Method for synthesizing Nb/Nb5Si3 composite materials at high temperature through microwave induced self propagating

A self-propagating high-temperature, composite material technology, applied in the field of microwave-induced self-propagating high-temperature synthesis of Nb/Nb5Si3 composite materials, can solve the problem of no Nb5Si3 formation, and achieve the effect of avoiding oxidation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

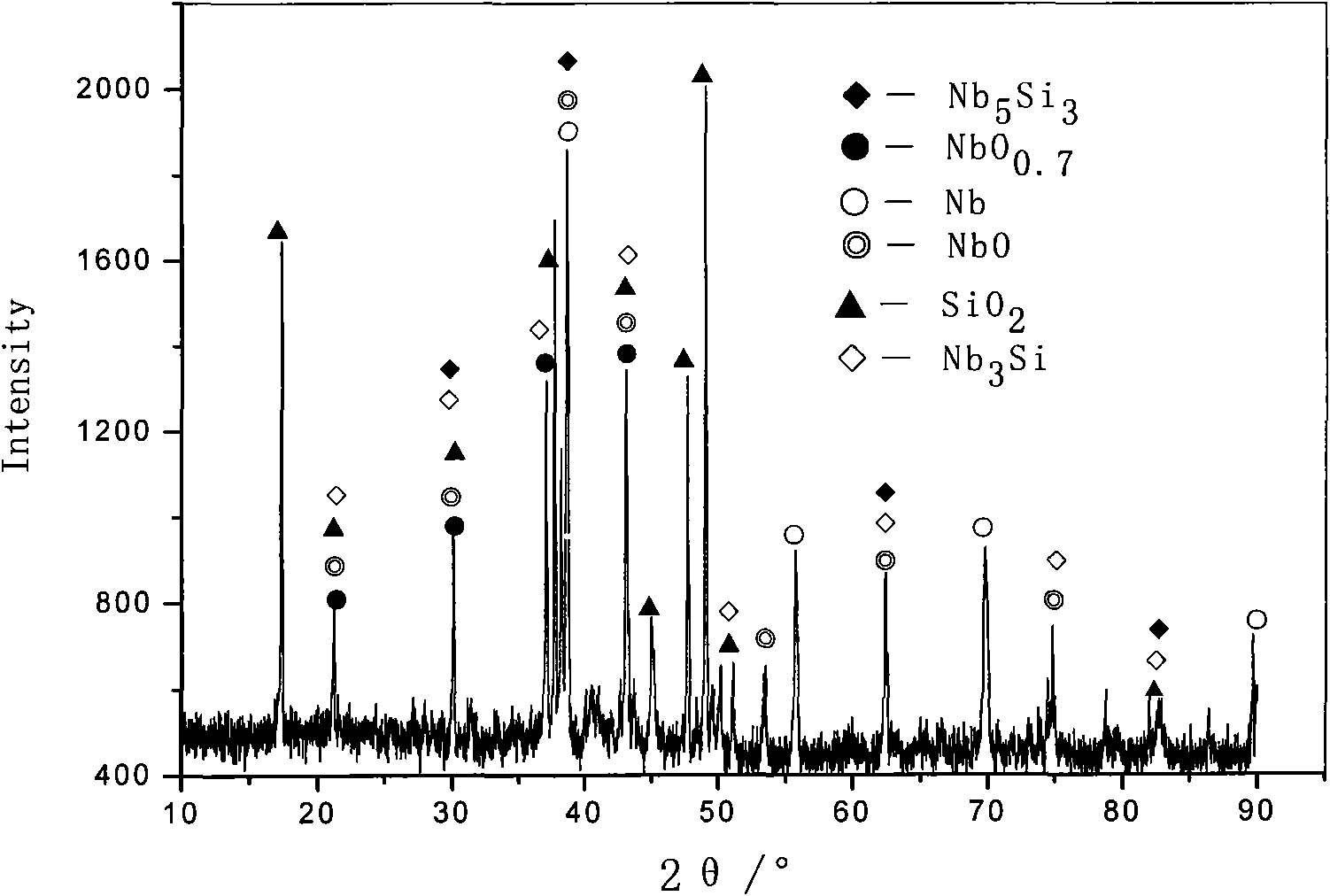

Embodiment 1

[0033] Nb-37.5at% Si sample has been self-propagating sintering under the protection of argon after evacuation, and Nb and Si powder are pressed by Nb 5 Si 3 The chemical formula of the preparation Nb:Si atomic ratio is the composite powder of 62.5:37.5, ball milled in the planetary ball mill for 10h, the ball milling medium is alcohol, the ball-to-material ratio is 3:1, and 2wt% stearic acid is added as a process control agent. The samples after ball milling were dried and molded under a pressure of 300MPa. The molded sample is placed in a microwave cavity, vacuumed to 2Pa, then filled with fluid argon, and self-propagating sintering is carried out under the protection of argon. Start the microwave source, the heating rate is 10-40°C / min, the sintering temperature is 1200°C, and the holding time is 15min. After the furnace cools down, take out the sample. The fired sample is mainly composed of niobium oxide, SiO 2 and a small amount of Nb 3 Si and Nb 5 Si 3 composition...

