Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

A technology of ceramic particles and composite materials, applied in the field of composite wear-resistant pipes, can solve the problems of poor corrosion resistance of thermosetting plastics, low bonding force between plastics and steel pipes, easy deformation and falling off, etc., to achieve wear resistance and corrosion resistance. The effect of improved performance, simple manufacturing process, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

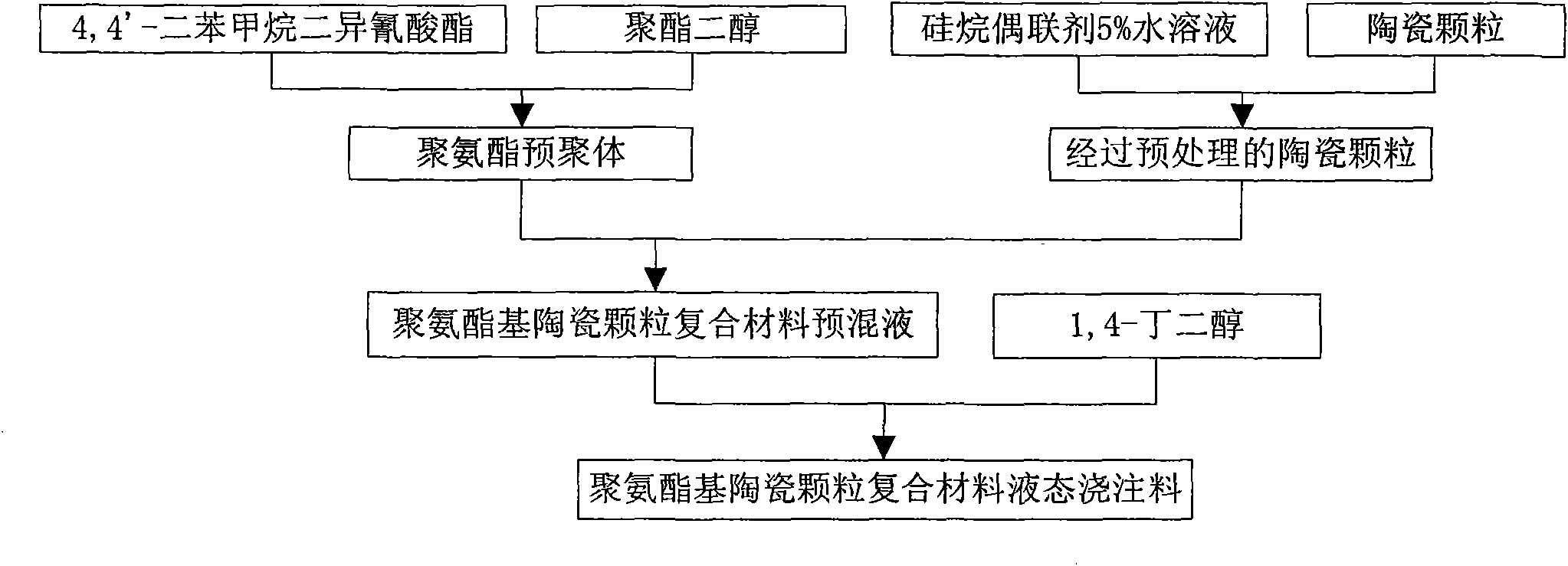

[0040] Refer to attached figure 1 , weigh 50 kg of 180-mesh industrial alumina particles, immerse in an aqueous solution containing KH-550 silane coupling agent with a mass fraction of 5%, stir for 1 hour, filter and dry; 1000 parts of 4,4'-diphenyl A mixture of methane diisocyanate (MDI) and 500 parts of polyester diol as a polyurethane prepolymer, mixed with the above-mentioned pretreated alumina particles, stirred for 2 hours and then added 80 parts of 1,4-butanediol (BD) , after uniform stirring, the polyurethane liquid castable is obtained.

