Fluorescent powder using silicon-aluminum base nitrogen oxides as base materials and preparation method thereof

A nitrogen oxide and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of limited development, high temperature, complex preparation method of nitride phosphors, etc., to achieve optimized performance, reduced calcination temperature, high thermal stability Effects of sex and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

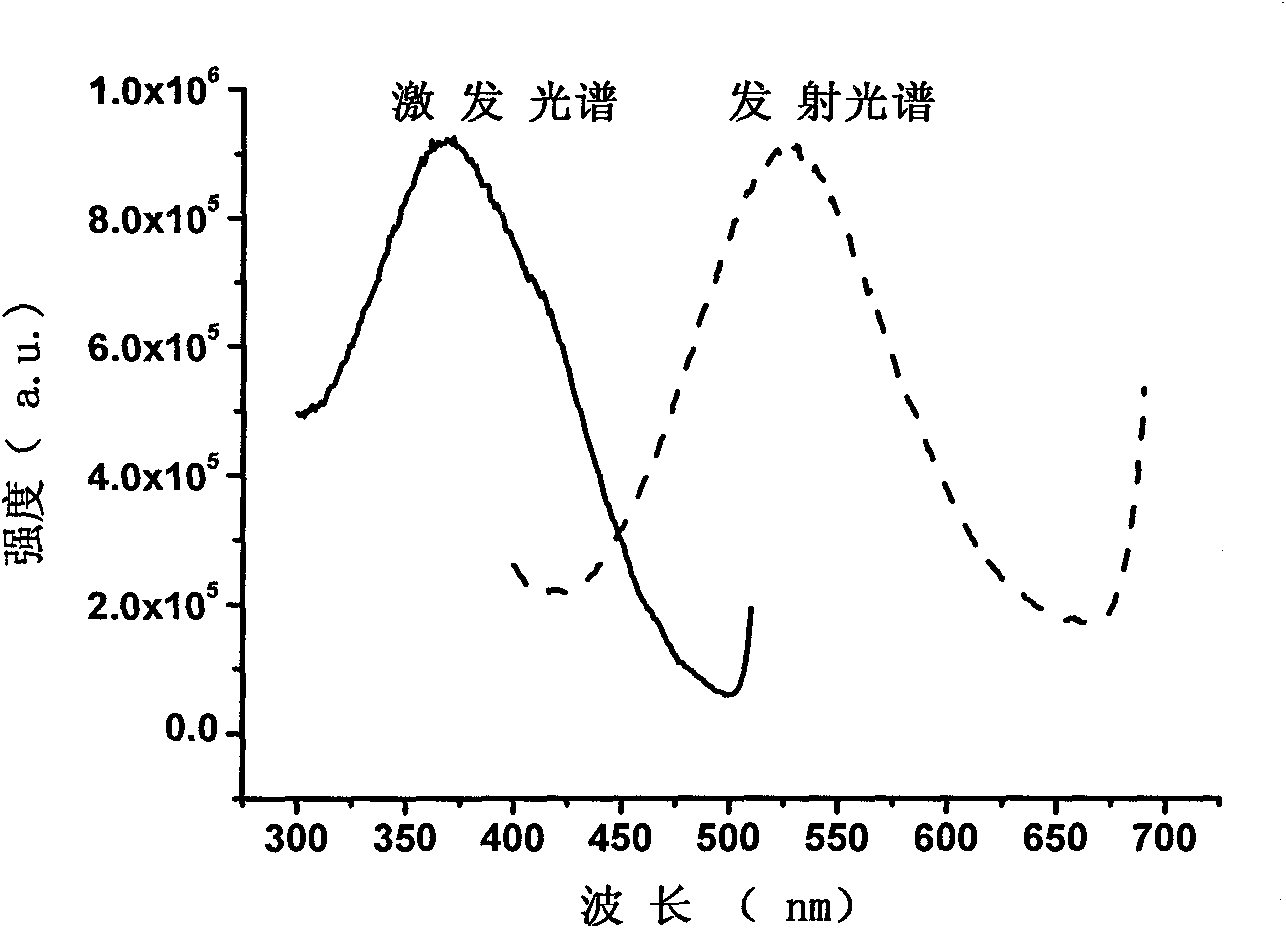

[0039] Sr 4.88 Li 2 al 2 Si 2 N 2 o 10 :0.12Eu 2+ Synthesis of phosphors.

[0040] Take by weighing 7.1 grams of strontium carbonate (purity 99%), 0.71 grams of lithium carbonate (purity 99%), 0.3 grams of silicon dioxide (purity 99%), 1.05 grams of aluminum oxide (purity 99%), 0.7 gram of silicon nitride (purity 99%) and 0.21 gram of europium oxide (purity 99.9%), the weighed raw materials are placed in an agate jar, and the powder is finely ground and mixed uniformly by grinding.

