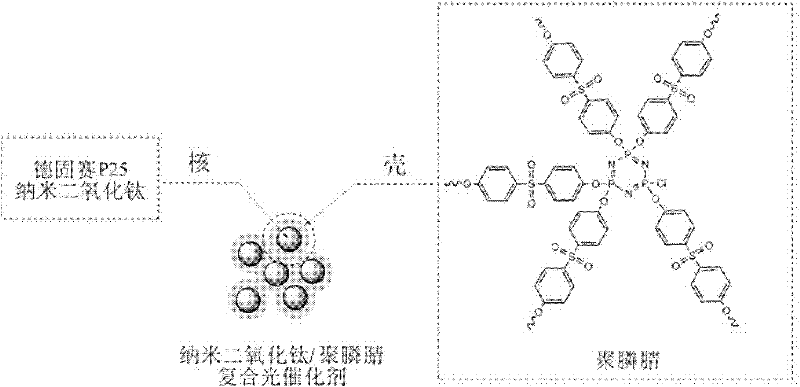

Nano-titanium dioxide and polyphosphazene based composite optical catalyst and preparation method thereof

A nano-titanium dioxide, polyphosphazene technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Weak load fastness and other problems, to achieve the effects of high specific surface and adsorption capacity, efficient and stable recycling, and simple and effective preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

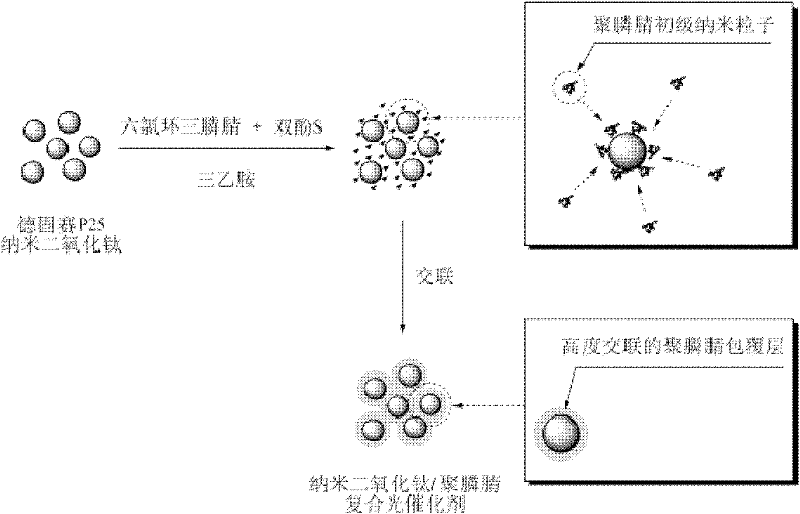

[0027] In a 100mL round bottom flask, disperse 0.02g of hexachlorocyclotriphosphazene, 0.0432g of bisphenol S and 0.05g of Degussa P25 nano-titanium dioxide in a mixed solvent of 60mL of tetrahydrofuran and absolute ethanol (volume ratio of 1:1 ), ultrasonic treatment for 30 minutes to make the dispersion uniform. Then, 2 mL of triethylamine was added to the above dispersion, and reacted in a 40°C, 100W ultrasonic water bath for 5 hours. After the reaction, the target product was centrifuged at a speed of 3500 rpm, and the solvent was removed after separation for 15 minutes. The product was washed three times with acetone and deionized water respectively, and then dried in an oven at 80°C for 10 hours to obtain a white powder composite photocatalyst based on nano-titanium dioxide and polyphosphazene.

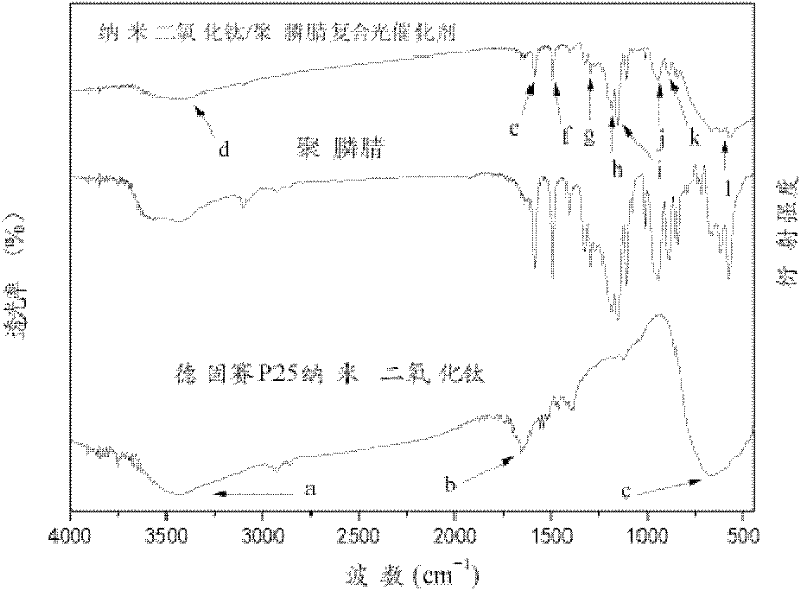

[0028] Implementation effect of this embodiment: image 3 The Fourier transform infrared spectrum of the prepared composite photocatalyst based on nano-titanium dioxide and po...

Embodiment 2

[0033] In a 100mL round bottom flask, disperse 0.02g of hexachlorocyclotriphosphazene, 0.0432g of bisphenol S and 0.03g of Degussa P25 nano-titanium dioxide in a mixed solvent of 60mL of tetrahydrofuran and absolute ethanol (volume ratio of 1:1 ), ultrasonic treatment for 30 minutes to make the dispersion uniform. Then, 2 mL of triethylamine was added to the above dispersion, and reacted in a 40°C, 100W ultrasonic water bath for 5 hours. After the reaction, the target product was centrifuged at a speed of 3500 rpm, and the solvent was removed after separation for 15 minutes. The product was washed three times with acetone and deionized water respectively, and then dried in an oven at 80°C for 10 hours to obtain a white powder composite photocatalyst based on nano-titanium dioxide and polyphosphazene.

[0034] Such as Figure 6 Shown are the scanning electron micrographs and transmission electron micrographs of the prepared composite photocatalyst based on nano-titanium dioxi...

Embodiment 3

[0036] In a 100mL round bottom flask, disperse 0.02g of hexachlorocyclotriphosphazene, 0.0432g of bisphenol S and 0.09g of Degussa P25 nano-titanium dioxide in a mixed solvent of 60mL of tetrahydrofuran and absolute ethanol (volume ratio of 1:1 ), ultrasonic treatment for 30 minutes to make the dispersion uniform. Then, 2 mL of triethylamine was added to the above dispersion, and reacted in a 40°C, 100W ultrasonic water bath for 5 hours. After the reaction, the target product was centrifuged at a speed of 3500 rpm, and the solvent was removed after separation for 15 minutes. The product was washed three times with acetone and deionized water respectively, and then dried in an oven at 80°C for 10 hours to obtain a white powder composite photocatalyst based on nano-titanium dioxide and polyphosphazene.

[0037] Such as Figure 7 Shown are the scanning electron micrographs and transmission electron micrographs of the prepared composite photocatalyst based on nano-titanium dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com