Reinforcing heat transfer method and heat exchange coil tube component for evaporative heat exchanger

A technology for strengthening heat transfer and heat exchange coils, which can be applied to tubular elements, heat exchange equipment, lighting and heating equipment, etc., and can solve the problems of low gas cooling heat transfer coefficient, increase in cost, height of the whole machine and increase in manufacturing cost. , to achieve the effect of reducing contact thermal resistance, saving space, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

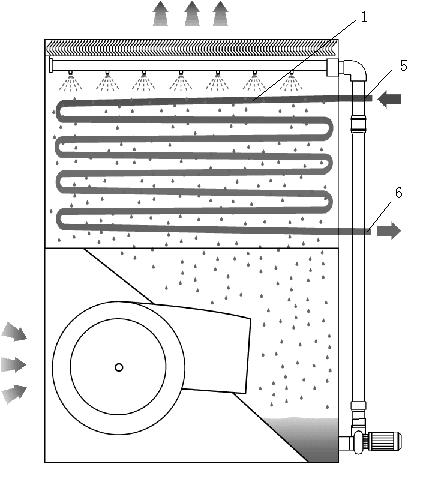

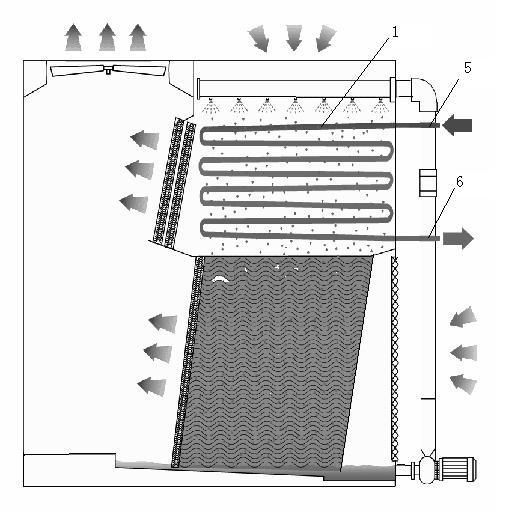

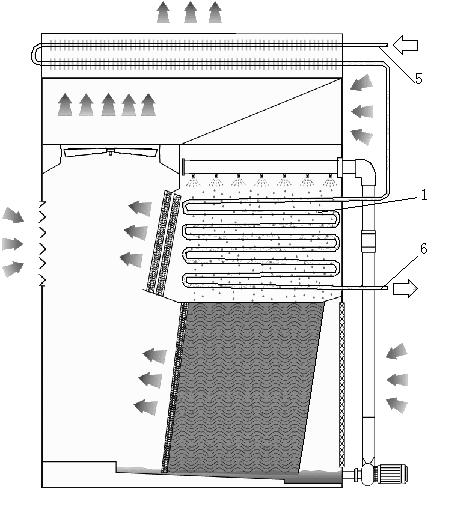

[0020] Example 1 : A refrigeration system using ammonia refrigerant, the condensation temperature is 35.7°C, the superheat of the ammonia vapor at the outlet of the compressor is 40°C, and the evaporative condenser adopts figure 2 Structure, upper coil and lower packing form, heat exchange coil assembly is composed of coil tube bundle 1, partition plate 2 arranged by tube bundle, spacer tube 3, tube bundle header 4, inlet 5 and outlet 6 connecting pipes, and other supporting parts , a total of 10 tube passes, the heat exchange area of the outer surface of the coil is 250m 2 , the proportion of convective heat transfer heat resistance in the superheated tube accounts for 75%.

[0021] The heat transfer effect is enhanced by installing enhanced heat transfer components in the coil tube bundles of some tube passes (the first and second tube passes at the entrance of the coil). Specifically, the coils used in the first and second tubes at the coil inlet are as follows: Fig...

Embodiment 2

[0023] Example 2 : Refrigeration system using freon (R22a) refrigerant, the steam superheat at the outlet of the compressor is 30°C, the condensation temperature is 40°C, and the evaporative condenser adopts figure 2 Structure, upper coil and lower packing form, heat exchange coil assembly is composed of coil tube bundle 1, partition plate 2 arranged by tube bundle, spacer tube 3, tube bundle header 4, inlet 5 and outlet 6 connecting pipes, and other supporting parts , a total of 10 tube passes, the heat exchange area of the outer surface of the coil is 250m 2 , the proportion of convective heat transfer heat resistance in the superheated tube accounts for 70%.

[0024] The heat transfer effect is enhanced by installing enhanced heat transfer components in the coil tube bundles of some tube passes (the first and second tube passes at the entrance of the coil). Specifically, the coils used in the first and second tubes at the coil inlet are as follows: Figure 4 , 5 As ...

Embodiment 3

[0026] Example 3 : Compressor outlet air cooler, using figure 1 Full-coil evaporative cooling heater, the heat exchange coil assembly is composed of coil tube bundle 1, partition board 2 arranged by tube bundle, spacer tube 3, tube bundle header 4, inlet 5 and outlet 6, and other supporting parts , The coil structure is a U-shaped structure with 2 tubes, 8 loops, and the tube length is 3.5m.

[0027] The enhanced heat transfer components are installed in the coil tube bundles of all tubes to enhance the heat transfer efficiency of the gas in the tubes. Specific coils such as Figure 4 , 5 As shown, the tube body 7 of the coil is a stainless steel tube with a geometric dimension of Φ32×1.0 (mm), and a stainless steel core tube 8 is installed in the tube body. The geometric dimension of the core tube is Φ8×1 (mm), and the distance between the tube body and the core tube There are 9 inner fins installed between them, and the finning ratio is 7. The parameters of other struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com