Bulk silicon etching and gold silicon bonding combined process method

A composite process and bonding technology, applied in metal material coating process, process for producing decorative surface effects, decorative arts, etc., can solve the problems of redundancy and many process flows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

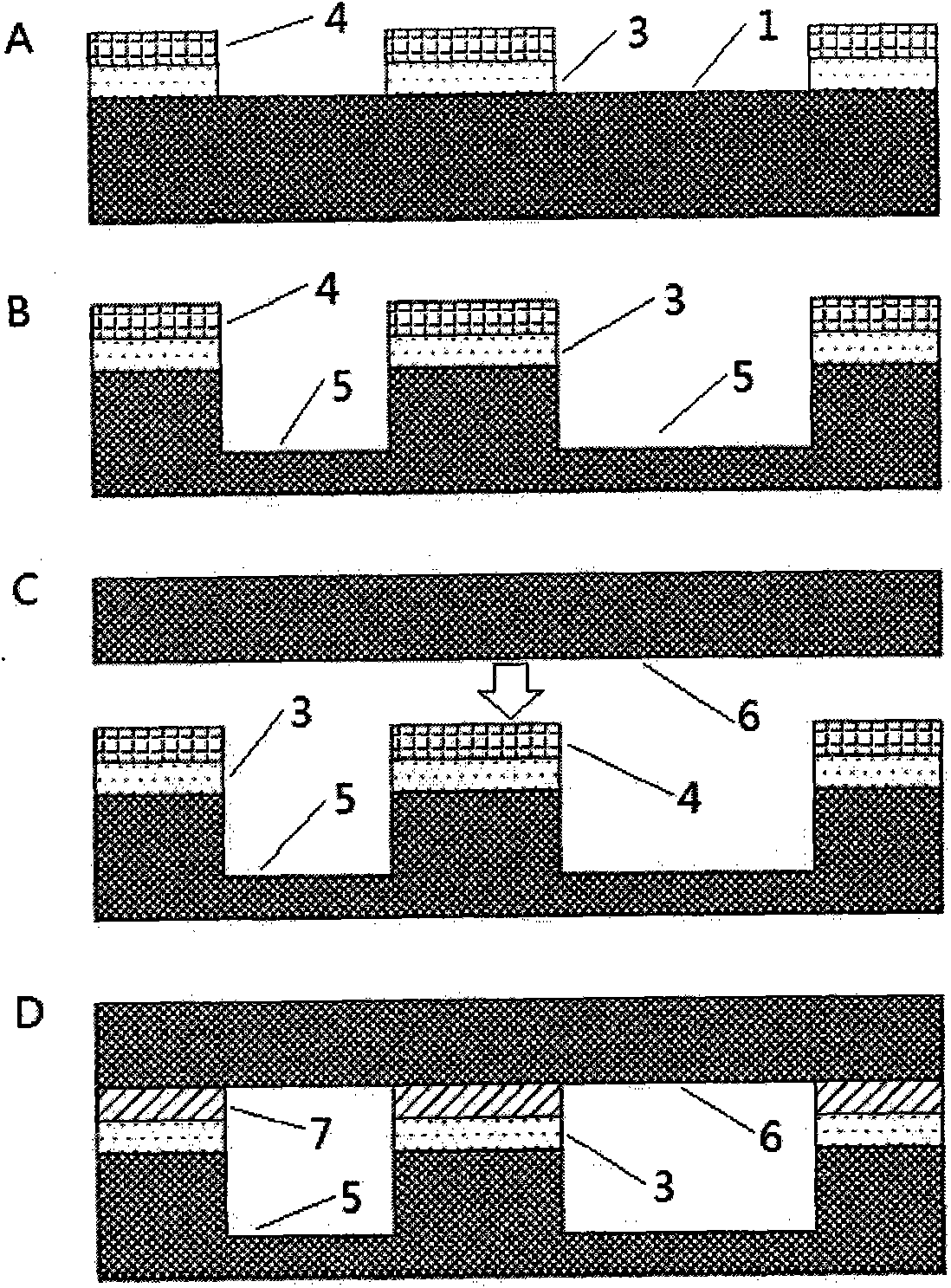

[0019] Embodiment 1 - micro gas enrichment device

[0020] The micro gas concentrator etches several parallel deep grooves with vertical side walls on the silicon wafer, and then bonds a top cover on the front of the silicon wafer to complete the sealing of the grooves. In this embodiment, the Ti / Au film mask is prepared by the lift-off method, the silicon deep groove is etched by the wet etching method, and the gold-silicon bonding is used to complete the sealing. The specific steps are as follows: figure 2 Shown:

[0021] A) First, use a coating machine to evenly coat a layer of photoresist 2 (AZ6112) on (110) the first silicon wafer 1, and then align the window opening direction of the pattern on the photolithographic plate with the first silicon wafer 1. That is, the {111} crystal orientation group is precisely aligned and then exposed and developed, and the pattern on the photoresist plate is transferred to the photoresist 2, and the cross-sectional morphology of the ph...

