Back-light black-surface silicon solar battery structure and production method thereof

A solar cell and backlight technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problem of inability to absorb, and achieve the effects of increasing photocurrent, avoiding open circuit voltage, and improving photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

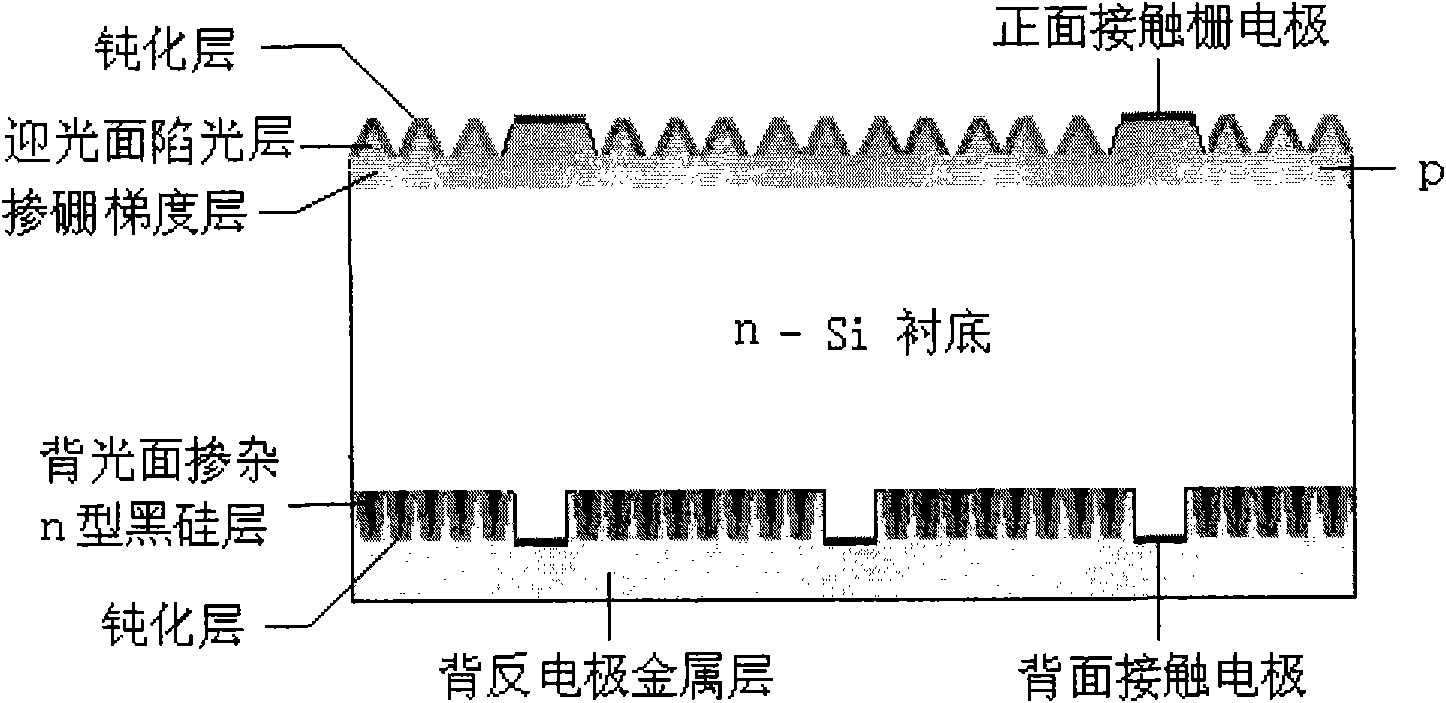

[0046] Embodiment 1: The backlight black silicon solar cell structure on the n-type silicon-based substrate see figure 2 , the implementation process is as follows: on the front side of the n-type silicon-based substrate, a boron-doped gradient layer is formed by boron diffusion or deposition of gradient boron-doped polysilicon or gradient boron-doped amorphous silicon, and the boron-doped gradient layer is woven by chemical etching. structure or laser irradiation to form a light-trapping layer on the light-receiving side; on the back of the n-type silicon-based substrate, make black silicon doped with chalcogenide impurities by laser irradiation to form a back-light-doped n-type black silicon layer; The silicon oxide dielectric passivation is performed on the light-facing and back-light sides of the battery, and the front contact gate electrode, the back contact electrode, and the metal layer of the back-counter electrode are made respectively, that is, the back-light black si...

Embodiment 2

[0047] Example 2: The structure of black silicon solar cells on the backlight surface with gradient phosphorus doping introduced on the n-type silicon-based substrate is shown in image 3 , the implementation process is as follows: on the back of the n-type silicon-based substrate, a phosphorous-doped gradient layer is formed from the surface to the inner surface and the phosphorus concentration is gradually reduced by diffusing or depositing a gradient phosphorus-doped polysilicon or gradient phosphorus-doped amorphous silicon layer. The surface of the phosphorus-doped gradient layer is irradiated with black silicon doped with chalcogenide impurities by laser light to form an n-type black silicon layer doped on the backlight surface; on the front side of the n-type silicon-based substrate, boron-doped polycrystalline silicon or Gradient boron-doped amorphous silicon forms a boron-doped gradient layer with decreasing boron concentration from the surface to the inside, and a lig...

Embodiment 3

[0048] Example 3: The backlight black silicon solar cell structure on the p-type silicon-based substrate see Figure 4 , the implementation process is as follows: on the front side of the p-type silicon-based substrate, a light-trapping layer on the light-facing surface is formed by chemical etching or laser irradiation; black silicon to form a doped n-type black silicon layer on the backlight surface; then perform silicon oxide dielectric passivation on the light-facing and back-light sides of the battery according to the conventional process, and make the front contact gate electrode, the back contact electrode and the back-counter electrode metal layer respectively. That is, the fabrication of the backlight black silicon solar cell structure on the p-type silicon-based substrate is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com