[0041] Then put the mixed raw materials in the corundum crucible, in the high temperature resistance furnace, H 2 / N 2 (5% / 95%) under the roasting atmosphere, in the high-temperature tube furnace, be heated to 1350 ℃ with the heating rate of 300 ℃ / hour, and keep 5 hours at this temperature, then slowly cool to room temperature; The sample of cooling is again Grind into a powder by a ball mill, put it into a graphite crucible, and 2 / N 2 (5% / 95%) under reducing atmosphere, in high-temper...

Embodiment 2

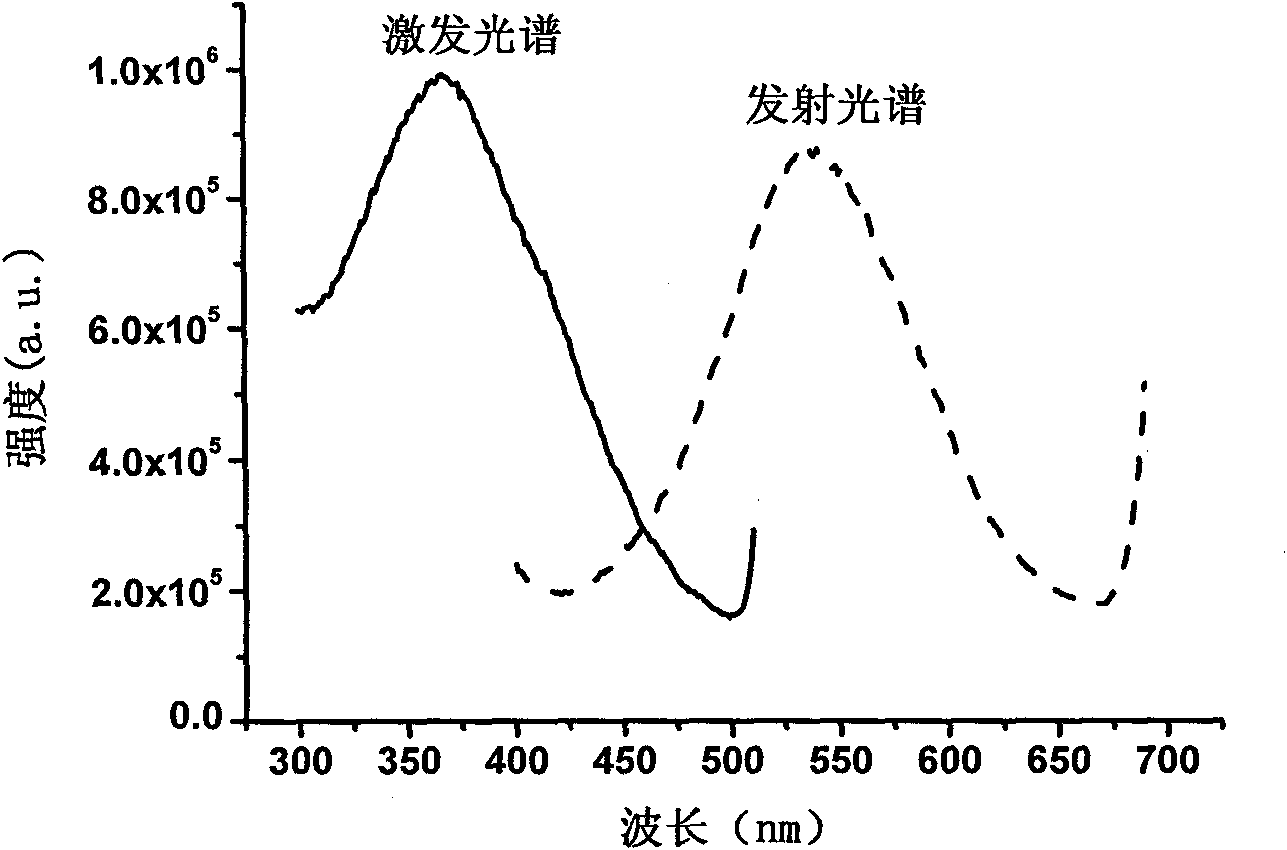

[0045] Sr 5.88 AlSi 3 N 3 o 9 :0.12Eu 2+ Synthesis of phosphors.

[0046] According to the stoichiometric ratio, weigh 8.6 grams of strontium carbonate, 0.45 grams of silicon dioxide, 0.51 grams of aluminum oxide, 1.05 grams of silicon nitride and 0.21 grams of europium oxide as raw materials, weigh 0.5 grams of strontium fluoride and 0.5 grams of barium fluoride As a co-solvent, put the weighed raw materials and co-solvent in an agate jar, grind the powder finely and mix it evenly.

