Method for preparing crystal silicon wafer cutting edge material

A cutting edge, crystalline silicon wafer technology, applied in the field of cutting and grinding materials, can solve the problems of low output, high water consumption, long pickling time, etc. Strong abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

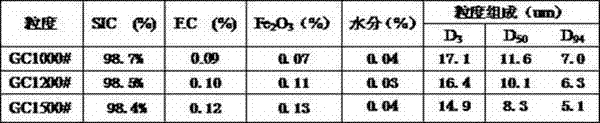

Embodiment 1

[0027] Embodiment 1 A kind of preparation method of crystalline silicon wafer cutting blade comprises the following steps:

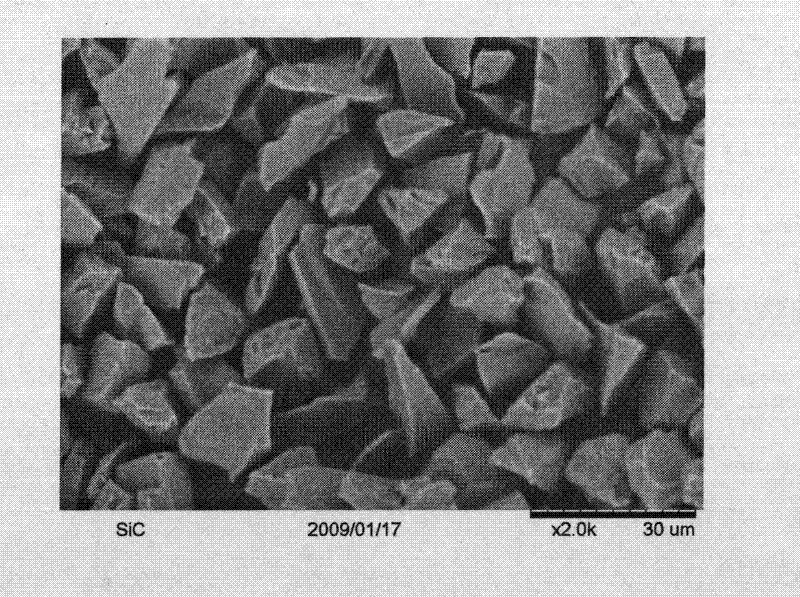

[0028] (1) Crushing of raw materials: select green silicon carbide block materials with a purity ≥ 98%, carry out jaw crushing and sieving, and collect silicon carbide particle size sand with a particle size ≤ 5mm;

[0029] (2) Dry ball mill classification: When using dry ball mill classifiers to grind the above-mentioned silicon carbide particle size sand, the amount of steel balls added is 400kg, the ball-to-material ratio is 3:1, the mill speed is 120rpm, and the primary airflow The speed of the classifier is 800rpm to obtain the main product (silicon carbide powder with a required particle size range of 4.5-18um), the speed of the secondary air classifier is 1800rpm to obtain by-products, and the air intake of the induced draft fan is 3000m 3 / h. Control the air intake of the induced draft fan, so that the fine powder that meets the particle size re...

Embodiment 2

[0037] Embodiment 2 A method for preparing a crystalline silicon wafer cutting blade, comprising the following steps:

[0038] (1) Crushing of raw materials: select green silicon carbide block materials with a purity ≥ 98%, carry out jaw crushing and sieving, and collect silicon carbide particle size sand with a particle size ≤ 5mm;

[0039](2) Dry ball mill classification: when using dry ball mill classification equipment, the amount of steel balls added is 500 kg, the ball-to-material ratio is 4:1, the mill speed is 180 rpm, and the speed of the first-stage air classifier is 850 rpm. 4.5 ~ 18um silicon carbide powder, the speed of the secondary air classifier is 2000rpm, to obtain by-products, the air intake of the induced draft fan is 3500m 3 / h.

[0040] (3) Pickling: Introduce the silicon carbide powder and water obtained in the previous step into the pickling tank, the weight ratio is 1:4, then add sulfuric acid according to 8% of the mass of the silicon carbide powder,...

Embodiment 3

[0047] Embodiment 3 A method for preparing a crystalline silicon wafer cutting blade, comprising the following steps:

[0048] (1) Raw material crushing: select green silicon carbide block materials with a purity ≥ 98%, carry out jaw crushing and sieving, and collect silicon carbide particle size sand with a particle size ≤ 5mm;

[0049] (2) Dry ball mill classification: When using dry ball mill classification equipment, the amount of steel balls added is 500 kg, the ball-to-material ratio is 3:1, the mill speed is 200 rpm, and the speed of the first-stage air classifier is 900 rpm. 4.5 ~ 18um silicon carbide powder, the speed of the secondary air classifier is 1900rpm, to obtain by-products, the air intake of the induced draft fan is 4000m 3 / h.

[0050] (3) Pickling: Add primary product and water in the pickling tank, the weight ratio is 1:2.5, then add sulfuric acid according to 8% of the mass of silicon carbide powder, stir and react for 6 hours, and then vacuum filter wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com