Embodiment 2

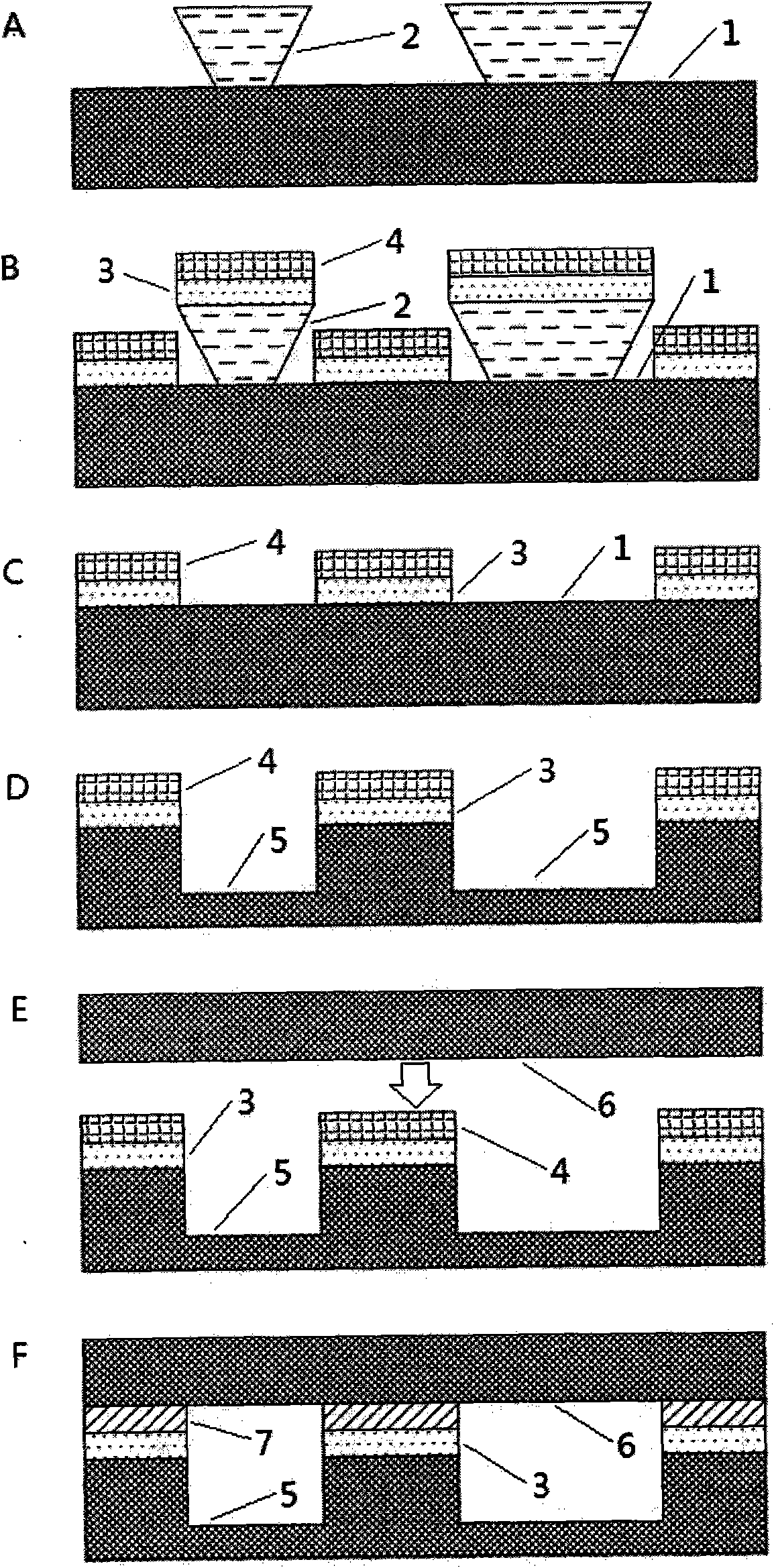

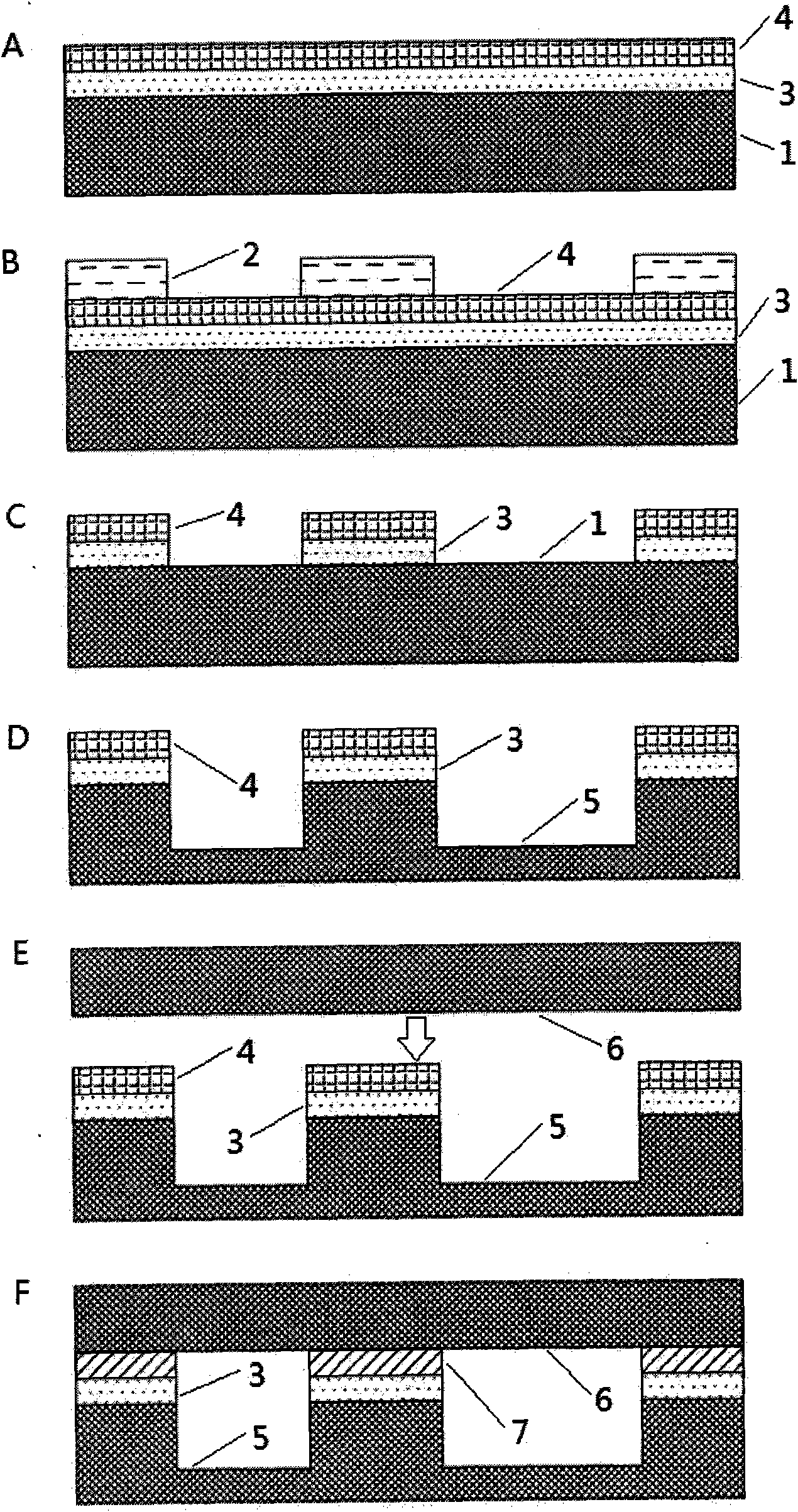

[0028] Embodiment 2-miniature gas chromatography column

[0029] The micro-gas chromatographic column is etched with a vertical deep groove on the silicon chip, and then a top cover is bonded on the front of the silicon chip to complete the sealing of the groove. The process flow of this embodiment is roughly as follows: first make a metal film layer, then perform photolithography and wet etching to form a metal mask, use dry etching to form a bulk silicon microstructure, and finally perform gold-silicon eutectic bonding. The specific steps Such as image 3 Shown:

[0030] A) On the cleaned first silicon wafer 1, a 50nm chromium film 3 and a 500nm gold film 4 are successively deposited by vacuum evaporation;

[0031] B) Exposure and development after spin-coating photoresist 2 to form a pattern;

[0032] C) using the photoresist 2 as an etching mask layer, corroding the gold film 4 and the chromium film 3 with a mixed solution of iodine+potassium iodide and tetraammonium ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com