Dual self-healing modification method for silicon carbide ceramic matrix composite material

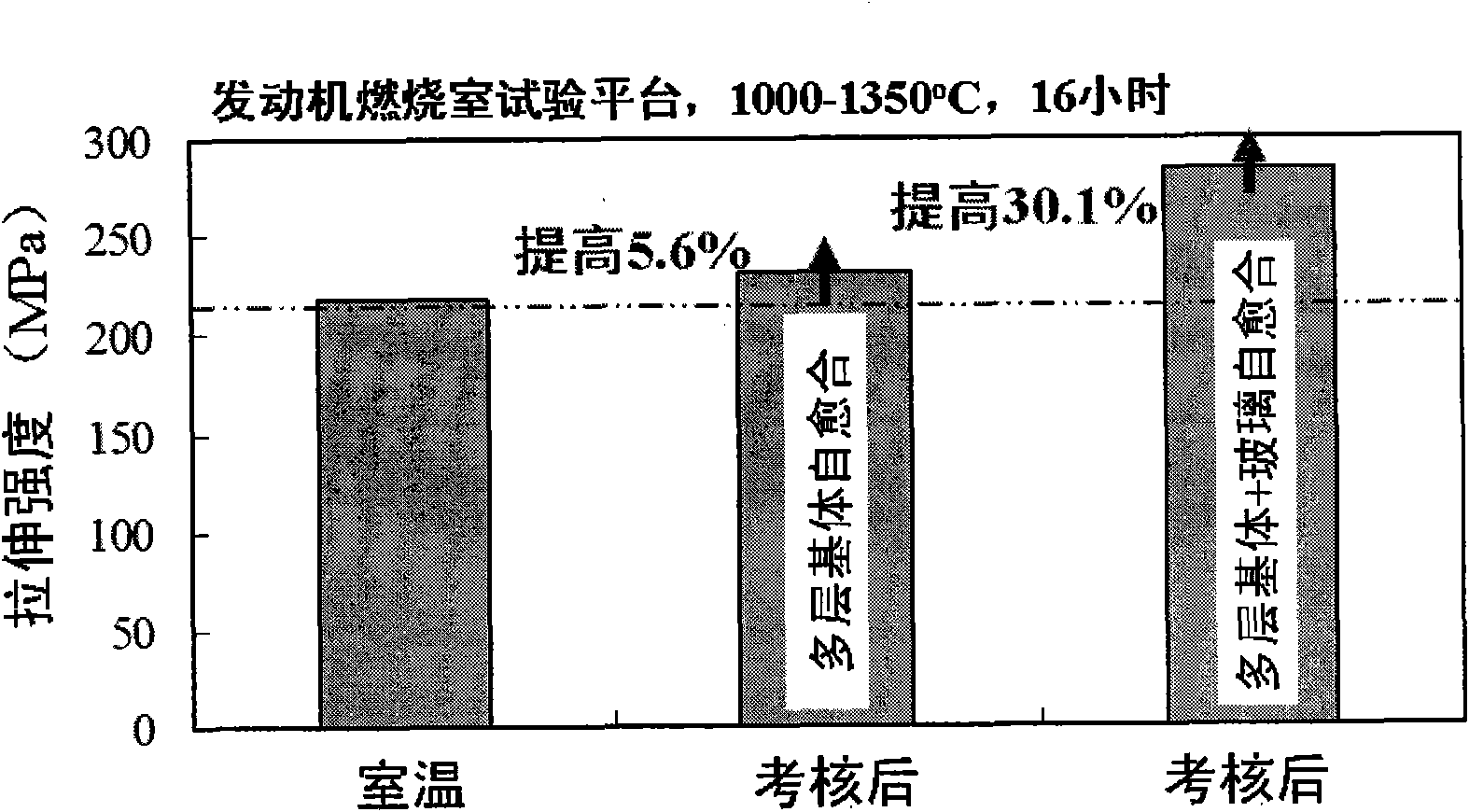

A technology of silicon carbide ceramic matrix and composite materials, which is applied in the field of double self-healing modification of multi-layer amorphous boron carbide matrix combined with borosilicate glass sealing, can solve the problems of no public reports and other problems, and achieve designable Strong resistance, reduced matrix cracks, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Use carbon fiber with the brand name T700 as the reinforcement of the composite material, and weave it into a 3D fiber prefabricated body using a three-dimensional four-way weaving method. The prefabricated body size is 250.0mm×125.0mm, and the thickness is 2.0mm;

[0028] (2) The prefabricated body is shaped by a high-strength, high-modulus graphite mold, and the thickness of the fiber prefabricated body is 4.0mm;

[0029] (3) Put the carbon fiber preform into the chemical gas phase pyrolysis carbon infiltration furnace, infiltrate the pyrolysis carbon interface layer, infiltration temperature: 750 ° C, holding time: 200h, furnace pressure: 150Pa, precursor body is C 3 h 6 ; its thickness is 150nm;

[0030] (4) High temperature treatment is performed on the preform after the interface layer is prepared, the treatment temperature is 1750°C, the treatment atmosphere is Ar gas, and the treatment time is 2.0 hours;

[0031] (5) Put the preform after high temperature ...

Embodiment 2

[0038] (1) Use carbon fiber with the brand name T300 as the reinforcement of the composite material, and weave the fiber into a 2.5-dimensional fiber prefabricated body. The length and width of the prefabricated body are 250mm×125mm, and the thickness is 4.5mm;

[0039] (2) The 2.5-dimensional carbon fiber braided prefabricated body is directly fixed and formed with a graphite mold;

[0040] (3) Put the carbon fiber prefabricated body into the chemical vapor phase silicon carbide infiltration furnace to infiltrate the pyrolytic carbon interface layer, infiltration temperature: 1000°C, holding time: 80h, furnace pressure: 100Pa, the precursor is CH 4 ; its thickness is 250nm;

[0041] (4) High temperature treatment is performed on the carburized preform, the treatment temperature is 2050°C, the treatment atmosphere is Ar gas, and the treatment time is 1.0 hour;

[0042] (5) Put the preform after high temperature heat treatment into the chemical vapor phase silicon carbide infi...

Embodiment 3

[0049] (1) Using Nicalon silicon carbide (SiC) fiber as the reinforcement of the composite material, the 2-dimensional Nicalon fiber cloth is laid into a 2-dimensional laminated prefabricated body. The length and width of the prefabricated body are 380mm×380mm, and the thickness is 5.0mm ;

[0050] (2) The 2-dimensional laminated prefabricated body is directly fixed and formed with a graphite mold;

[0051] (3) Put the silicon carbide fiber preform into the chemical vapor phase silicon carbide infiltration furnace to infiltrate the pyrolytic carbon interface layer, infiltration temperature: 900°C, holding time: 200h, furnace pressure: 10Pa, the precursor is CH 4 ; its thickness is 300nm;

[0052] (4) Carburizing the preform after high temperature treatment, treatment temperature: 1300°C, treatment atmosphere: Ar gas, treatment time 2.0 hours;

[0053] (5) Put the prefabricated body after high temperature heat treatment into a chemical vapor phase silicon carbide infiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com