[0047] Then put the mixed raw materials in the corundum crucible, in the high-temperature resistance furnace, under the CO reduction gas generated by the combustion of carbon particles in the air, in the high-temperature tube furnace, heat up to 1450°C at a heating rate of 200°C / hour , and kept at this temperature for 5 hours, then stopped heating, and slowly cooled to room temperature under the protection of CO reducing gas generated by the combustion of carbon particles in air.

[0048] T...

Embodiment 3

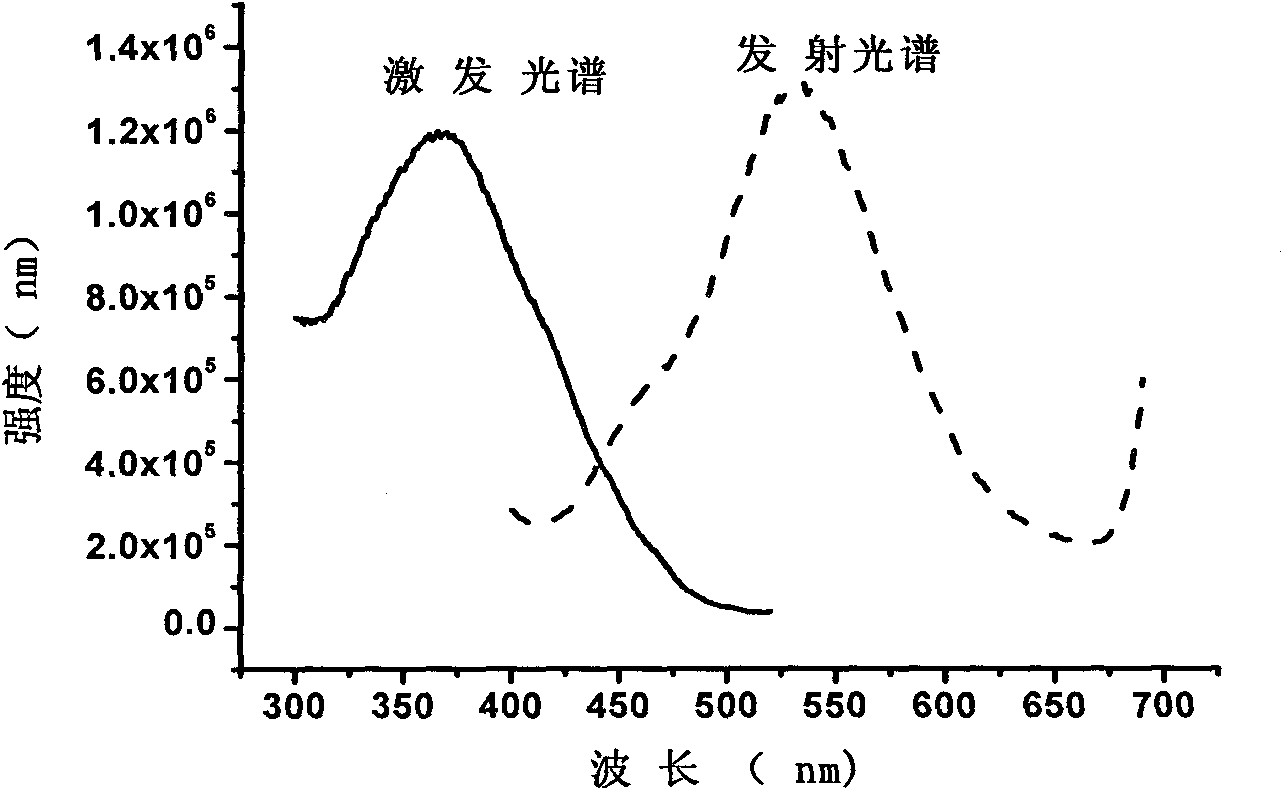

[0051] Sr 5.38 LiAlSi 3 N 3 o 9 :0.12Eu 2+ Synthesis of phosphors.

[0052] Take by weighing 7.82 grams of strontium carbonate (purity 99%), 0.352 grams of lithium carbonate (purity 99%), 0.45 grams of silicon dioxide (purity 99%), 0.51 grams of aluminum oxide (purity 99%), 1.05 One gram of silicon nitride (purity 99%) and 0.228 gram of europium fluoride (purity 99.99%) are used as raw materials, and the weighed raw materials are placed in an agate jar, and the powder is pulverized and mixed uniformly by grinding.

[0053] Then put the mixed raw materials in the corundum boat, in the high temperature resistance furnace, H 2 / N 2 (5% / 95%) under reducing atmosphere, in high-temperature tube furnace, be heated to 1250 ℃ with the rate of rise of 300 ℃ / hour, and keep 5 hours at this temperature, stop heating subsequently, in H 2 / N 2 (5% / 95%) slowly cooled to room temperature under the protection of reducing atmosphere.

[0054] The powder obtained by sintering was ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com