Preparation method of Pb-Sb-Cd alloy used for positive plate of battery

A technology of lead, antimony, cadmium, and positive plate, which is applied in the field of metallurgy, can solve the problems of increasing cost and difficulty of antimony, and achieve the effects of improving utilization rate, reducing cost and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

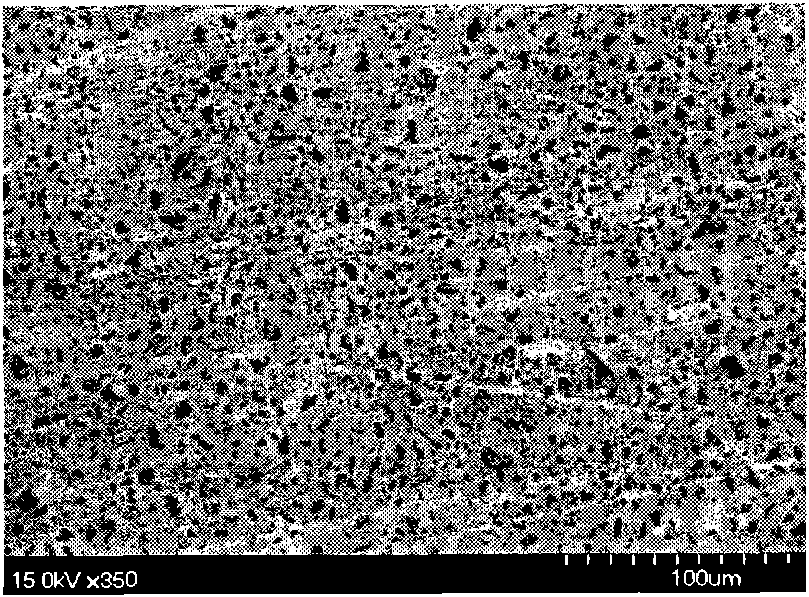

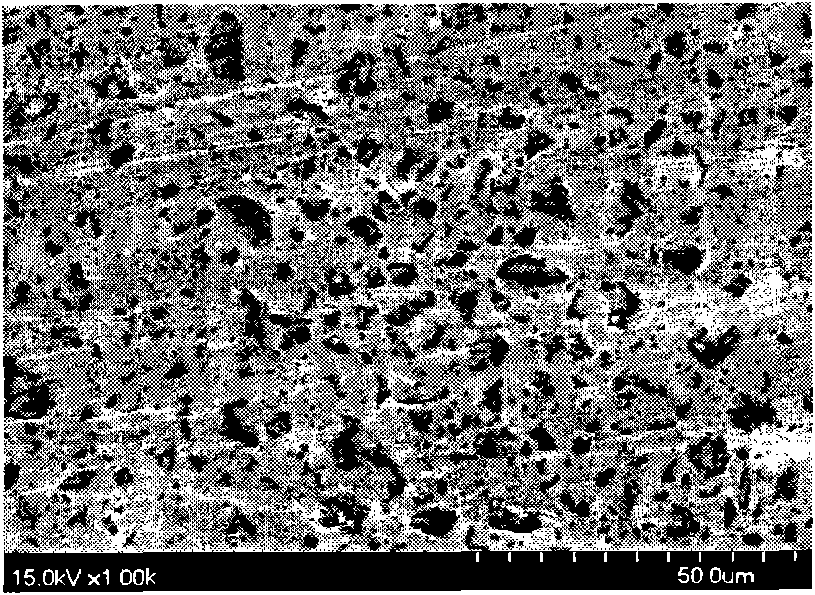

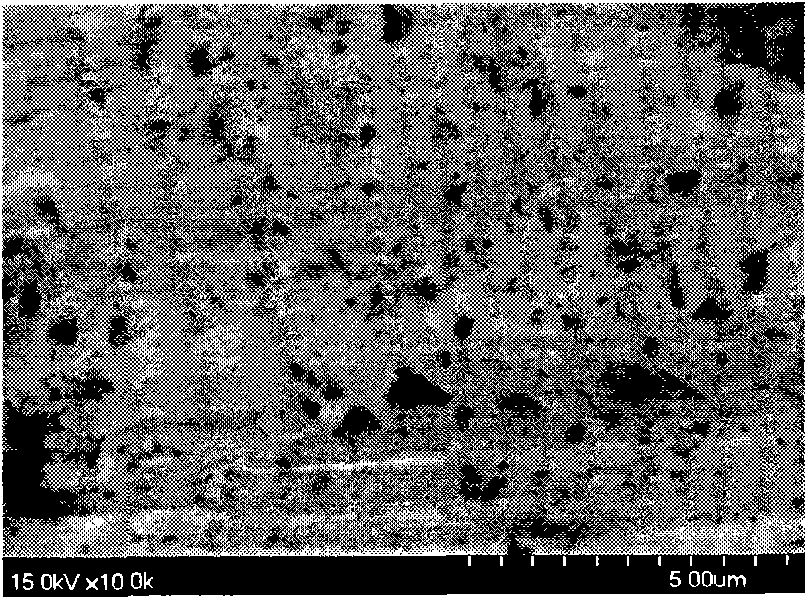

Image

Examples

Embodiment 1

[0025] (1) Heat 30 tons of reduced lead to make it melt, then heat up to 400°C after melting, add 150 kg of sodium hydroxide, and stir for 20 minutes. Sodium hydroxide forms dross with arsenic and tin, and the dross is removed to obtain liquid lead from which arsenic and tin have been removed.

[0026] (2) Lower the temperature of the lead liquid from which arsenic and tin have been removed to 320°C, divide it into 4 batches, add 50 kg of red phosphorus in total (after inspection, the quality of red phosphorus is 1.8 times the mass of copper in reduced lead), red phosphorus and copper form dross Float on the lead liquid, remove the dross, and obtain the lead liquid after copper removal.

[0027] (3) Add 300 kilograms of mother antimony to the lead liquid after copper removal at 420 DEG C, add mother antimony and stir for 30 minutes to obtain the lead liquid after adding antimony;

[0028] (4) The lead liquid after adding antimony is cooled to 400 ℃, then adds 500 kilograms of...

Embodiment 2

[0034] (1) Heat and reduce 30 tons of lead to make it melt, heat up to 500°C after melting, add 180 kg of sodium hydroxide, and stir for 30 minutes. Sodium hydroxide forms dross with arsenic and tin, and the dross is removed to obtain liquid lead from which arsenic and tin have been removed.

