Point contact Laterally Diffused Metal Oxide Semiconductor (LDMOS) structure transistor unit

A technology of transistor unit and point contact, which is applied in the direction of transistors, electrical components, semiconductor devices, etc., and can solve the problems such as the difficulty of further reducing the drain-source PN junction capacitance, the limitation of broadband microwave high-power applications of devices, and the large chip area of high-power devices. , to achieve the effect of satisfying broadband, reducing thermal resistance and dispersing heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

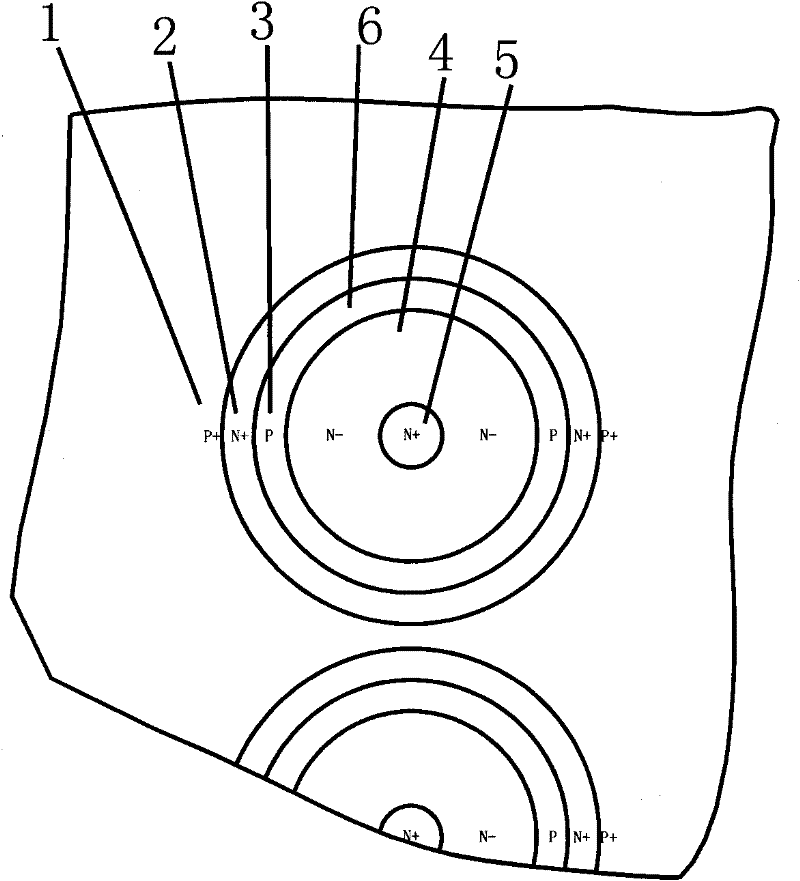

[0013] Control attached figure 1 , its structure is a point-contact LDMOS structure transistor unit, its structure is that the N+ doped drain region 5 is a circle or a regular polygon, forming a drain contact region; the periphery of the N+ doped drain region 5 is surrounded by an N-doped drift region 4; -The periphery of the doped drift region 4 is surrounded by a P-type doped channel region 3, and above the P-type doped channel region 3 is an N+ doped polysilicon gate 6; between the P-type doped channel region 3 and the N+ doped polysilicon gate 6 are separated by a silicon dioxide insulating layer; the P-type doped channel region 3 is surrounded by an N+ doped source region 2; the N+ doped source region 2 is surrounded by a P+ doped source region 1, and the P+ doped source region 1 The doping depth exceeds the thickness of the epitaxial layer, and the P+ doping source region 1 is connected to the P+ substrate; the P+ doping source region 1 and the N+ doping source region 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com