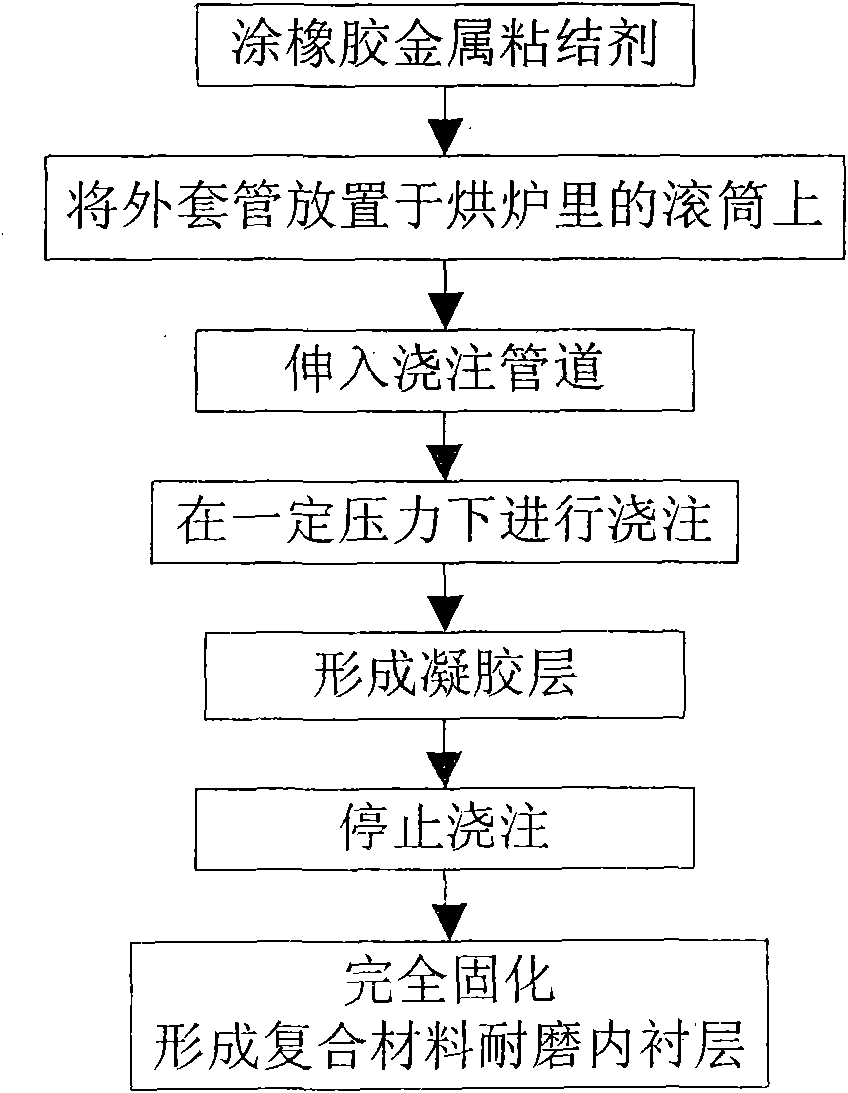

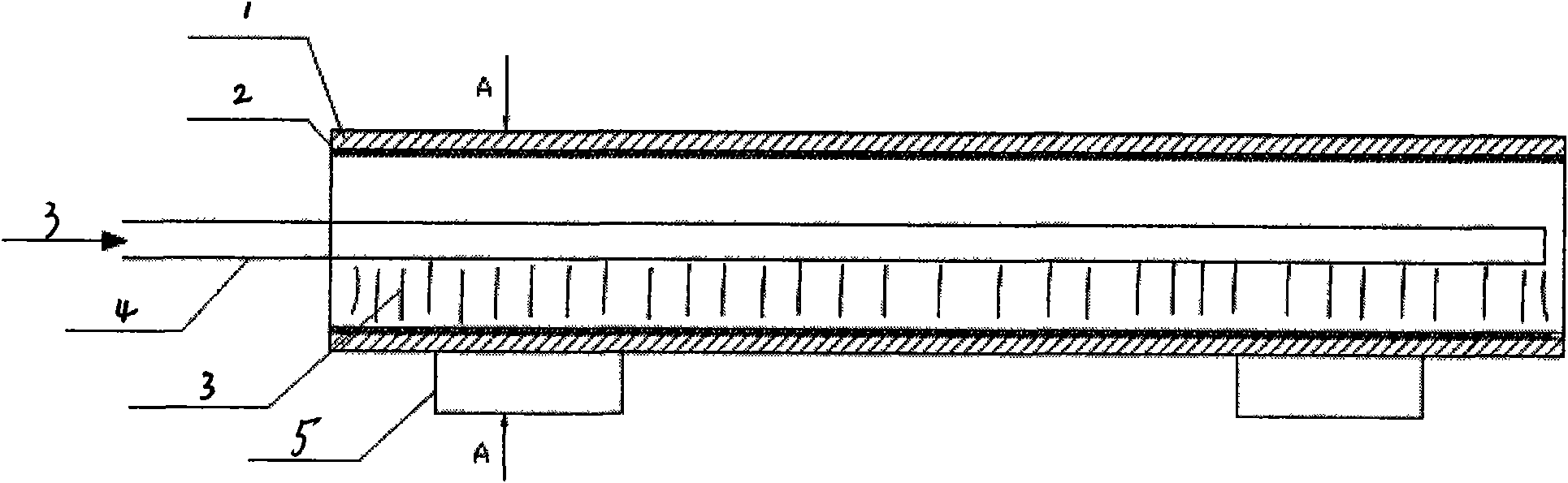

[0041] refer to figure 2 , image 3 and Figure 4 , the manufacture of composite material-lined metal pipes: first evenly paint a layer of rubber-metal adhesive on the inner wall of the stainless steel seamless steel pipe, that is, the outer casing 1, and then place it on four rollers 5 in a large oven, among which A drum rotates at 300 rpm. When the jacket steel pipe is heated to 90°C, keep the constant temperature, extend int...

Embodiment 2

[0044] Refer to attachedfigure 1 , weighing 100 kg of 300-mesh industrial quartz sand particles, immersed in an aqueous solution containing 5% KH-550 silane coupling agent, stirred for 1 hour, filtered and dried; 1000 parts of M5050 type Polyurethane prepolymer (the main component is 4,4'-diphenylmethane diisocyanate), mixed with the above-mentioned pretreated quartz sand particles, stirred for 1.5 hours and then added 50 parts of 1,4-butanediol (BD), After uniform stirring, the polyurethane liquid castable is prepared.

[0045] Coat the inner wall of stainless steel seamless steel pipe evenly with 218 type rubber metal adhesive from Chemlok, and then place it on four rollers in a large oven, one of which rotates at 500 rpm turn. When the jacket steel pipe is heated to 100°C, keep the temperature constant, extend into the pouring pipe with slots below, inject the liquid castable into the pouring pipe under a certain pressure, make the liquid castable squeeze out along the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com