Preparation method of positive-electrode porous material used by lithium ion battery

A technology for lithium-ion batteries and porous materials, which is applied in the field of preparation of positive electrode materials for lithium-ion batteries, can solve the problems of insufficient contact of raw materials, etc., to overcome the irregular shape of the product, easy to coat the excellent surface, and increase the deintercalation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

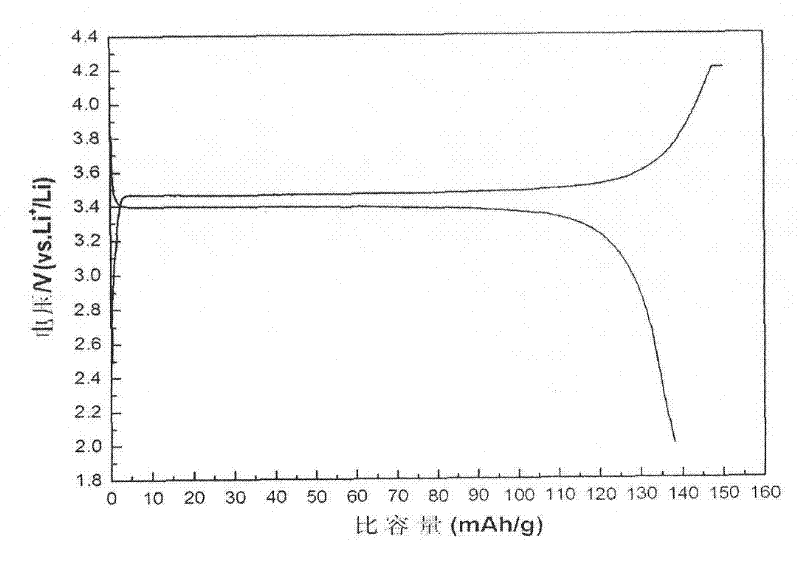

[0038] Homogenization treatment of raw materials: Weigh lithium nitrate, ferric nitrate, and ammonium dihydrogen phosphate according to the molar ratio of Li:Fe:P of 1:1:1, dissolve in water, and add carbon black according to the molar ratio of C:Fe to 3:1 , And then add 5g surfactant Tween 80, and make 1000mL suspension slurry (solid content 20wt%) with deionized water. After the mixture was sufficiently stirred in a high-speed disperser for 2 hours, a well-dispersed suspension slurry was obtained as the precursor liquid A.

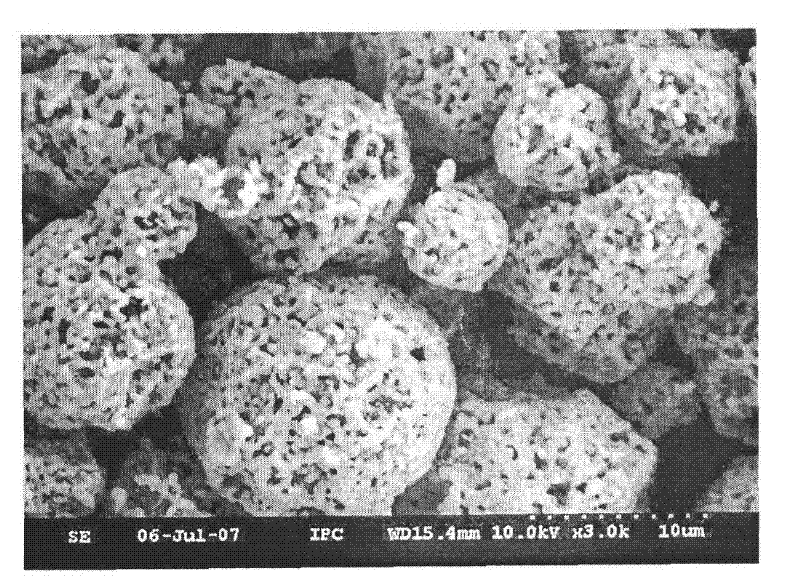

[0039] Precursor preparation: The precursor solution A is dried and dehydrated with a centrifugal spray dryer. Under a carrier gas pressure of 0.2MPa, the slurry is fed into the spray dryer at a rate of 15mL / min, and the inlet temperature and outlet temperature are kept at 260℃. At around 100°C, the dried powder is collected in a cyclone to obtain a precursor B, which is a black powder.

