Bacterial strain tolerant with various inhibitors of Saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and inhibitor, applied in the field of Saccharomyces cerevisiae, can solve the problems affecting the ethanol fermentation yield and rate of cellulose hydrolyzate, and achieve the effect of high-efficiency ethanol production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

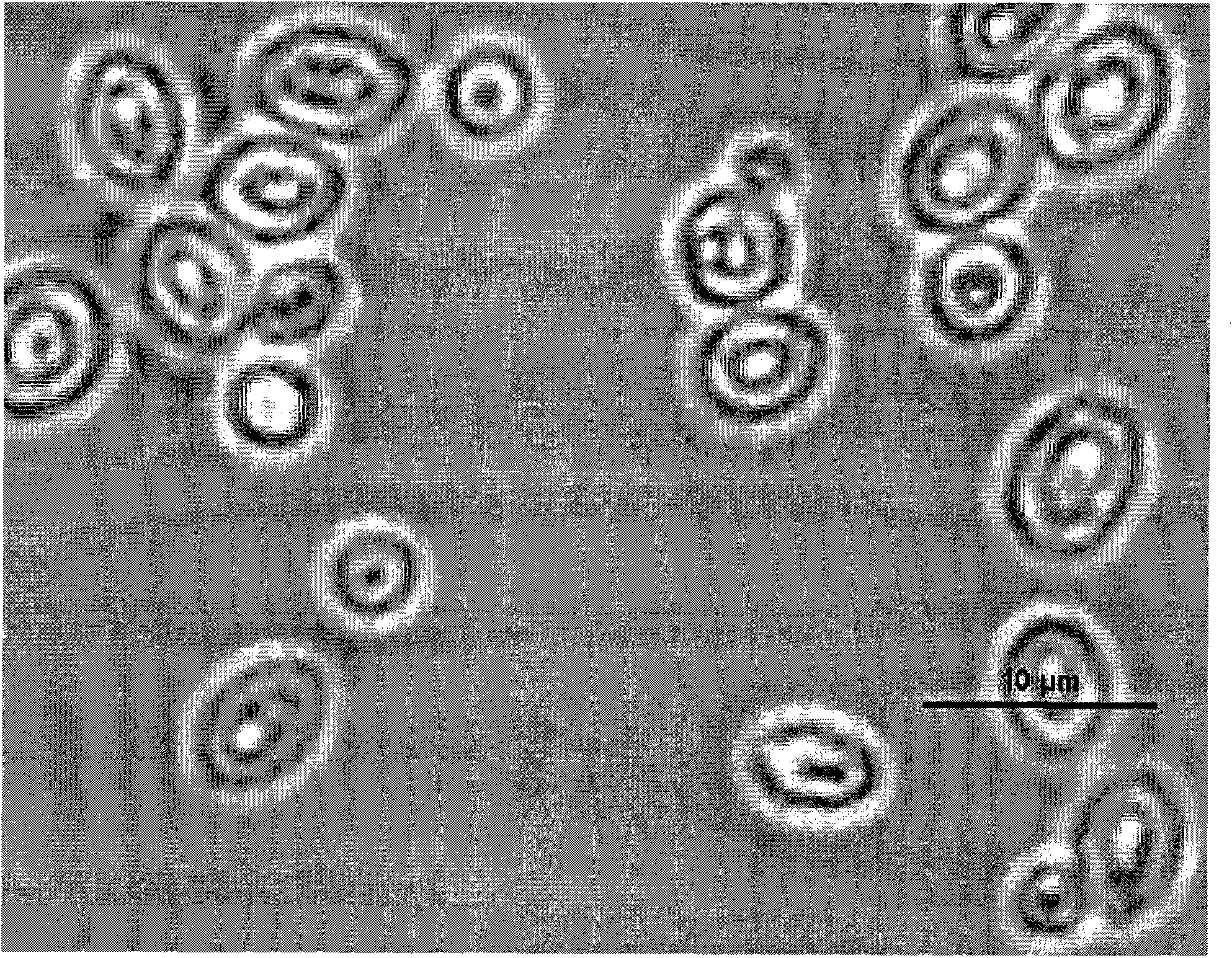

[0022] Isolation of YYJ003 strain

[0023] A novel strain YYJ003 of Saccharomyces cerevisiae tolerant to various inhibitors of the present invention is obtained by carrying out ultraviolet mutagenesis to industrial Saccharomyces cerevisiae through tolerance and domestication of various inhibitors. The ultraviolet mutagenesis strategy is: the culture solution of the original S strain (YEPD medium: glucose 20g / L, yeast powder 10g / L, peptone 20g / L) is diluted and spread on the screening medium containing inhibitors (adding inhibitors YEPD medium), irradiate the paved plate at a distance of 30cm from a 15W ultraviolet lamp for 60 seconds, and place it in a 30°C incubator for 3 days in the dark. The strain acclimation step is as follows: the colonies grown on the selection medium are transferred to the liquid selection selection medium containing inhibitors for cultivation, and the cultivation conditions are 30° C., 180 rpm. When cultured to the stationary phase, according to OD ...

