Method for preparing heat-resistant and abrasion-resistant composite guide carrier roller

A high temperature resistant and guiding technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of wear resistance, poor thermal shock resistance, short average life of guide rollers, etc., and achieve excellent resistance to high temperature oxidation and resistance. Wear performance, excellent hot hardness and high temperature wear resistance, the effect of strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

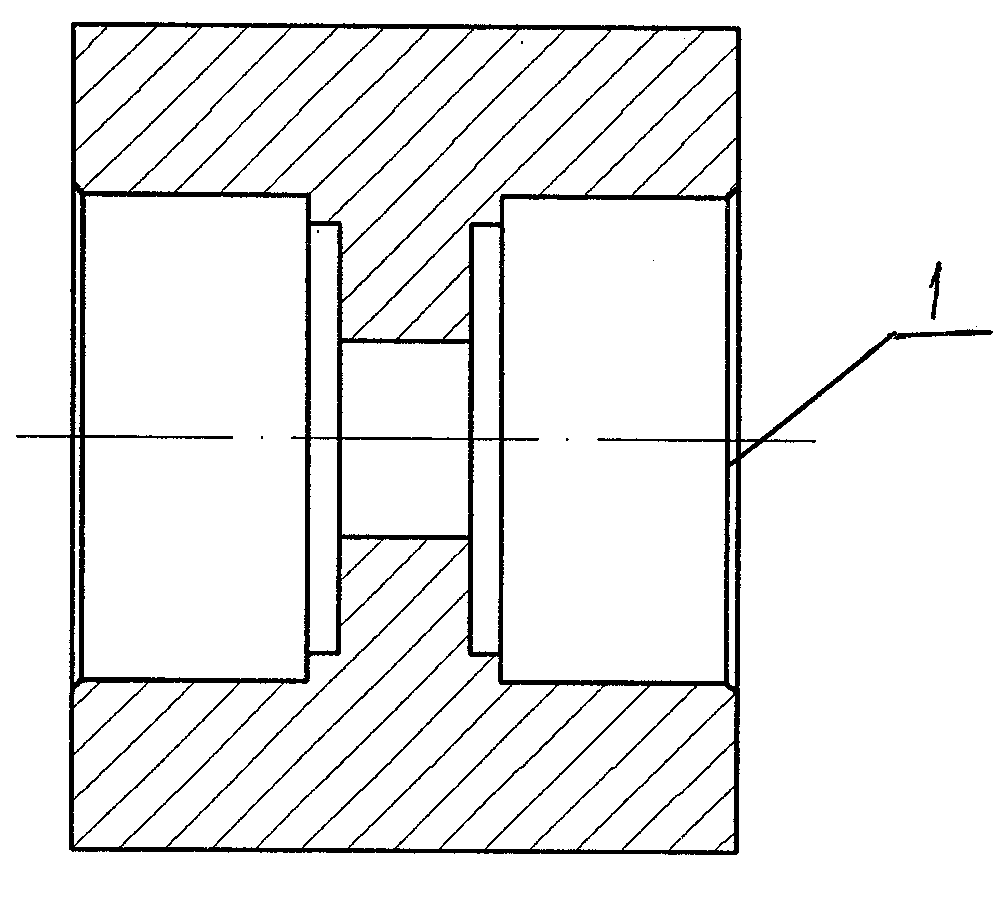

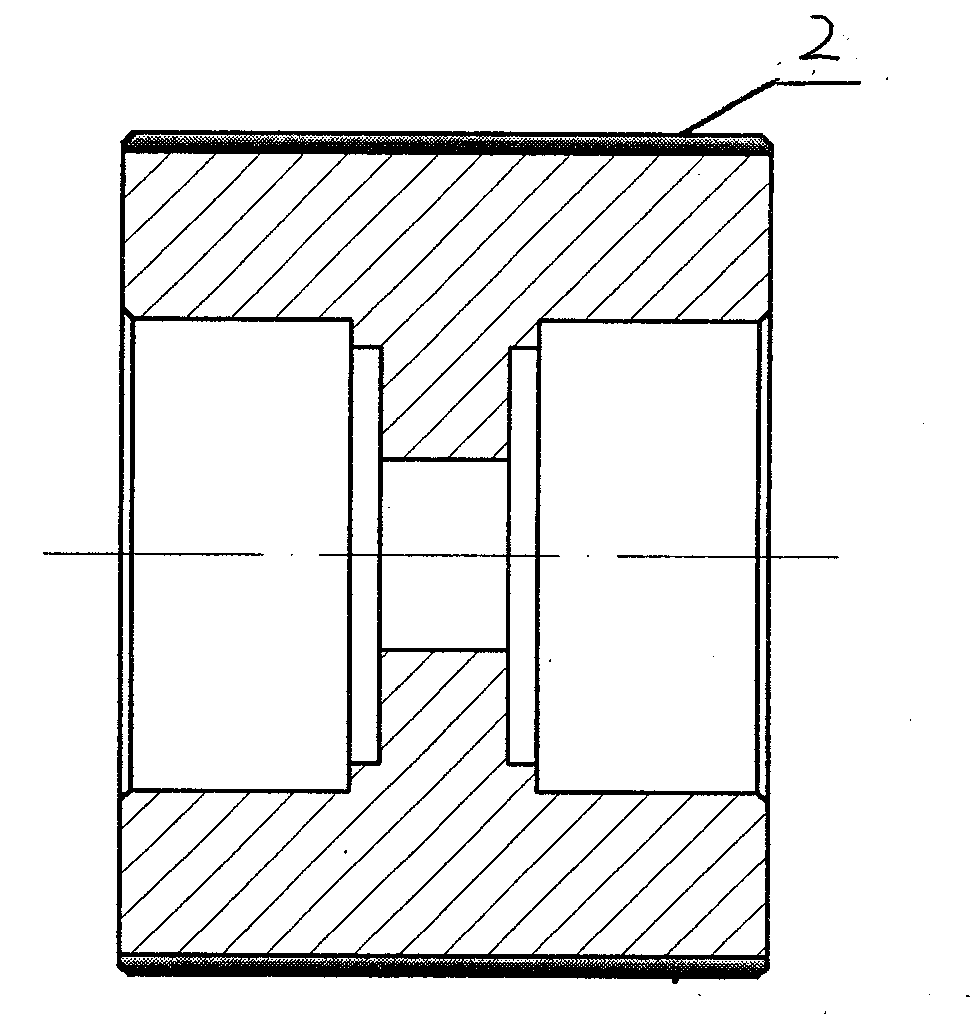

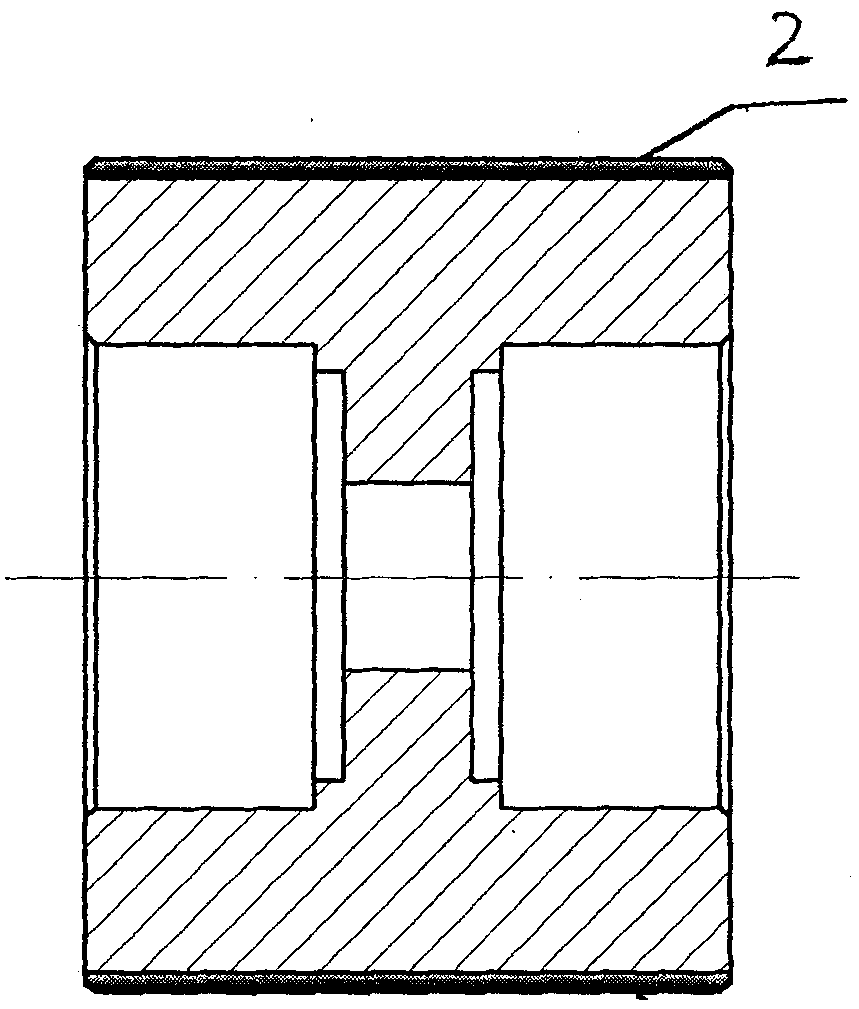

[0024] First, 40Cr steel rods are used to prepare the guide roller matrix 1, with an outer diameter of 66mm, which is 4mm smaller than the outer diameter of the finished guide roller. Other dimensions are prepared according to the finished roller, and subjected to conventional heat treatment. Ni60 powder and Cr 3 C 2 The powder is mixed by mechanical mixing method to obtain Ni60+Cr 3 C 2 alloy powder. The mixing ratio of the alloy powder is: the particle size is 200 mesh, and the Cr with good fluidity after "spheroidization" treatment 3 C 2 The powder accounts for 30% of the total