Zirconia-alumina composite oxide carrier and method for preparing same

A composite oxide and alumina support technology, which is applied in the direction of catalyst activation/preparation, catalyst support, chemical instruments and methods, etc., can solve the problems of restricted diffusion of macromolecular reactants or products, and achieve extended operation period and increased The effect of deposition amount and large orifice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

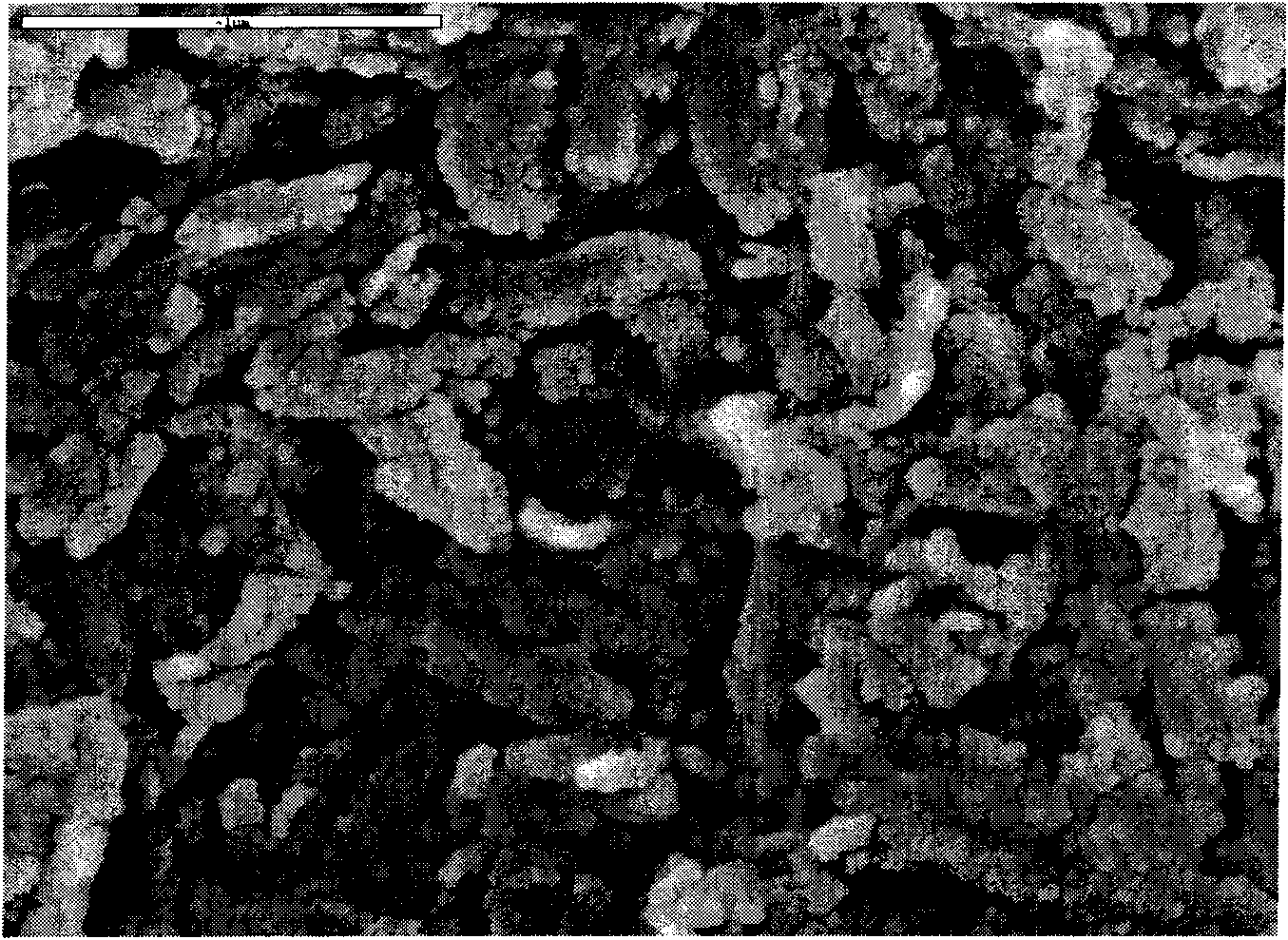

Image

Examples

Embodiment 1

[0046] Under stirring conditions, 750g of aluminum nitrate nonahydrate, 42g of zirconium oxychloride and 105g of urea were mixed and heated to 100°C, and added to the mixture of 80g of polyisobutylene triethanolamine maleate and 148g of 150HVI neutral oil at the same temperature , form a super solubilized micelle group, mix uniformly, and then react at 130° C. for 10 hours to obtain a nano zirconium hydroxide-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 8 hours. Mix 70 g of nano zirconium hydroxide-aluminum hydroxide gel dry powder and 30 g of pseudo-boehmite evenly. Mix 6g of dilute nitric acid (mass concentration 17%), 60g of water and 10g of ethanol evenly, then add to the mixture of nano zirconium hydroxide-aluminum hydroxide gel dry powder and binder, stir evenly, and mix on a mixer Uniform, and then shaped in the extruder, the pressure is controlled at 10MPa. The molded product was dried at 100°C for 10 hours, calcined at...

Embodiment 2

[0048]Under stirring conditions, 750g of aluminum nitrate nonahydrate, 322g of zirconium oxychloride, and 210g of urea were mixed and heated to 100°C, and added to the mixture of 80g of polyisobutylene triethanolamine maleate and 148g of 150HVI neutral oil at the same temperature , form a super solubilized micelle group, mix uniformly, and then react at 130° C. for 10 hours to obtain a nano zirconium hydroxide-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 8 hours. Mix 80 g of nano zirconium hydroxide-aluminum hydroxide gel dry powder and 20 g of pseudo-boehmite evenly. Mix 6g of hydrochloric acid, 60g of water and 10g of ethanol evenly, then add to the mixture of nano-zirconium hydroxide-aluminum hydroxide gel dry powder and binder, stir evenly, mix evenly on the mixer, and then put it on the extruder Molding in middle, control pressure at 10MPa. The molded product was dried at 100°C for 10 hours, calcined at 240°C for 3 hours, ...

Embodiment 3

[0050] Mix 110g of second-line dewaxed oil and 31g of SP-80, heat to dissolve at 90°C, and mix well; heat 750g of aluminum nitrate nonahydrate and 620g of zirconium oxychloride to 80°C to melt, slowly add to the above mixture, and mix for 20 minutes to form Uniform super solubilized colloid, mix well. 220 g of saturated ammonia water at 20° C. was added dropwise and aged for 3 hours to obtain a nano zirconium hydroxide-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours. Mix 138.8g of nano zirconium hydroxide-aluminum hydroxide gel dry powder with 92.5g of pseudoboehmite; 2.31g of acetic acid, 189g of water and 2.31g of cosolvent methanol are mixed evenly, and are mixed evenly on a mixer, and then Molded in extruder, control pressure at 30MPa. The molded product was dried at 130°C for 30 hours, calcined at 240°C for 10 hours, and calcined at 850°C for 4 hours, wherein the heating rate was 5°C / min to obtain the zirconia-alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com