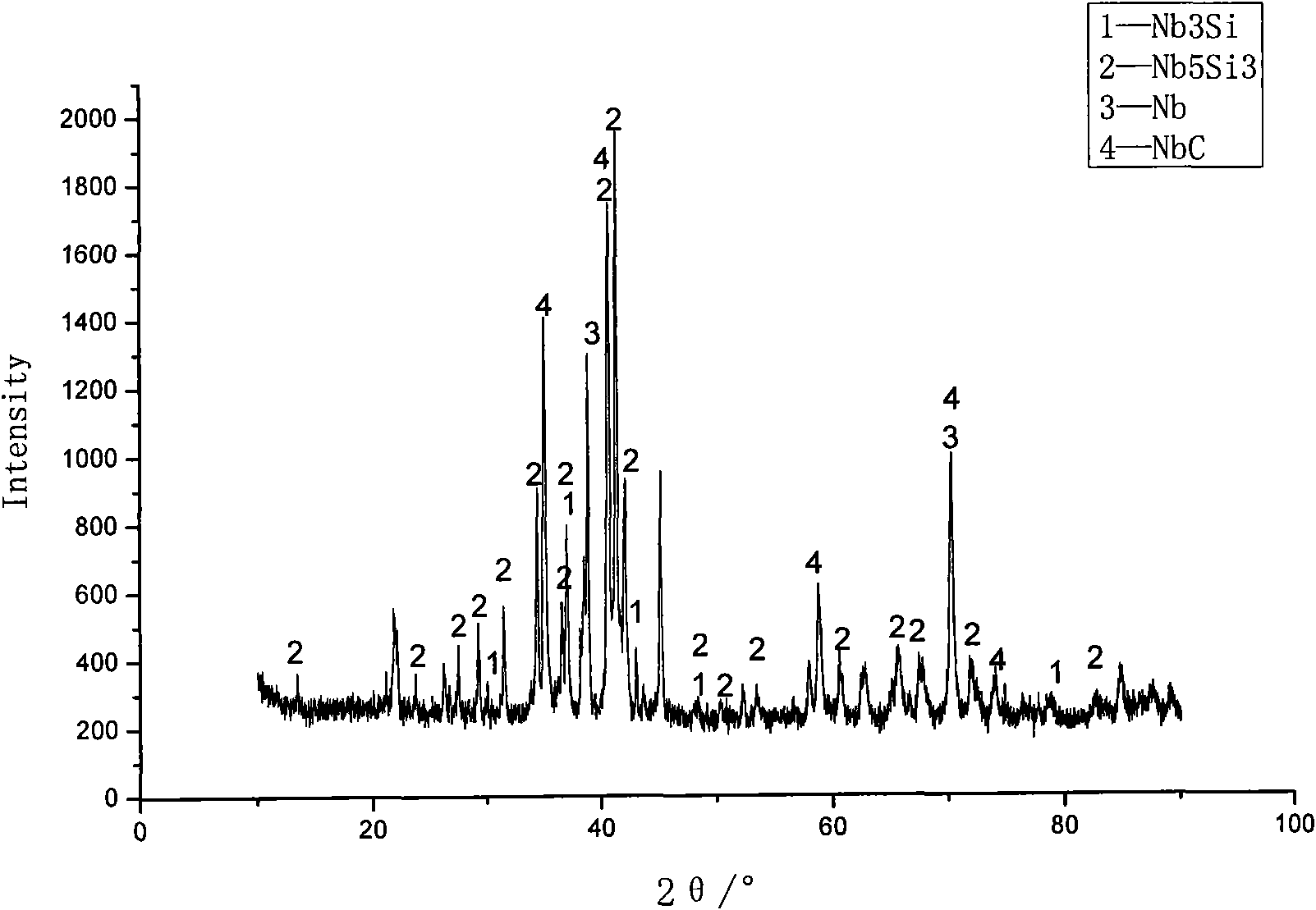

Embodiment 2

[0035] Nb-18.7at% Si samples embedded in Al 2 o 3 Self-propagating sintering in +SiC+C powder

[0036] Prepare Nb and Si powders according to the eutectic composition into composite powders with an atomic ratio of Nb:Si of 81.3:18.7, and mill them in a planetary ball mill for 10 hours. Fatty acid as a process control agent. The samples after ball milling were dried and molded under a pressure of 100 MPa. The molded sample was embedded in Al 2 o 3 +SiC+C powder and then put it into the microwave cavity, vacuumize to 2Pa, fill it with fluid argon, and carry out self-propagating sintering under the protection of argon. The ratio of the above-mentioned protective powder is Al 2 o 3 : 20wt%, SiC: 78wt%, C: 2wt%. Start the microwave source, the heating rate is 10-40°C / min, the sintering temperature is 1300°C, and the holding time is 30min. After the furnace cools down, take out the sample. The fired sample is mainly composed of Nb, Nb 5 Si 3 and a small amount of Nb 3 Si...

