Forward osmosis membrane bioreactor

A technology of bioreactor and forward osmosis membrane, which is applied in the field of membrane separation, can solve problems such as increased investment and operating costs, hindering the promotion of MBR technology, and ineffective practical effects, so as to overcome organic pollution, shorten biochemical reaction time, and strengthen biochemical The effect of the reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

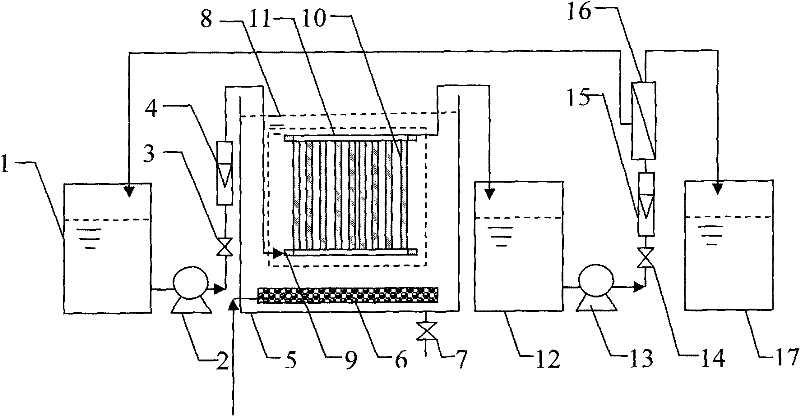

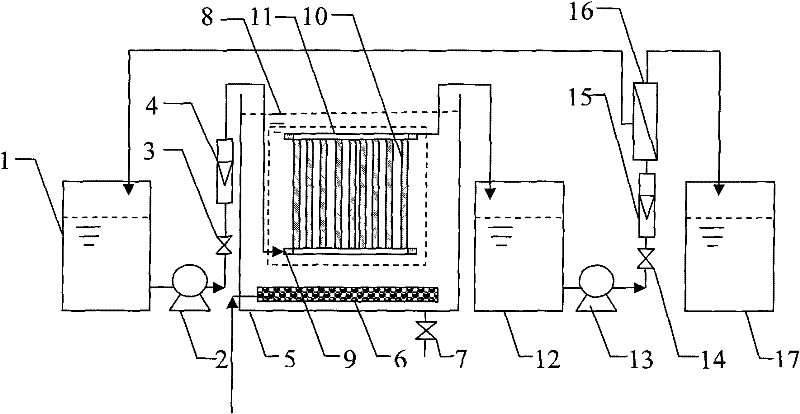

Embodiment 1

[0028]Activated sludge is put into the forward osmosis membrane bioreactor 5 of the present invention and domesticated, and will contain COD be 40g / L, BOD5 be 0.3g / L, NH 4 - Sewage with N of 0.2g / L and SS of 0.2g / L is put into the membrane bioreactor 5; connected to the forward osmosis system, the hollow fiber cellulose acetate membrane 10 module is used as the forward osmosis membrane module 8, soaked in the membrane bioreactor In the sewage in the reactor 5, the sodium chloride solution of 20g / L is used as the drive solution, and injected into the drive solution storage tank 1; the brine concentration system is connected, and the concentration system used is a conventional reverse osmosis system; the forward osmosis control system is in Operate at a temperature of 12°C and a pH of 6.5. The forward osmosis MBR system operates stably, and the treatment effect is good. The COD and BOD of the effluent are 0, and the NH 4 -N was not detected, SS was not detected, and the quality...

Embodiment 2

[0030] The activated sludge is put into the membrane bioreactor 5 for acclimation, and will contain COD as 70g / L, BOD5 as 10g / L, NH 4 - Sewage with N of 0.5g / L and SS of 5g / L is put into the membrane bioreactor 5; connected to the forward osmosis system, the roll-type polyamide composite membrane 10 module is used as the forward osmosis membrane module 8, soaked in the membrane bioreactor In the sewage in the device 5, 40g / L magnesium chloride solution is used as the drive solution, and injected into the drive solution storage tank 1; the brine concentration system is connected, and the concentration system used is a conventional nanofiltration system; the forward osmosis control system operates at a temperature of 20°C , run at pH 7.0. The forward osmosis MBR system operates stably and the treatment effect is good. The COD of the effluent quality varies from 0 to 5mg / L, the BOD varies from 0 to 1mg / L, and the NH 4 -N was not detected, SS was not detected, and the quality of ...

Embodiment 3

[0032] Put the activated sludge into the membrane bioreactor 5 for acclimation, and will contain COD as 100g / L, BOD5 as 50g / L, NH 4 - Sewage with N of 1.0g / L and SS of 10g / L is put into the membrane bioreactor 5; connected to the forward osmosis system, the hollow fiber polybenzimidazole membrane 10 module is used as the forward osmosis membrane module 8 to soak in the membrane bioreactor In the sewage in the device 5, the mixed solution of 60g / L sodium chloride and 1g / L sucrose is used as the driving liquid, and injected into the driving liquid storage tank 1; the brine concentration system is connected, and the concentration system used is a conventional nanofiltration system ; The forward osmosis control system operates at a temperature of 20°C and a pH of 8.0. The forward osmosis MBR system operates stably and the treatment effect is good. The COD of the effluent quality varies from 0 to 3mg / L, the BOD varies from 0 to 1mg / L, and the NH 4 -N was not detected, SS was not d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com