Sintered light-weight environment-friendly brick produced from electroplating sludge and manufacture method thereof

A technology for electroplating sludge and a manufacturing method, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as environmental hazards, polluted soil and groundwater resources, complex electroplating sludge components, etc. Energy, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

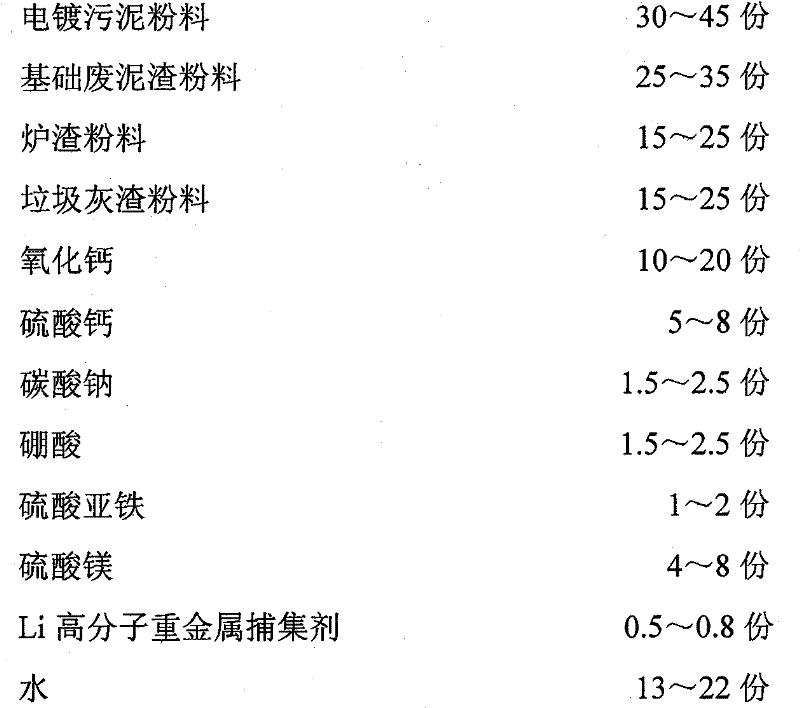

Method used

Image

Examples

Embodiment 1

[0048] The mold electroplating processing plant adopts large-scale mechanical electroplating equipment such as intelligent oxidation, linear electroplating, intelligent copper, nickel, chromium electroplating, hydraulic electroplating, automotive-specific coating, intermediate frequency magnetic control coating, decorative vacuum coating, and multi-functional ion coating. Surface sandblasting, polishing, rolling, polishing, brushing, large mechanical electroless nickel plating, large It is a kind of solid waste that is separated from the waste sand and industrial wastewater produced in the production process of chemical nickel plating and aluminum alloy direct plating of printer bearings after treatment. After dehydration, deodorization, disinfection, chelation treatment, drying, and then rolling and sorting, it is made into a powder with a particle size of less than -3mm;

[0049] Solid waste such as waste sediment generated during the construction of urban residential constr...

Embodiment 2

[0054] Get the electroplating sludge powder material 35kg of embodiment 1, basic waste sludge powder material 30kg, slag powder material 18kg, garbage ash powder material 18kg, particle diameter be the calcium oxide 13kg of 0.2mm, calcium sulfate 6kg, sodium carbonate 1.8kg , 1.8kg of boric acid, 1.2kg of ferrous sulfate, 5kg of magnesium sulfate, 0.6kg of Li macromolecule heavy metal collector and 15kg of water, the above-mentioned raw materials are mixed and stirred with a twin-shaft mixer to become moist, and then extruded into a rectangular shape using a vacuum extruder The strip shape is cut and formed by a blank cutting machine, and the light-weight environmentally friendly adobe of electroplating sludge is made under a pressure of 23Mpa. After 7 days of natural drying, the formed and naturally dried electroplating sludge environmentally friendly adobe is sent to the tunnel by a battery car The kiln is roasted, and after roasting, it is made into electroplated sludge sint...

Embodiment 3

[0056] Get embodiment 1 electroplating sludge powder 45kg, basic waste sludge powder 25kg, slag powder 25kg, garbage ash powder 15kg, particle diameter is the calcium oxide 20kg of-0.2mm, calcium sulfate 8kg, sodium carbonate 2.5kg , 2.5kg of boric acid, 2kg of ferrous sulfate, 8kg of magnesium sulfate, 0.8kg of Li macromolecule heavy metal collector and 22kg of water, mix and stir the above-mentioned raw materials to be moist, then extrude with mechanical vibration and form under a pressure of 30Mpa After 7 days of natural drying of the electroplating sludge lightweight hollow blocks, the formed and naturally dried electroplating sludge lightweight hollow blocks are sent to the tunnel kiln for roasting by a battery car, and after roasting, the electroplating sludge light Quality hollow block products. After testing, the average compressive strength is: 8.3Mpa, the minimum value of a single block is: 7.2Mpa, the dry apparent density is: 1022kg / m3, and the drying shrinkage rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com