Resource utilization process for clean hemp biological degumming and waste thereof

A technology for biological degumming and waste, applied in the field of resource utilization technology, can solve problems such as affecting yield and quality, limited microbial enzyme production capacity, serious environmental pollution, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

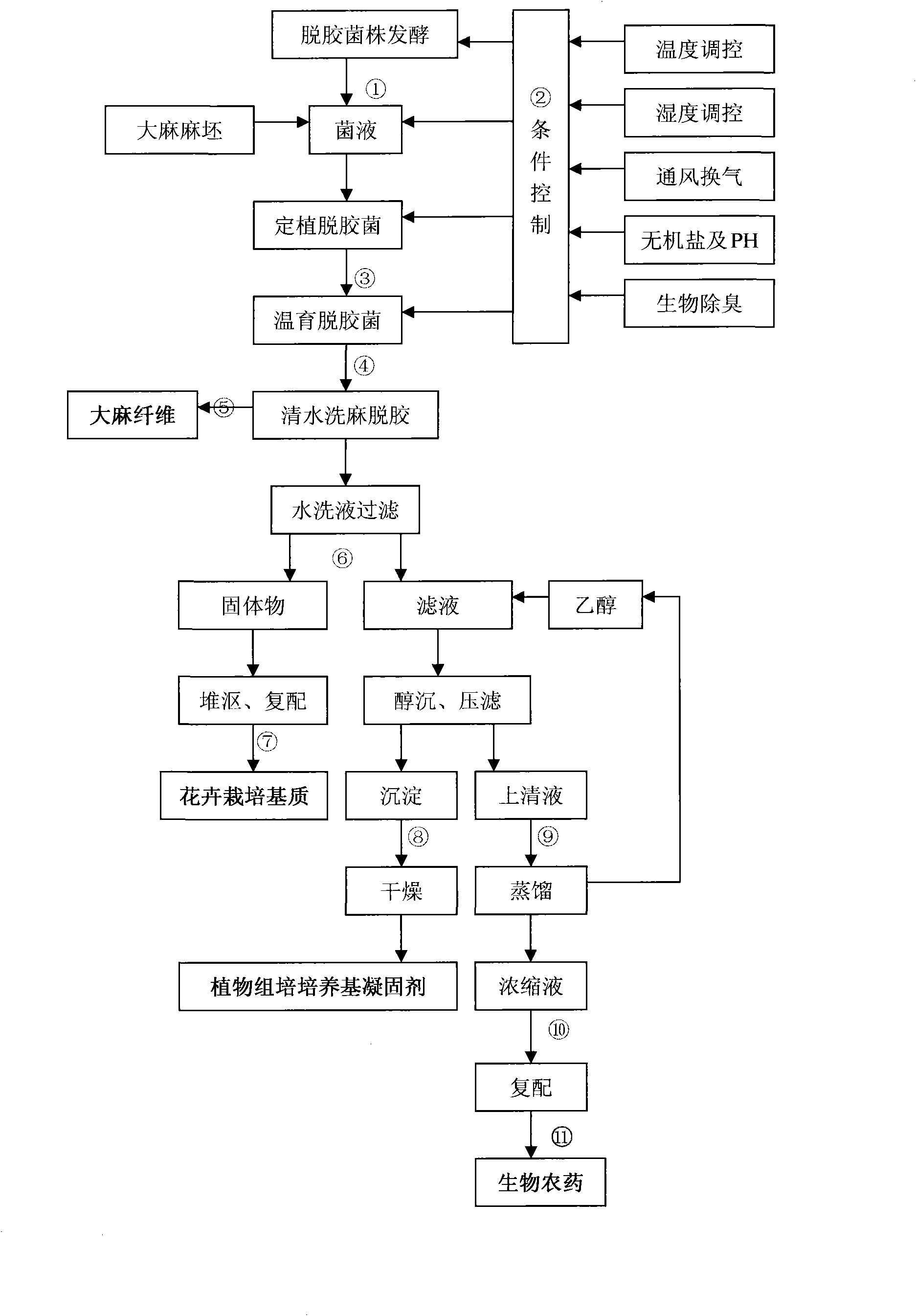

Method used

Image

Examples

Embodiment 1

[0034] 1 Materials and Instruments

[0035] Hemp hemp raw material (purchased and provided by Lu'an Xishan Biotechnology Co., Ltd.), sodium hydroxide, hydrochloric acid, (NH 4 ) 2 SO 4 :KH 2 PO 4 : MgSO 4 : FeSO 4 All are domestic analytically pure, beef extract and peptone are of biochemical grade, and bran, rice husk, sawdust, etc. are purchased from local markets.

[0036] Ultra-clean workbench, constant temperature incubator, shaker, fully automatic pilot stainless steel fermentation tank (SGD1000), 5m 3 Liquid storage tank, hemp soaking pool (2m×4m×6m), bacterial solution pool (1.5m×1m×5m), incubation room (300m 2Separated into three independent spaces), hemp washing equipment, ceramic membrane filter, plate and frame filter press, cooking concentrator, alcohol recovery equipment (JS-500)

[0037] 2 Experimental methods

[0038] 2.1 Culture of degumming bacteria

[0039] Degummed strain: Bacillus cereus "WM20091116" strain, isolated from retting hemp phloem by r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com