Surface cleaning method of polished silicon substrate material

A technology of silicon substrate and back surface is applied in the field of surface cleaning after silicon substrate material polishing, which can solve the problems of high surface tension of polishing liquid, heavy metal pollution of silicon substrate, and high surface energy, so as to avoid particle scratches and achieve a perfect surface. Quality, the effect of improving perfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

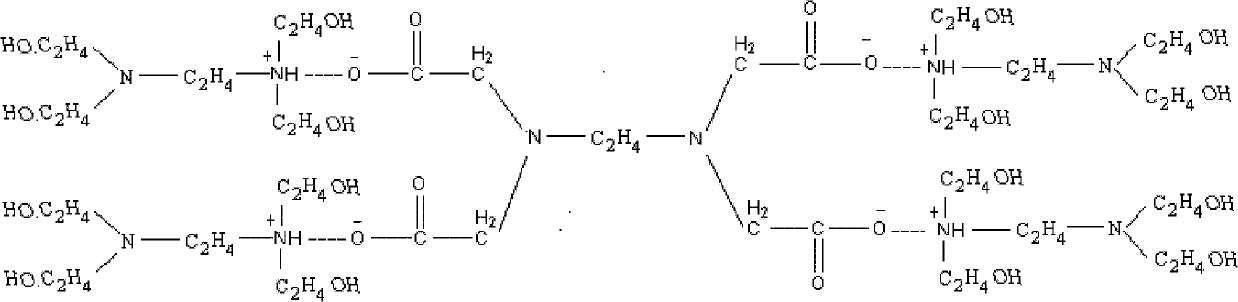

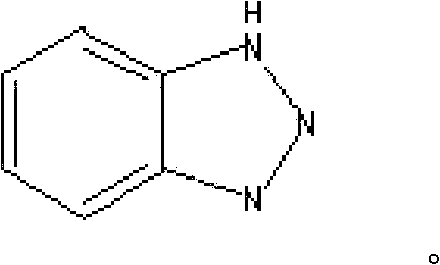

[0021] (1) Preparation of cleaning solution: parts by weight (parts)

[0022] Add 50g of FA / O surfactant, 75g of FA / OII type chelating agent, and 75g of FA / OII type composite corrosion inhibitor into 2300g of ultra-pure deionized water above 18MΩ, stir evenly while adding, and prepare 2500g of cleaning solution ;Use the prepared cleaning solution to polish and clean the silicon substrate material after alkaline chemical mechanical polishing at a low pressure below 3000Pa and a large flow rate of 4000ml / min, and the polishing and cleaning time is 2min, so that the surface of the silicon substrate material clean. The silicon substrate surface after cleaning has no corrosion patterns, and the surface roughness is Ra=0.3nm (10 μm×10 μm).

Embodiment 2

[0024] (1) Preparation of cleaning solution: parts by weight (parts)

[0025] Add 50g of FA / O surfactant, 10g of FA / OII type chelating agent, and 20g of FA / OII type composite corrosion inhibitor into 2200g of ultra-pure deionized water above 18MΩ, stir evenly while adding, and prepare 3000g of cleaning solution ;Use the prepared cleaning solution to polish and clean the silicon substrate material after alkaline chemical mechanical polishing at a low pressure below 1000Pa and a large flow rate of 5000ml / min, and the polishing and cleaning time is 1min, so that the surface of the silicon substrate material clean. The silicon substrate surface after cleaning has no corrosion patterns, and the surface roughness is Ra=0.2nm (10 μm×10 μm).

[0026] The role of the technology used is: after the silicon substrate material is alkaline polished, there are problems such as high energy, high surface tension, uneven distribution of residual polishing liquid, and contamination of metal ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com