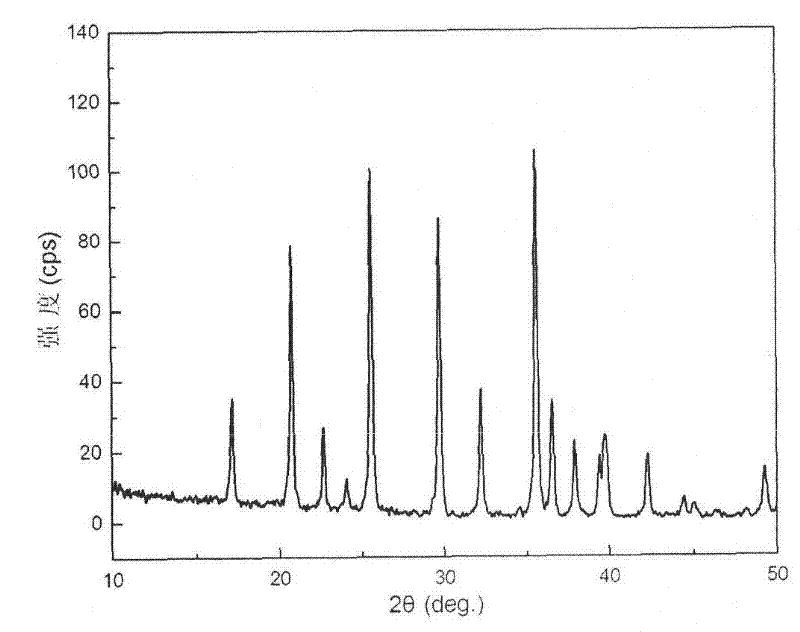

[0040] Heat treatment: Place the precursor B in a tube furnace under a...

Embodiment 2

[0043] Homogenization treatment of raw materials: Weigh lithium carbonate, ferric nitrate, and phosphoric acid according to the molar ratio of Li:Fe:P of 1:1:1, dissolve in water, add carbon black according to the molar ratio of C:Fe of 2:1, and then add 5g surfactant Tween 80 was prepared with deionized water to make 1000mL suspension slurry (solid content 20wt%). After the mixture was sufficiently stirred in a sand mill for 2 hours, a well-dispersed suspension slurry was obtained as the precursor liquid A.

[0044] Precursor preparation: The precursor solution A is dried and dehydrated with a centrifugal spray dryer. Under a carrier gas pressure of 0.2MPa, the slurry is fed into the spray dryer at a rate of 15mL / min, and the inlet temperature and outlet temperature are kept at 260℃. At around 100°C, the dried powder is collected in a cyclone to obtain a precursor B, which is a black powder.

[0045] Heat treatment: Place precursor B in a tube furnace under argon atmosphere and h...

Embodiment 3

[0048] Homogenization treatment of raw materials: Weigh lithium nitrate, ferric oxide and phosphoric acid according to the molar ratio of Li:Fe:P of 1:1:1, dissolve them in water, and add acetylene black according to the molar ratio of C:Fe of 3:1. Then, 10 g of surfactant Tween 80 was added, and a 1000 mL suspension slurry (solid content 20 wt%) was prepared with deionized water. After the mixture was sufficiently stirred in a high-speed disperser for 2 hours, a well-dispersed suspension slurry was obtained as the precursor liquid A.

[0049] Precursor preparation: The precursor solution A is dried and dehydrated with a centrifugal spray dryer. Under a carrier gas pressure of 0.2MPa, the slurry is added to the spray dryer at a rate of 10mL / min, and the inlet temperature and outlet temperature are kept at 260℃. At around 100°C, the dried powder is collected in a cyclone to obtain a precursor B, which is a black powder.

[0050] Heat treatment: Place the precursor B in a tube furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com