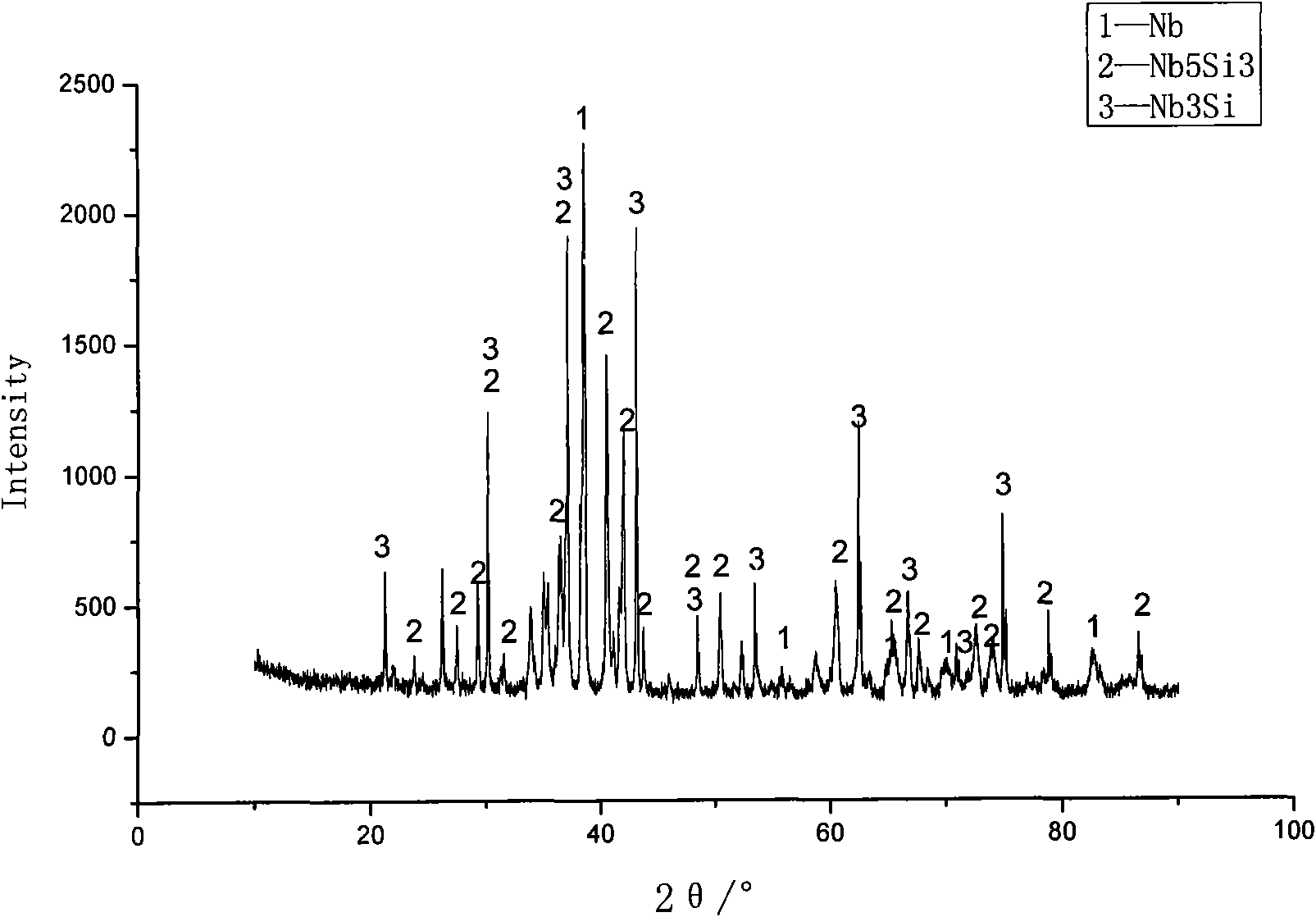

Embodiment 3

[0038] Nb-18.7at% Si samples embedded in Al 2 o 3 Self-propagating sintering in +SiC+Al powder

[0039] Prepare Nb and Si powders according to the eutectic composition into composite powders with an atomic ratio of Nb:Si of 81.3:18.7, and mill them in a planetary ball mill for 10 hours. Fatty acid as a process control agent. The samples after ball milling were dried and molded under a pressure of 300MPa. The molded sample was embedded in Al 2 o 3 +SiC+Al powder and then put it into the microwave cavity, vacuumize to 2Pa, fill it with fluid argon, and carry out self-propagating sintering under the protection of argon. The ratio of the above-mentioned protective powder is Al 2 o 3 : 18wt%, SiC: 80wt%, Al: 2wt%. Start the microwave source, the heating rate is 10-40°C / min, the sintering temperature is 1300°C, and the holding time is 30min. After the furnace cools down, take out the sample. The fired sample is mainly composed of Nb, Nb 5 Si 3 and a small amount of Nb 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com