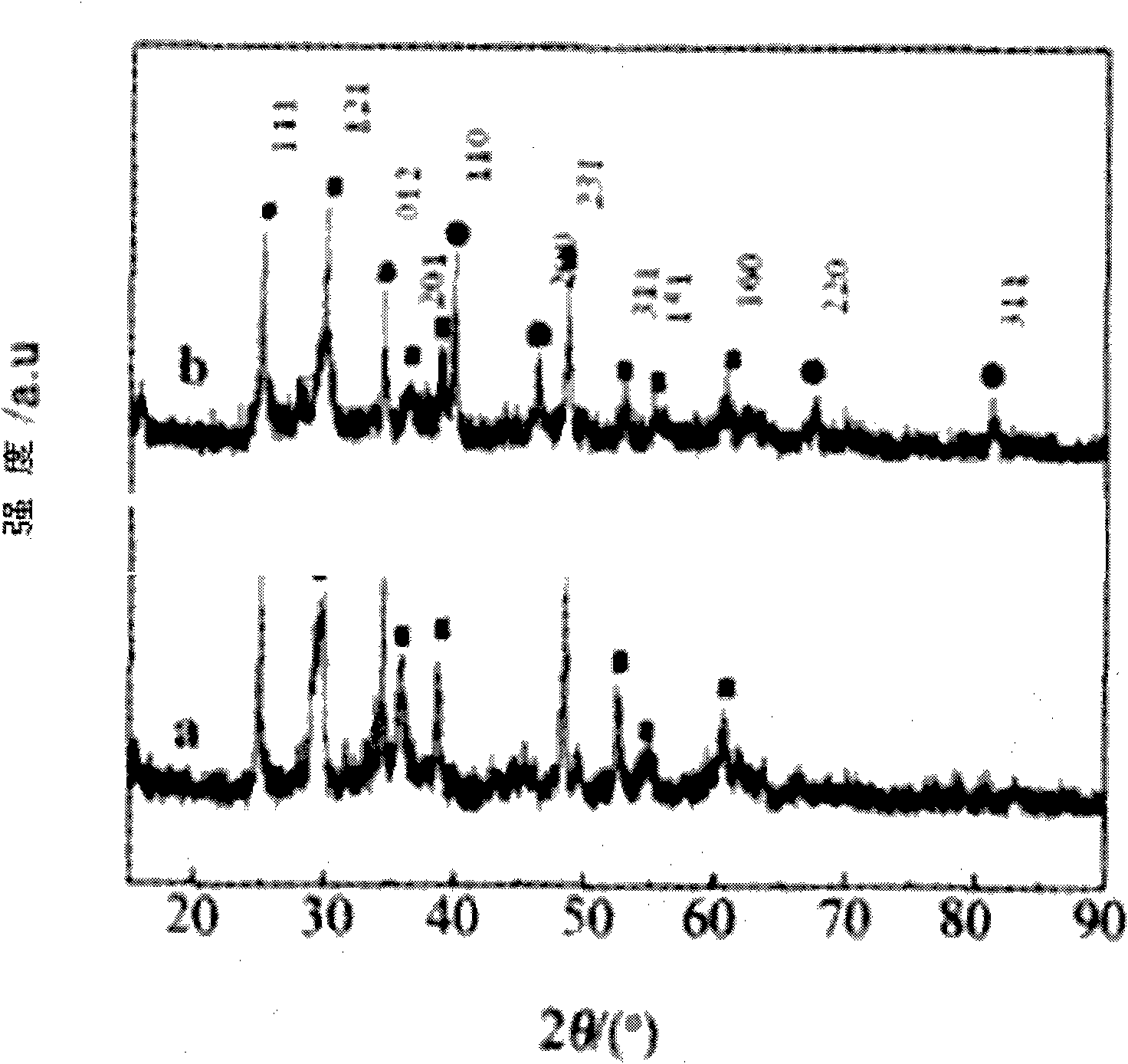

[0023] A cobalt / plate titanium nano-titanium dioxide composite, which is prepared by the following steps: first, add 0.5g titanium dioxide powder, 7.5mL absolute ethanol and 7.5mL10mol / L sodium hydroxide solution in a clean beaker, stir for 1h and transfer Put it into the reaction kettle, make the hydrothermal reaction at 180°C, take it out after 18 hours of reaction, cool it down to room temperature naturally, then add 0.52L of 1.2mmol / L cobalt nitrate solution into the reaction kettle, after ultrasonic dispersion, let it cool at 150°C Undertake the hydrothermal reaction for 8 hours, and finally wash the hydrothermal reaction product with 0.1mol / L HCl solution and deionized water to neutrality, and dry at 80°C to obtain the cobalt / brockite nano-titanium dioxide composite, wherein cobalt and The molar ratio of titanium is 1:10.

