Dissolving-out process for large-sized pipeline remaining tank of diasporite bauxite ore

A bauxite and boehmite technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of increasing the processing capacity of a single equipment, difficult to clean the scarring of the heating pipe, unable to use hydraulic cleaning, etc. The effect of engineering investment and operating costs, large capacity for processing ore pulp, and long operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

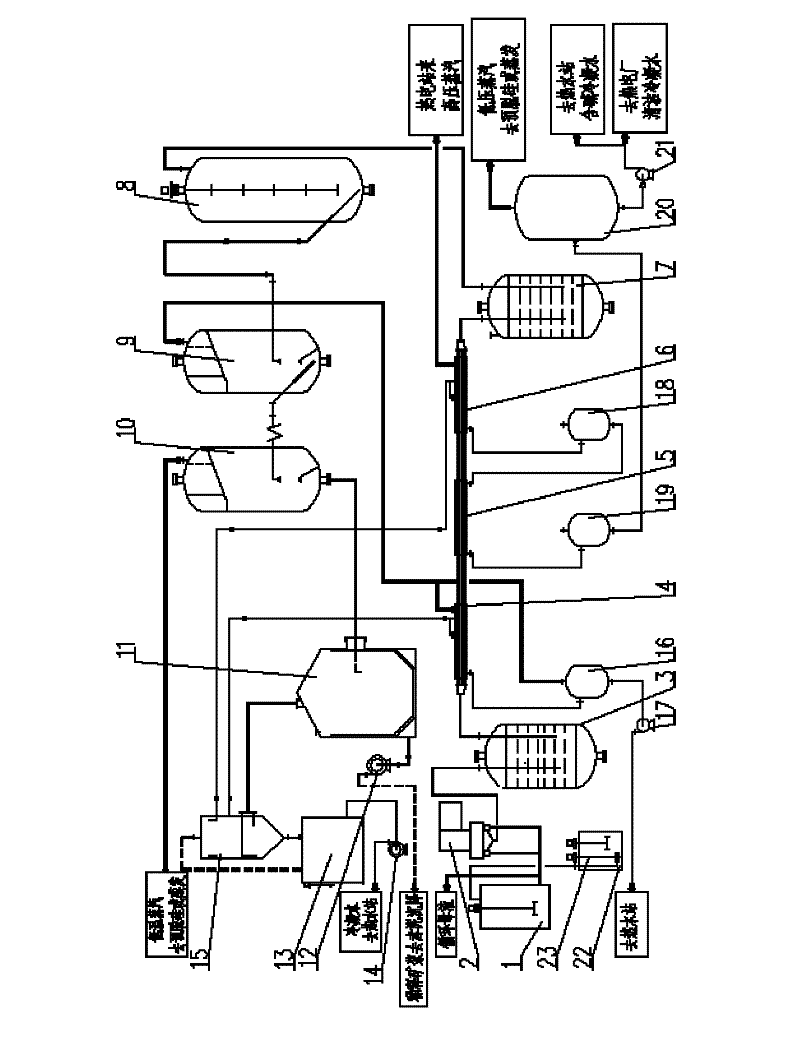

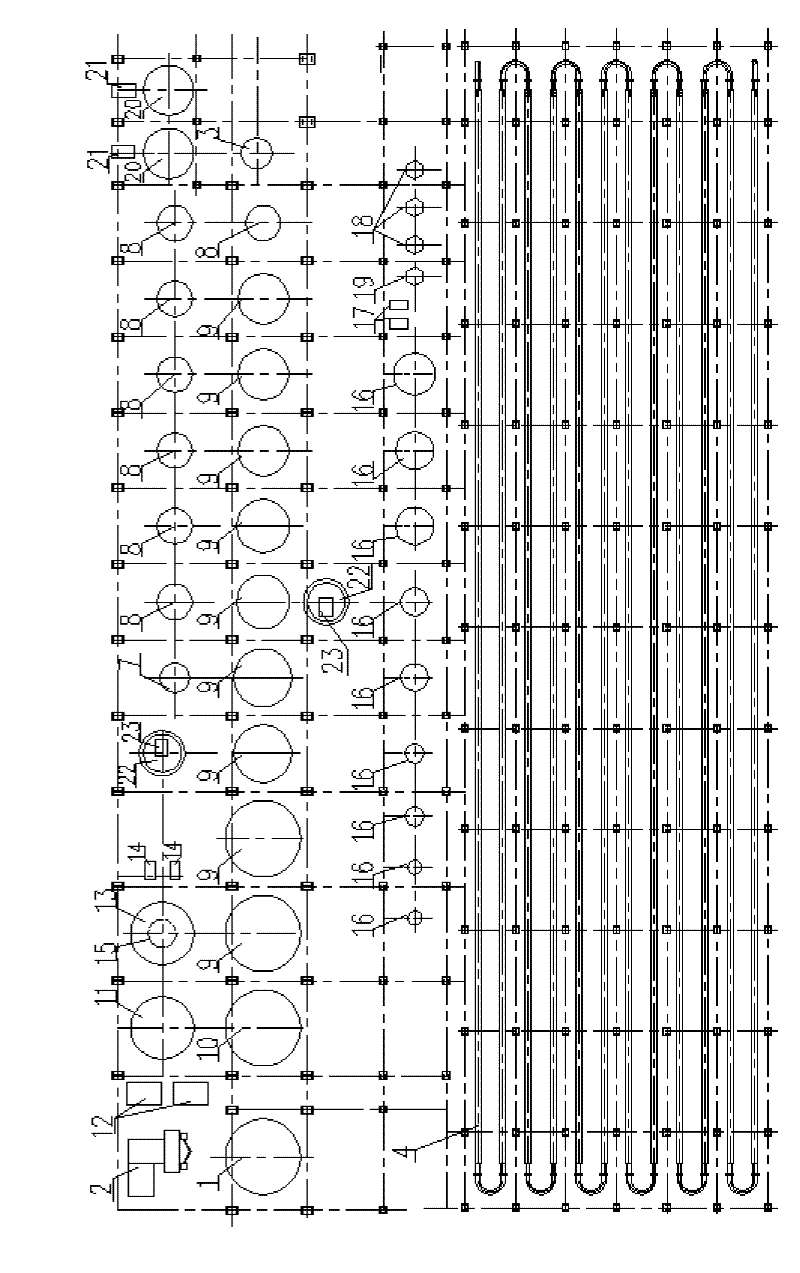

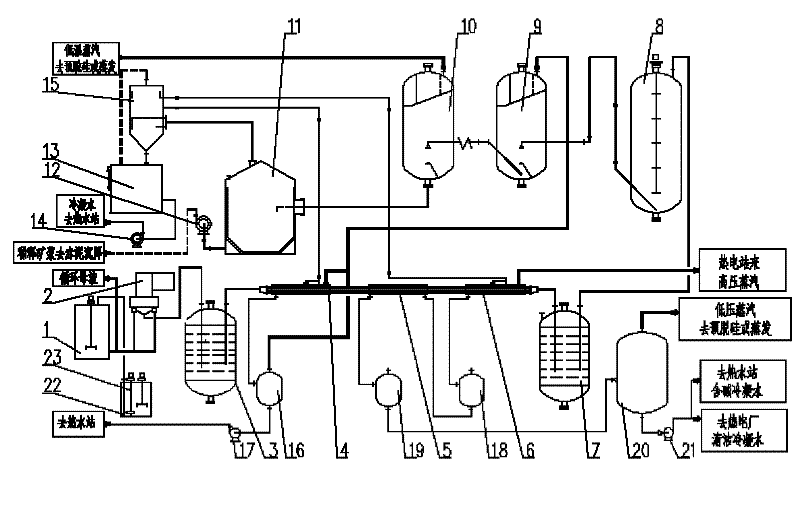

[0052] The processed raw material is gibbsite plus boehmite mixed type bauxite. The stripping process is carried out according to the following steps:

[0053] 1) Mix the pre-desiliconized desiliconized ore slurry with the circulating mother liquor at the outlet of the desiliconized discharge tank, and send the mixed slurry at 93°C to the primary pulse buffer through a diaphragm pump.

[0054] 2) After passing through the first-level pulse buffer, the slurry first enters the ninth-level secondary steam multi-inner tube casing preheater. Preheat to 205°C by secondary steam.

[0055] The inner and outer tubes of the nine-stage secondary steam multi-inner tube casing preheater receive secondary steam from the 1st to 9th flash evaporators, and the condensed water generated by heating enters the 1st to 9th secondary steam condensate tanks , all the secondary steam condensate tanks are connected in series as the pressure decreases, and the top of each secondary steam condensate ta...

Embodiment 2

[0065] The processed raw material is gibbsite plus boehmite mixed type bauxite. The stripping process is carried out according to the following steps:

