Method for preparing novel cefixime tablets and cefixime capsules

A technology of cefixime and capsules, which is applied in the field of pharmaceutical preparations, can solve the problems of cumbersome granulation process, small amount of excipients, and unsatisfactory dissolution rate of tablets, etc., achieve rapid blood drug concentration, increase dissolution rate, and avoid related substances Elevated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the preparation of cefixime capsule

[0017] Preparation prescription of the present invention is made up of following components by weight:

[0018] Cefixime 50g

[0019] Sodium Lauryl Sulfate 4g

[0020] Lactose 60g

[0021] Microcrystalline Cellulose 30g

[0022] Croscarmellose Sodium 15g

[0024]

[0025] Make 1000 capsules

[0026] Preparation process: Weigh cefixime, sodium lauryl sulfate and lactose according to the above prescription, and carry out jet milling. Weigh microcrystalline cellulose and croscarmellose sodium according to the prescription amount, crush them and pass through an 80-mesh sieve, mix them evenly with the above air-pulverized materials, granulate them in a dry granulator, add magnesium stearate and mix them evenly before filling capsule.

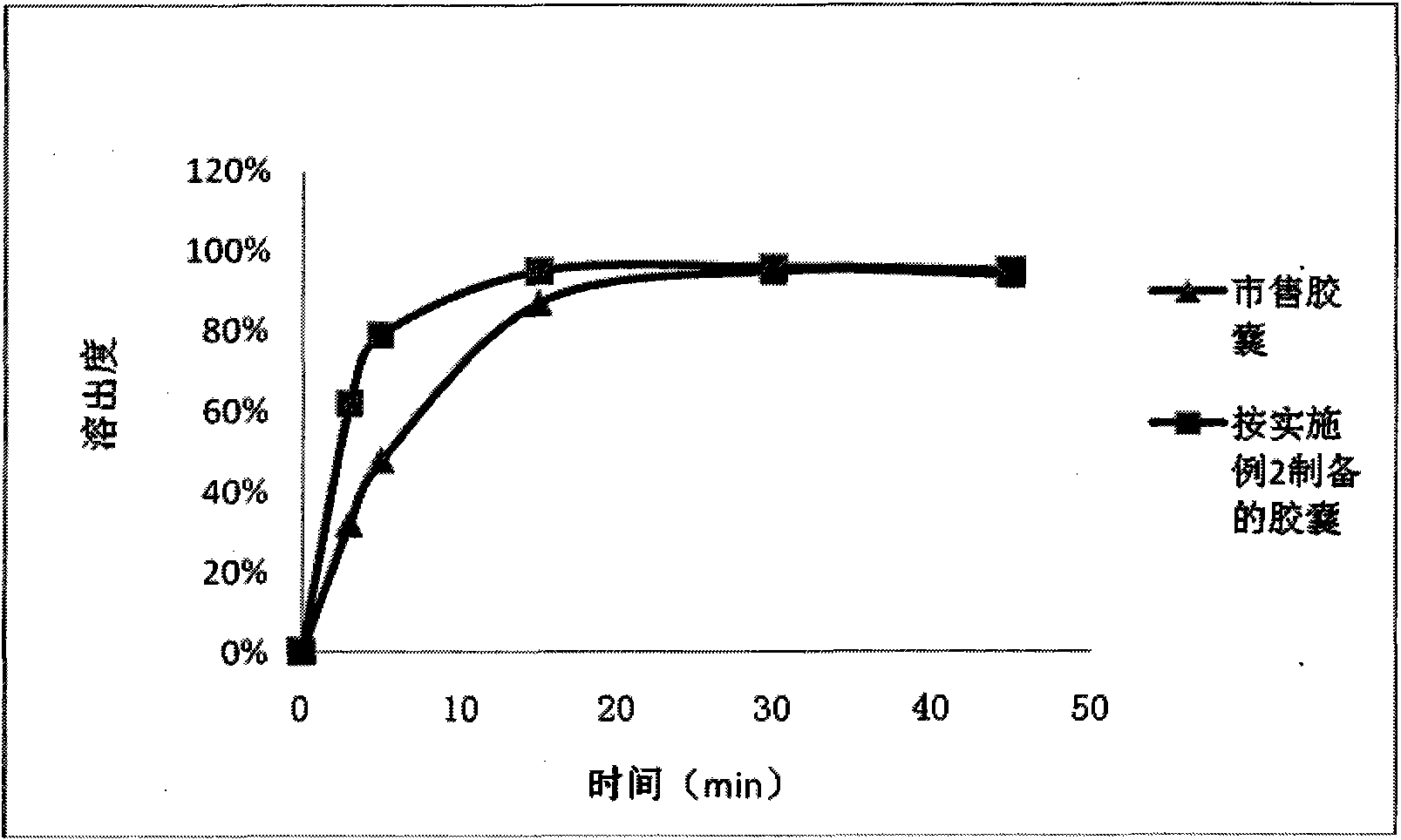

Embodiment 2

[0027] Embodiment 2: the preparation of cefixime capsule

[0028] Preparation prescription of the present invention is made up of following components by weight:

[0029] Cefixime 100g

[0030] Sodium Lauryl Sulfate 4g

[0031] Lactose 30g

[0032] 20g pregelatinized starch

[0033] Croscarmellose Sodium 15g

[0035]

[0036] Make 1000 capsules

[0037] Preparation Process:

[0038] Weigh cefixime, sodium lauryl sulfate and lactose respectively according to the above prescription, and carry out jet milling. Weigh pregelatinized starch and croscarmellose sodium according to the prescription amount, crush them and pass through an 80-mesh sieve, mix them evenly with the above-mentioned air-pulverized materials, granulate them in a dry granulator, add magnesium stearate and mix them evenly before filling capsule.