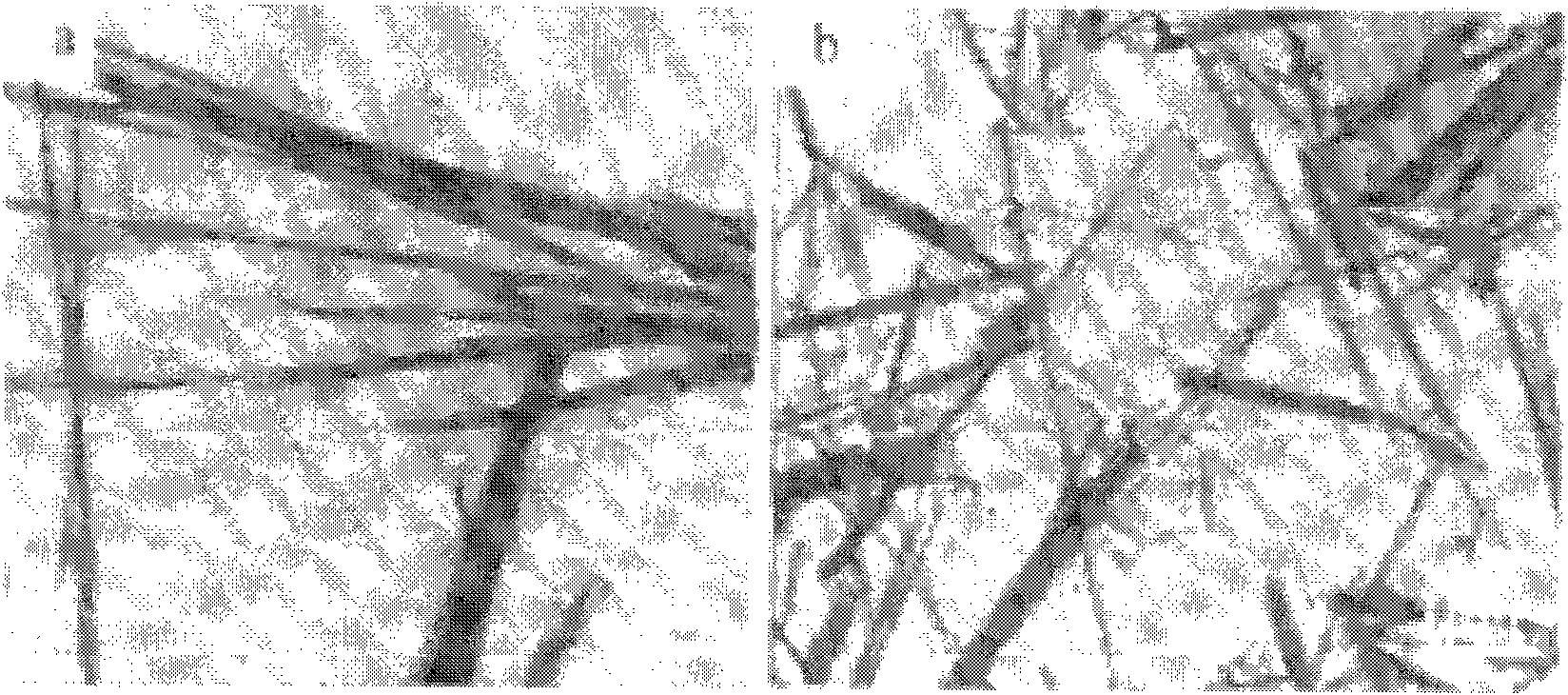

[0024] Get titanium dioxide nanowires (the product after the first hydrothermal reaction) and the prepared cobalt / platelet titanium nano-titanium c...

Embodiment 2

[0027] A cobalt / brookite nano-titanium dioxide composite, the preparation method of which is basically the same as in Example 1, except that the molar ratio of titanium dioxide to cobalt nitrate is 1:5-6.