[0066] 1) The pre-desiliconized desiliconized ore slurry is mixed with the circulating mother liquor at the outlet of the desiliconized discharge tank, and the mixed slurry at 95°C is sent to the first-stage pulse buffer through a diaphragm pump.

[0067] 2) After passing through the first-level pulse buffer, the slurry first enters the ninth-level secondary steam multi-inner tube casing preheater. Preheat to 210°C by secondary steam.

[0068] The inner and outer tubes of the nine-stage secondary steam multi-inner tube casing preheater receive secondary steam from the 1st to 9th flash evaporators, and the condensed water generated by heating enters the 1st to 9th secondary steam condensate tanks , all the secondary steam condensate tanks are connected in series as the pressure decreases, and the top of each secondary steam c...

Embodiment 3

[0078] The processed raw material is gibbsite plus boehmite mixed type bauxite. The stripping process is carried out according to the following steps:

[0079] 1) The pre-desiliconized desiliconized ore slurry is mixed with the circulating mother liquor at the outlet of the desiliconized discharge tank, and the mixed slurry at 90°C is sent to the first-stage pulse buffer through a diaphragm pump.

[0080] 2) After passing through the first-level pulse buffer, the slurry first enters the ninth-level secondary steam multi-inner tube casing preheater. Preheated to 200°C by secondary steam.

[0081] The inner and outer tubes of the nine-stage secondary steam multi-inner tube casing preheater receive secondary steam from the 1st to 9th flash evaporators, and the condensed water generated by heating enters the 1st to 9th secondary steam condensate tanks , all the secondary steam condensate tanks are connected in series as the pressure decreases, and the top of each secondary steam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com