mass, and the Ni60 powder with a particle size of 200 mesh accounts for 70% of the total mass. Then use acetone cleaning agent to remove oil and rust on the surface of the carrier roller matrix 1 . Preheat the guide roller matrix 1 to be clad to 280°C. The method of pneumatic powder feeding is adopted, the powder transmission speed of the powder feeder is 120g / min, and the argon gas protection...

Embodiment 2

[0026] Firstly, 40Cr steel bar is used to prepare the guide roller matrix 1, the outer diameter is 86mm, and the outer diameter is 4mm smaller than the outer diameter of the finished guide roller, and the other dimensions are prepared according to the finished roller, and the conventional heat treatment is carried out by mechanical mixing method. Get Ni60+Cr 3 C 2 Alloy powder, the mixing ratio of the alloy powder is: the particle size is 200 mesh, and the Cr with good fluidity after "spheroidization" treatment 3 C 2 The powder accounts for 40% of the total mass, and the Ni60 powder with a particle size of 200 mesh accounts for 60% of the total mass. Then remove the oil stain and rust on the surface of the 40Cr steel guide roller parent body 1 with acetone cleaning agent. Preheat the guide roller matrix 1 to be clad to 300°C; adopt the method of pneumatic powder feeding, the powder transmission speed of the powder feeder is 120g / min, and the argon gas protection. Use a 6KW...

Embodiment 3

[0028] Firstly, 40Cr steel rods are used to prepare the guide roller body, with an outer diameter of 96mm, which is 4mm smaller than the outer diameter of the finished guide roller. Other sizes are prepared according to the finished roller and subjected to conventional heat treatment. Using mechanical mixing method to obtain Ni60+Cr 3 C 2 alloy powder. The mixing ratio of the alloy powder is: the particle size is 200 mesh, and the Cr with good fluidity after "spheroidization" treatment 3 C 2 The powder accounts for 40% of the total mass, and the Ni60 powder with a particle size of 200 mesh accounts for 60% of the total mass. Then use acetone cleaning agent to remove the oil and rust on the surface of the 40Cr steel roller parent body. Preheat the parent body of the guide roller to be clad to 300°C; adopt the method of pneumatic powder feeding, the speed is 150g / min, and protect it with argon; scan through a 6KW high-power laser, the laser power is P=3200W, and the spot dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com