Treatment method of storage tank-dissipating stinking sulfur-containing waste gas

A waste gas treatment and dissipation technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as danger and safety, failure to regenerate activated carbon, etc., to reduce operating costs, improve gas-liquid contact effect, and increase absorption rate and the effect of operational elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

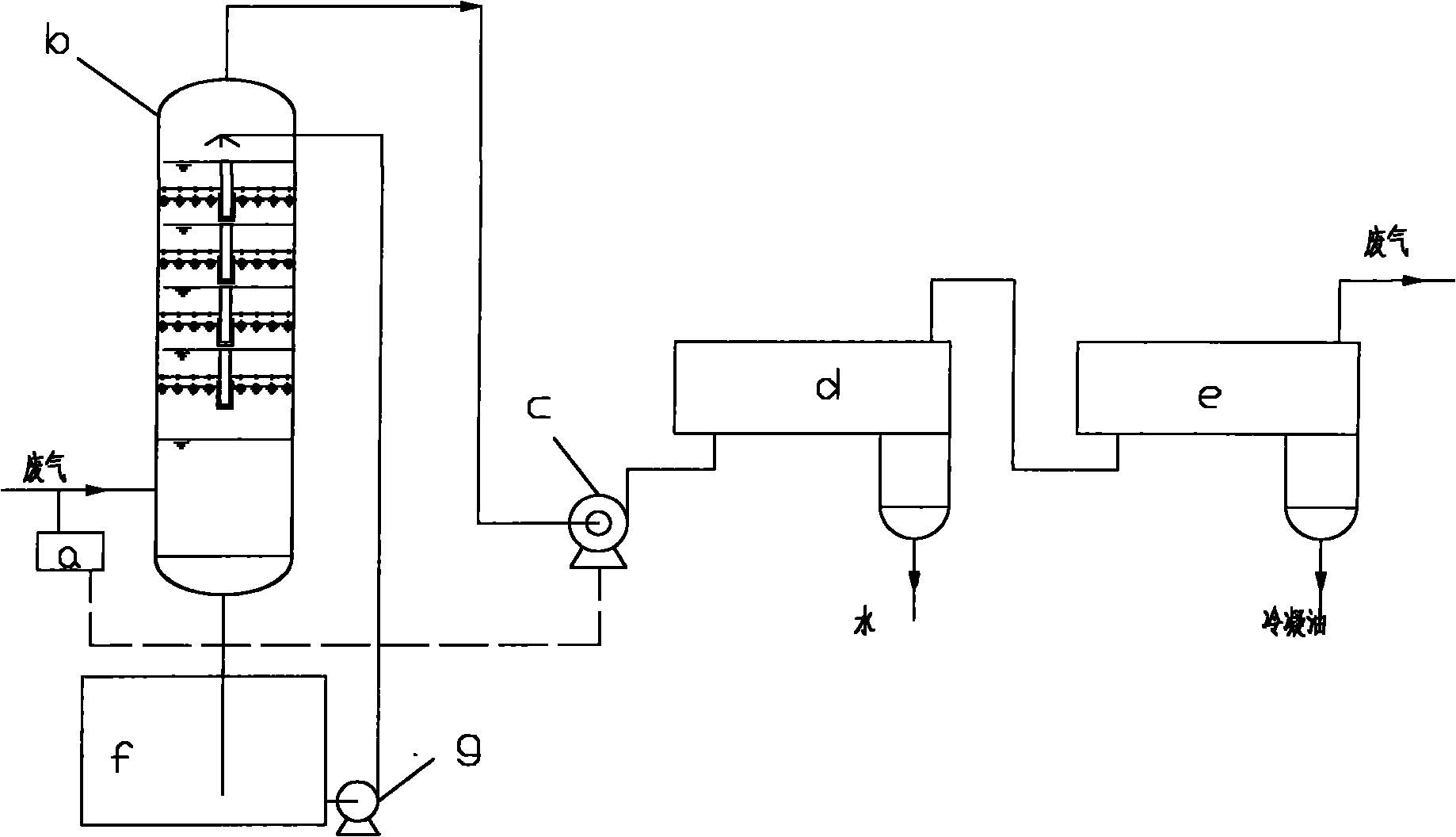

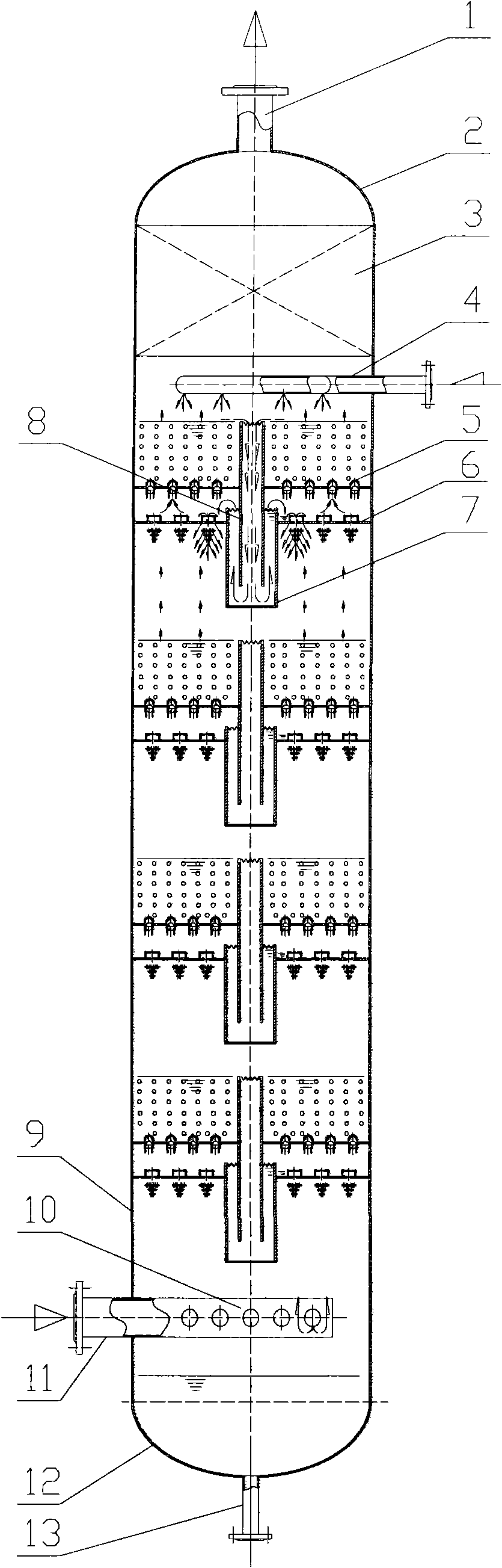

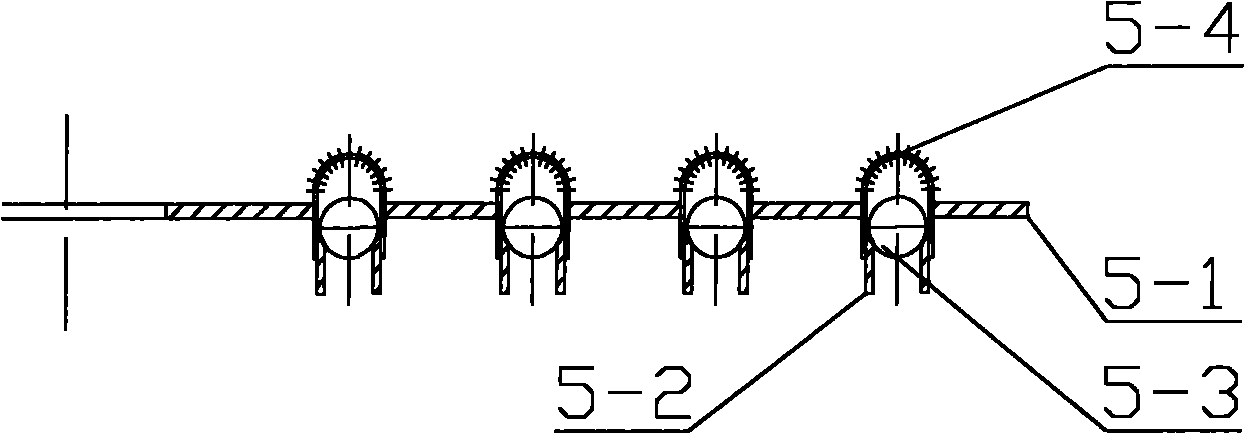

[0040] The breathing gas of an enterprise's waste oil tank contains hydrogen sulfide 1000mg / m 3 , containing hydrocarbons 20v% (volume fraction), the flow rate is 100Nm 3 / h or so. A three-stage pulse bubbling absorption tower is adopted, including three bubbling absorption zones and three spraying absorption zones, and the internal components of the absorption tower are determined according to the preferred data in the specific embodiment. The thickness of the liquid layer in the bubbling absorption zone is 350mm, and the height of the spray section is 250mm. The absorbent is 5% NaOH solution, the liquid-gas ratio is 100L / m 3 , operating temperature is 25°C. After the absorbed waste gas undergoes condensation dehydration and condensation recovery of hydrocarbons, the cooling temperature of the dehydration condenser is 2°C, and the condensation temperature of the hydrocarbon recovery condenser is -75°C, and a small amount of non-condensable gas is directly evacuated.

[00...

Embodiment 2

[0043] The breathing gas of a sulfur-containing sewage tank in an enterprise contains hydrogen sulfide 1000mg / m 3 , methyl mercaptan 200mg / m 3 , dimethyl disulfide 50mg / m 3 , hydrocarbon 10v%, flow rate is 150Nm 3 / h or so. A three-stage pulse bubbling absorption tower is adopted, including three bubbling absorption zones and three spraying absorption zones, and the internal components of the absorption tower are determined according to the preferred data in the specific embodiment. The thickness of the liquid layer in the bubbling absorption zone is 350mm, and the height of the spray section is 250mm. The absorbent is a solution containing 5% NaOH, 10% NaClO, and 5% cobalt sulfonated phthalocyanine, and the liquid-gas ratio is 50L / m 3 , operating temperature is 25°C. After the absorbed exhaust gas undergoes condensation dehydration and condensation recovery of hydrocarbons, the cooling temperature of the dehydration condenser is 2°C, the condensation temperature of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com