[0035] (2) Lower the temperature of the lead liquid from which arsenic and tin have been removed to 320°C, divide it into 4 batches, and add a total of 52 kg of red phosphorus (after inspection, the quality of red phosphorus is three times that of copper in reduced lead), red phosphorus and copper form dross Float on the lead liquid, remove the dross, and obtain the lead liquid after copper removal.

[0036] (3) Add 240 kilograms of mother antimony to the lead liquid after copper removal at 450 DEG C, add mother antimony and stir for 30 minutes to obtain the lead liquid after adding antimony;

[0037] (4) The lead liquid after adding antimony is cooled to 400 ℃, then adds 500 kilograms ...

Embodiment 3

[0043] (1) Heat 30 tons of reduced lead to make it melt, then heat up to 450°C after melting, add 200 kg of sodium hydroxide, and stir for 20 minutes. Sodium hydroxide forms dross with arsenic and tin, and the dross is removed to obtain liquid lead from which arsenic and tin have been removed.

[0044] (2) Lower the temperature of the lead liquid from which arsenic and tin have been removed to 320°C, divide it into 4 batches, and add a total of 55 kg of red phosphorus (after inspection, the quality of red phosphorus is twice the mass of copper in reduced lead), red phosphorus and copper form dross Float on the lead liquid, remove the dross, and obtain the lead liquid after copper removal.

[0045] (3) Add 400 kilograms of mother antimony to the lead liquid after copper removal at 420 DEG C, add mother antimony and stir for 30 minutes to obtain the lead liquid after adding antimony;

[0046] (4) The lead liquid after adding antimony is cooled to 390 ℃, then adds 505 kilograms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com