Embodiment 2

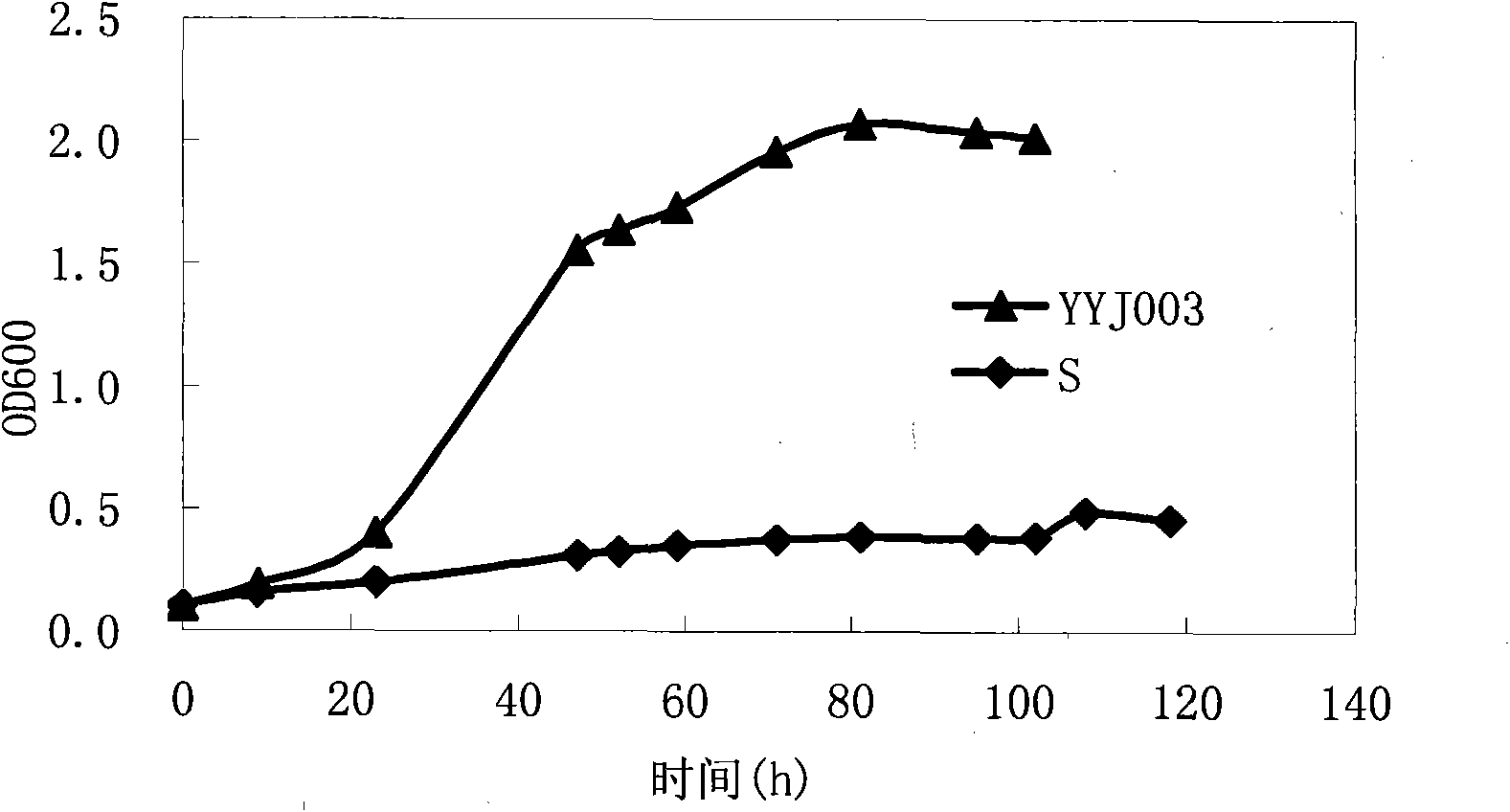

[0025] Comparison of the growth of the YYJ003 strain with the original strain on shake flasks

[0026] 1. Test materials: The strain YYJ003 was screened by our laboratory and preserved in the General Microbiology Center of China Microbiological Culture Collection Management Committee, with the preservation number CGMCC NO.2757; the original strain Saccharomyces cerevisiae was purchased from Hubei Angel Yeast Co., Ltd., referred to as S strain.

[0027] 2. Test method:

[0028] Seed medium:

[0029] YYJ003 strain: glucose 20g / L, yeast powder 10g / L, peptone 20g / L, furfural 1.3g / L, phenol 0.5g / L, acetic acid 5.3g / L, sterilized at 121°C for 20min. Original strain: glucose 20g / L, yeast powder 10g / L, peptone 20g / L, sterilized at 121°C for 20min.

[0030] Fermentation medium:

[0031] Glucose 20g / L, yeast powder 10g / L, peptone 20g / L, sterilized at 121°C for 20min. Before fermentation, inhibitors were added to make the final concentration of furfural 1.3g / L, phenol 0.5g / L, and ace...

Embodiment 3

[0038] Comparing the fermentation performance of YYJ003 strain and the original strain in 2% glucose medium fermenter

[0039] 1. Test material: same as Example 2.

[0040] 2. Test method:

[0041] The preparation of seeds and fermentation medium is the same as in Example 2.

[0042] The YYJ003 strain and the original strain were inoculated in 100mL seed medium respectively, and cultured at 30°C and 180rpm for 12-14h, both at the initial cell concentration OD 600 =0.1 was inoculated in a 5L fermentation tube with 3L fermentation medium, cultured at 30°C and 300rpm, and the growth curve, glucose concentration, ethanol concentration and furfural concentration were measured.

[0043] 3. Analysis method:

[0044] The cell concentration was characterized by measuring the absorbance value at 600 nm with a 722-type spectrophotometer. Glucose concentration and ethanol concentration were measured by high performance liquid chromatography (Waters1515), the chromatographic column was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com