Electromagnetic brake, friction piece thereof and friction piece manufacture method

A technology of electromagnetic brakes and friction parts, applied in elevators, hoisting devices, transportation and packaging, etc., can solve the problems of difficult control of spring adjustment, small wear amount, poor performance repeatability, etc., to improve safe working conditions and stabilize static and dynamic friction. coefficient, the effect of improving the contact wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] 1. The production process of beryllium bronze friction plate: punching and blanking→stamping→aging hardening treatment, the details are as follows:

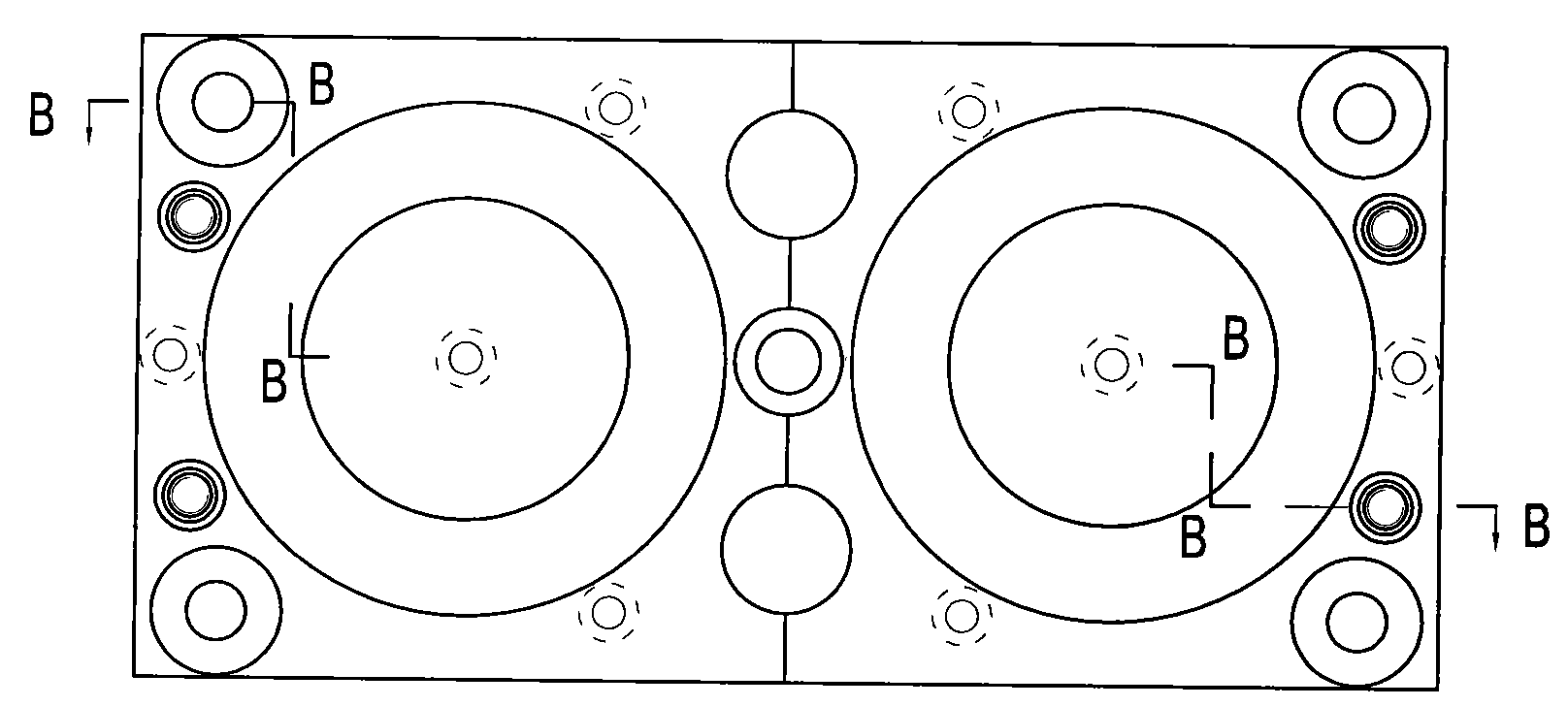

[0100] 1. Punching and blanking: select the soft QBe2.0 (C17200) beryllium bronze sheet with a thickness of 1.1mm and solution treatment, put it on an open tilting press and punch it into a square as a whole, and punch out four Circular through hole 41 and four square anti-off notches 42, four through holes 41 are evenly distributed around the center point of the square plate, four anti-off notches 42 are symmetrically arranged on two opposite edges, and anti-off notch 42 near the other two edges. see Figure 16 , 17 .

[0101] The soft beryllium bronze plate after solution treatment is blanked by an open tilting press to make the part flat and free of burrs, and to effectively prevent bending and cracking during stamping. In addition, beryllium bronze also has the advantages of being non-magnetic and not generating spar...

Embodiment 2

[0115] 1. The production process of beryllium bronze friction plate:

[0116] 1. Punching and blanking: use a beryllium bronze plate with a thickness of 1.1mm;

[0117] 3. Age hardening treatment: Heating in a vacuum furnace, keeping the temperature at 290°C for 4 hours.

[0118] 2. Die-casting molding: use beryllium bronze that has been stamped and aged as an insert, and position it in a preheated mold at 180°C. The mold retention time is 6.0s, the injection speed of aluminum water is 3.3m / s, and the injection force is 3500N , die-casting temperature 680 ℃ molding, holding time 4.5s, and then water cooling.

[0119] Other content of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0121] 1. The production process of beryllium bronze friction plate:

[0122] 1. Punching and blanking: use beryllium bronze plate with a thickness of 1.4mm;

[0123] 3. Age hardening treatment: Heating in a vacuum furnace, keeping the temperature at 260°C for 2.8 hours.

[0124] 2. Die-casting molding: use stamped and aged-treated beryllium bronze as an insert, position it in a preheated mold at 200°C, leave the mold for 7.5s, inject speed of aluminum water at 3.8m / s, and inject force at 3700N , die-casting temperature 660 ℃ molding, holding time 3.0s, and then water cooling.

[0125] Other content of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com