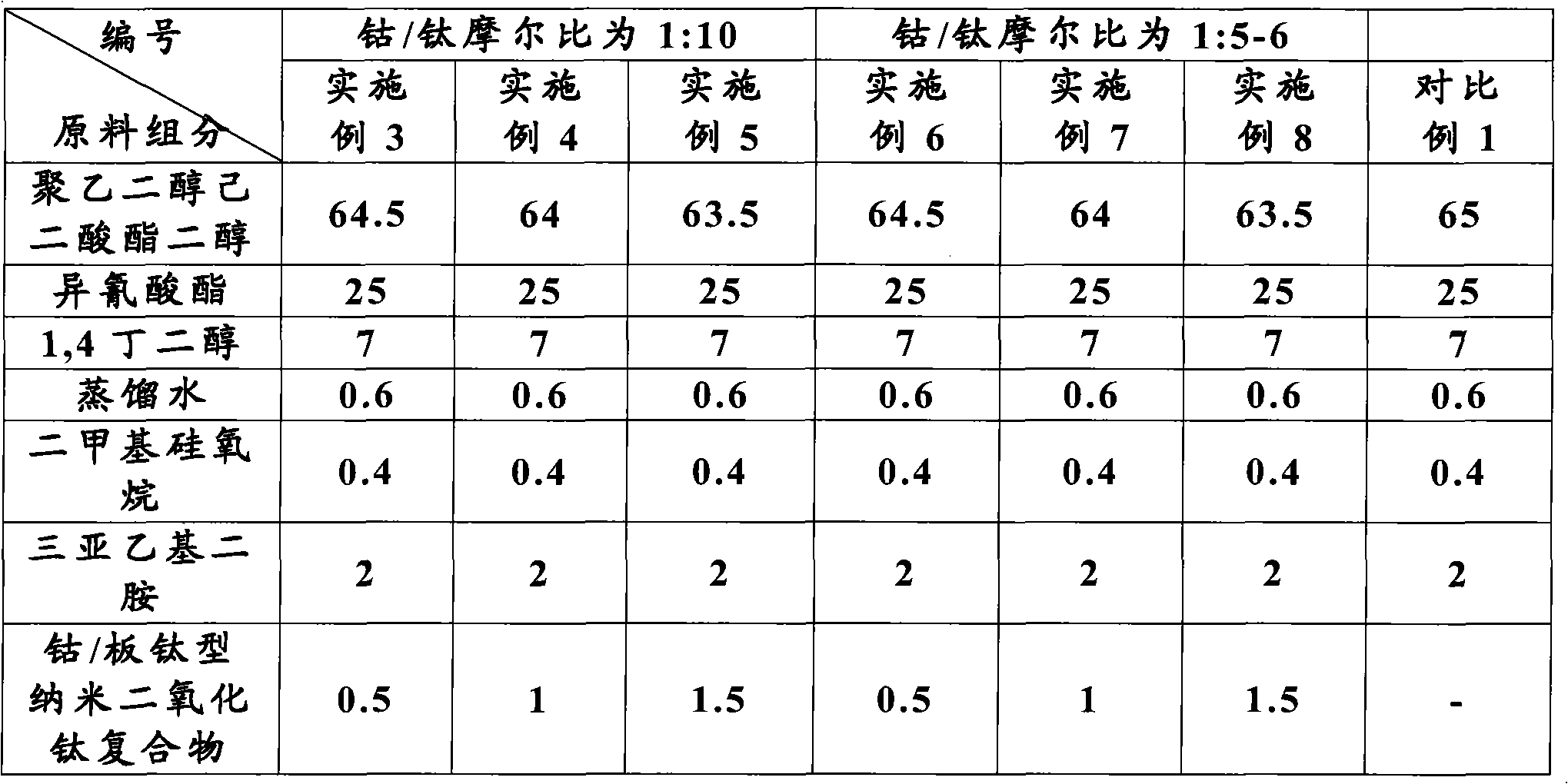

[0028] The process of producing polyurethane shoe soles using the polyurethane stock solution of Examples 1 and 2 can be described more specifically through the following Examples 3-8 and Comparative Example 1.

[0029] Embodiment 3~8 and comparative example 1 all account for the mass percent example of polyurethane sole stock solution according to the raw material described in table 1, prepare polyurethane sole according to the following steps:

[0030] (1), Synthetic polyurethane prepolymer component: Add 25 parts by weight of isocyanate and 20 parts by weight of polyethylene glycol adipate diol with a number average molecular weight of 2000 in sequence in the reactor, and control the temperature of the reactor at 70°C ~80°C, heat preservation reaction for 3 hours and mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com