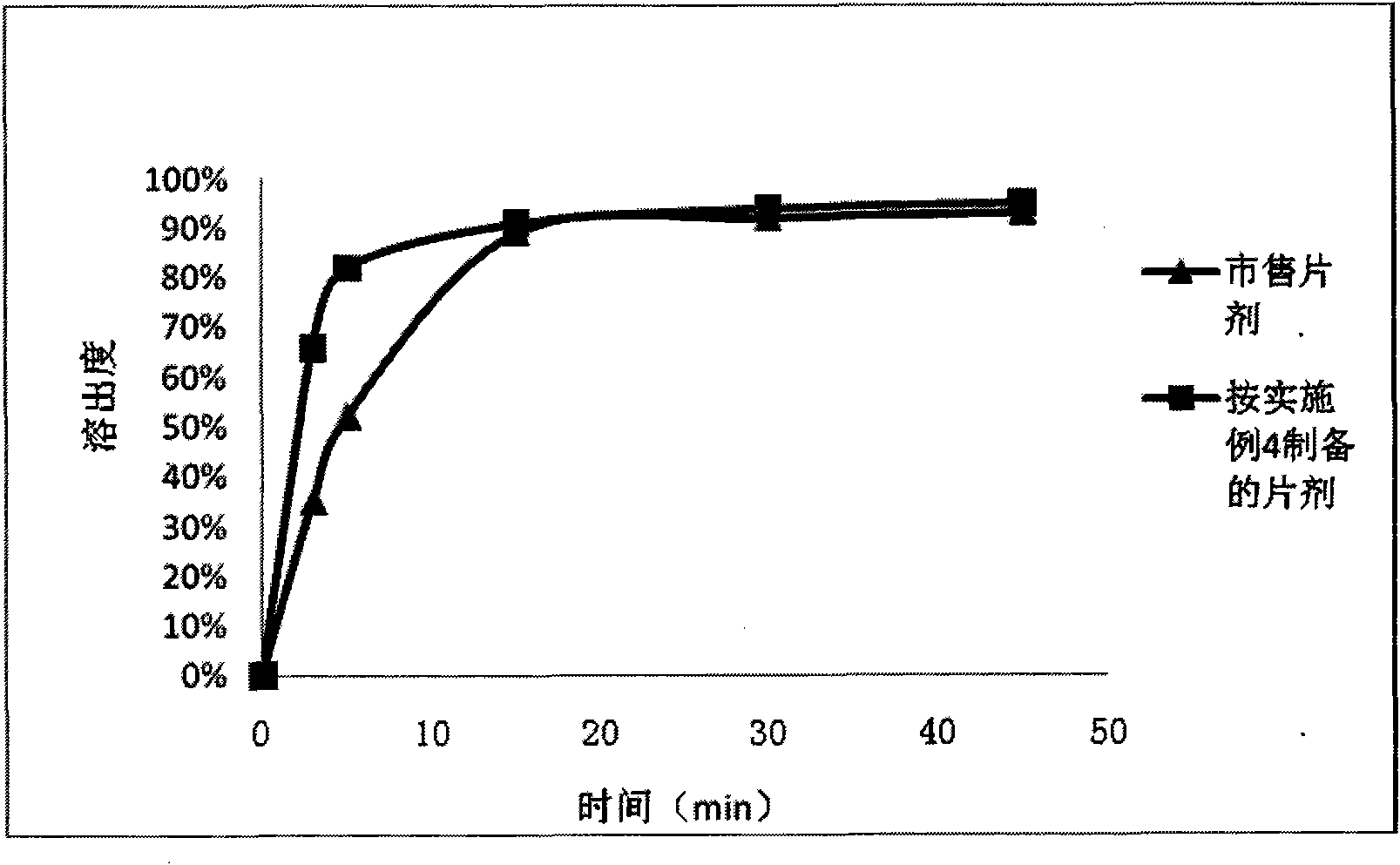

Embodiment 3

[0039] Embodiment 3: the preparation of cefixime tablet

[0040] Preparation prescription of the present invention is made up of following components by weight:

[0041] Cefixime 50g

[0042] Sodium Lauryl Sulfate 4g

[0043] Lactose 60g

[0044] Microcrystalline Cellulose 30g

[0045] Croscarmellose Sodium 20g

[0047]

[0048] Made into 1000 pieces

[0049] Preparation Process:

[0050] Weigh cefixime, sodium lauryl sulfate and lactose respectively according to the above prescription, and carry out jet milling. Weigh microcrystalline cellulose and croscarmellose sodium according to the prescription amount, pass through an 80-mesh sieve after crushing, mix evenly with the above-mentioned air-pulverized material, granulate with a dry granulator, add magnesium stearate and mix evenly, and press piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com