A kind of preparation method of Wo3 hydrate nano film

A nano-film and hydrate technology, which is applied in chemical instruments and methods, crystal growth, coating, etc., can solve the problems of complex process, long preparation cycle, and difficulty in precise control, and achieve simple process equipment, short preparation cycle, and shape The effect of appearance rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

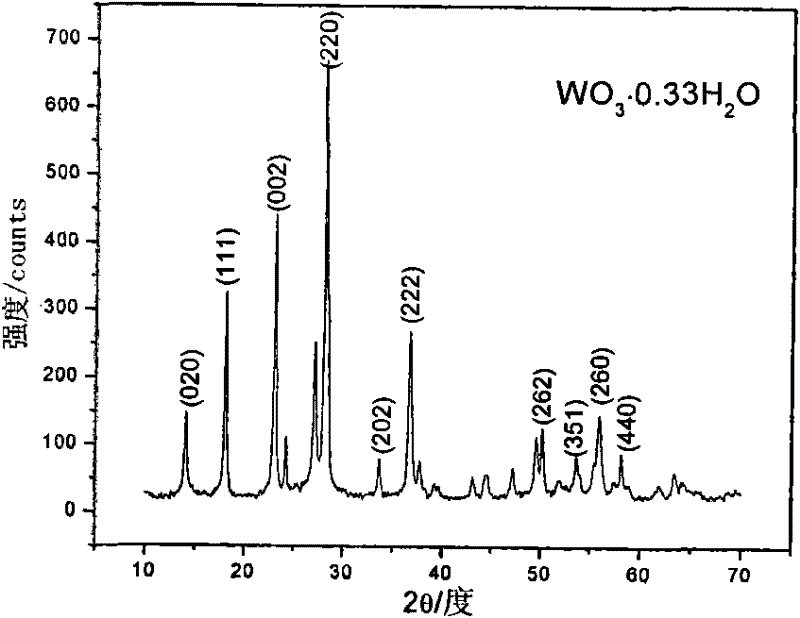

Image

Examples

Embodiment 1

[0014] Embodiment 1: 1) at first, add 20ml analytically pure hydrogen peroxide solution that volume fraction is 30% in the beaker, and beaker is placed in cold water bath, slowly, add 4g analytically pure, particle size is 200 Target tungsten powder, after the reaction is finished, collect the filtrate in the beaker and record it as solution A;

[0015] 2) Then, add deionized water to solution A so that the concentration of element W in the solution is 0.181mol / L to obtain solution B;

[0016] 3) Film substrate cleaning: the glass slide was ultrasonically oscillated in water and absolute ethanol for 10 minutes, and then mixed with 70% nitric acid and 30% hydrogen peroxide at a volume ratio of 1:1 to obtain a mixed solution , immerse the washed substrate in the mixed solution for activation treatment for 3 hours;

[0017] 4) Pour the above B solution into the microwave hydrothermal reaction kettle, the filling degree is controlled at 60%, and then put the activated substrate; ...

Embodiment 2

[0020] Embodiment 2: 1) at first, in beaker, add 20ml analytical pure hydrogen peroxide solution that the volume fraction is 30%, and beaker is placed in cold water bath, slowly, add 4g analytical pure, particle size is 200 Target tungsten powder, after the reaction is finished, collect the filtrate in the beaker and record it as solution A;

[0021] 2) Then, add deionized water to solution A so that the concentration of element W in the solution is 0.054mol / L to obtain solution B;

[0022] 3) Film substrate cleaning: ultrasonically vibrate the ITO glass plate in water and absolute ethanol for 20 minutes in turn, then mix nitric acid with a volume fraction of 70% and hydrogen peroxide with a volume fraction of 30% in a volume ratio of 1:1 to obtain a mixed solution , immerse the washed substrate in the mixed solution for activation treatment for 1.5 hours;

[0023] 4) Pour the above B solution into the microwave hydrothermal reaction kettle, control the filling degree at 40%,...

Embodiment 3

[0025] Embodiment 3: 1) at first, in beaker, add 20ml analytical pure hydrogen peroxide solution that the volume fraction is 30%, and beaker is placed in cold water bath, slowly, add 4g analytical pure, particle size is 200 Target tungsten powder, after the reaction is finished, collect the filtrate in the beaker and record it as solution A;

[0026] 2) Then, add deionized water to solution A so that the concentration of element W in the solution is 0.005mol / L to obtain solution B;

[0027] 3) Film substrate cleaning: ultrasonically vibrate the Si substrate in water and absolute ethanol for 5 minutes in sequence, then mix 70% nitric acid and 30% hydrogen peroxide at a volume ratio of 1:1 to obtain a mixture, Soak the washed substrate in the mixed solution for activation treatment for 5 hours;

[0028] 4) Pour the above B solution into the microwave hydrothermal reaction kettle, control the filling degree at 50%, and then put the activated substrate; then seal the microwave hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com