High solid content water-based damping paint and preparation method thereof

A technology of damping coating and high solid content, applied in the direction of coating, etc., can solve the problems that affect the actual use of water-based damping coating, narrow damping temperature range, easy deformation of coating film, etc., achieve good market promotion prospects, improve damping performance and elasticity Effect of low modulus and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

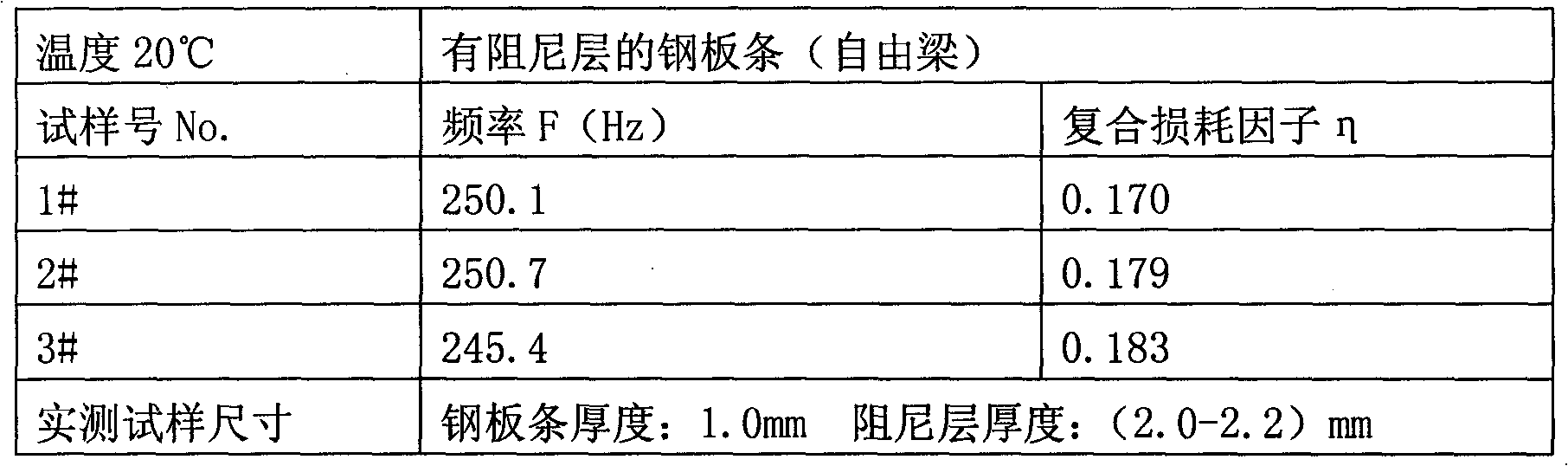

Embodiment 1

[0018] In the high-solid content water-based damping coating of this embodiment, the main components are proportioned according to the following weight ratios: 40 parts of water-based emulsion; 30 parts of flaky mica powder with a particle size of 80 mesh; 5 parts of rubber powder; 5 parts of liquid environmental protection flame retardant; 8 parts diester coalescent.

[0019] The method for preparing the high solid content water-based damping coating of the present embodiment may further comprise the steps:

[0020] (1) Preparation of water-based emulsion:

[0021] At room temperature, 30 parts of water-based acrylic emulsion with core-shell structure and 10 parts of network interpenetrating emulsion were uniformly mixed so that the solid content in the aqueous solution was 40%, and the water-based emulsion was obtained after stirring and mixing uniformly;

[0022] (2) Addition of fillers and additives:

[0023] Add flaky mica powder, rubber powder, and liquid environmental...

Embodiment 2

[0027] In the high-solid content water-based damping coating of this embodiment, the main components are proportioned according to the following weight ratios: 45 parts of water-based emulsion; 30 parts of flaky mica powder with a particle size of 120 mesh; 5 parts of rubber powder; 8 parts of liquid environmental protection flame retardant; 12 parts diester coalescent.

[0028] The method for preparing the high solid content water-based damping coating of the present embodiment may further comprise the steps:

[0029] (1) Preparation of water-based emulsion:

[0030] At room temperature, uniformly mix 30 parts of water-based acrylic emulsion with core-shell structure and 15 parts of network interpenetrating emulsion so that the solid content in the aqueous solution is 45%, and stir and mix uniformly to obtain the water-based emulsion;

[0031] (2) Addition of fillers and additives:

[0032] Add flaky mica powder, rubber powder, and liquid environmental protection flame reta...

Embodiment 3

[0036] In the high-solid content water-based damping coating of this embodiment, the main components are proportioned according to the following weight ratios: 50 parts of water-based emulsion; 30 parts of flaky mica powder with a particle size of 180 mesh; 6 parts of rubber powder; 12 parts of liquid environmental protection flame retardant; 15 parts diester coalescent.

[0037] The method for preparing the high solid content water-based damping coating of the present embodiment may further comprise the steps:

[0038] (1) Preparation of water-based emulsion:

[0039] At room temperature, 30 parts of water-based acrylic emulsion with core-shell structure and 20 parts of network interpenetrating emulsion were uniformly mixed so that the solid content in the aqueous solution was 50%, and the water-based emulsion was obtained after stirring and mixing uniformly;

[0040] (2) Addition of fillers and additives:

[0041] Add flaky mica powder, rubber powder, and liquid environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com