Method for reducing grain size of AC foaming agent

A foaming agent and particle size technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of urea derivatives, etc., can solve problems affecting the quality of foam products, yellowing of the surface of foam products, and affecting the quality of foaming , to achieve the effect of reducing foaming temperature, reducing corrosion and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

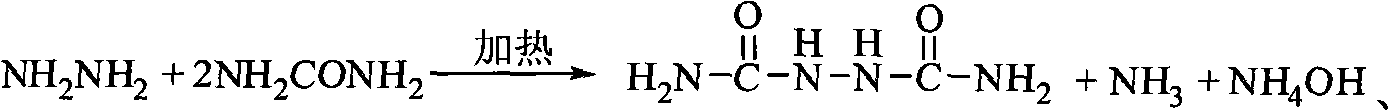

[0035] 1. Synthetic biurea

[0036] Mix 15g (0.255mol) of hydrazine hydrate and a certain amount of water into a 60% (mass fraction) hydrazine hydrate aqueous solution, add it to a 250ml round bottom flask, add hydrazine hydrate and urea in a certain ratio, and then add reaction catalyst A, The amount added is 1% of the amount of hydrazine hydrate. Condense under heating conditions for 6 hours, and the reaction temperature is 106°C. When the hydrazine content in the solution is less than 0.1g / L, the reaction reaches the end. The reaction solution is cooled to room temperature, filtered, and the biurea is washed repeatedly with water to remove NH 4 OH, dry. The purity of the product biurea is not less than 98%, the melting point is 253-256°C, and the yield (calculated as hydrazine hydrate) is 95%. The ammonia gas generated by the reaction can be recovered (CN1580677, CN1393405, CN1381442, CN86104483) or passed to the Raschig process to generate hydrazine hydrate.

[0037] The abov...

Embodiment 3

[0046] 1. Synthetic biurea

[0047] Mix 15g (0.255mol) of hydrazine hydrate and a certain amount of water into a 60% (mass fraction) hydrazine hydrate aqueous solution, add it to a 250ml round bottom flask, add hydrazine hydrate and urea in a certain ratio, and then add reaction catalyst A, The amount added is 1% of the amount of hydrazine hydrate. Condense under heating conditions for 6 hours, and the reaction temperature is 110℃. When the hydrazine content in the solution is less than 0.1g / L, the reaction reaches the end. The reaction solution is cooled to room temperature, filtered, and the biurea is washed repeatedly with water to remove NH 4 OH, dry. The purity of the product biurea is not less than 98%, the melting point is 253-256°C, and the yield (calculated as hydrazine hydrate) is 95%. The ammonia gas generated by the reaction can be recovered (CN1580677, CN1393405, CN1381442, CN86104483) or passed to the Raschig process to generate hydrazine hydrate.

[0048] The above...

Embodiment 4

[0057] 1. Synthetic biurea

[0058] Mix 15g (0.255mol) of hydrazine hydrate and a certain amount of water into a 60% (mass fraction) hydrazine hydrate aqueous solution, add it to a 250ml round bottom flask, add hydrazine hydrate and urea in a certain ratio, and then add reaction catalyst A, The amount added is 1% of the amount of hydrazine hydrate. Condense under heating conditions for 6 hours, the reaction temperature is 100 ℃, when the hydrazine content in the solution is less than 0.1g / L, the reaction reaches the end, the reaction solution is cooled to room temperature, filtered, and the biurea is washed repeatedly with water to remove NH 4 OH, dry. The purity of the product biurea is not less than 98%, the melting point is 253-256°C, and the yield (calculated as hydrazine hydrate) is 95%. The ammonia gas generated by the reaction can be recovered (CN1580677, CN1393405, CN1381442, CN86104483) or passed to the Raschig process to generate hydrazine hydrate.

[0059] The above re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com