Aluminum-silicon-zinc-rare earth-containing hot dip coating alloy and method for preparing same

A hot-dip plating and alloying technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of easy loss of protective effect, loss of anti-corrosion effect, and aggravated part failure, so as to solve the problem of contact corrosion , Enhanced wear resistance and liquid fluidity, and the effect of improving the performance of contact corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The hot-dip alloy is made of aluminum, silicon, zinc, rare earth elements and TiO 2 Composed of nano-oxide particle reinforcement, the percentage of each component to the total mass is: silicon content: 8-24%, zinc content: 1.2-3.1%, rare earth element content: 0.02-0.5%, TiO 2 Content: 1 to 2%, the balance is aluminum, see the following table 1 for details:

[0042] Table 1: The mass percentage content (%) and related index parameters of each component in the total weight

[0043]

Embodiment 2

[0045] The hot-dip alloy is made of aluminum, silicon, zinc, rare earth elements and CeO 2 Composed of nano-oxide particle reinforcement, the percentage of each component to the total mass is: silicon content: 8-24%, zinc content: 1.2-3.1%, rare earth element content: 0.02-0.5%, CeO 2 Content: 1 to 2%, the balance is aluminum, see the following table 2 for details:

[0046] Table 2: The mass percentage content (%) and related index parameters of each component in the total weight

[0047]

Embodiment 3

[0049] The hot-dip alloy is composed of aluminum, silicon, zinc, rare earth elements and nano-oxide particle reinforcing agent, wherein the nano-oxide particle is TiO 2 and CeO 2 , and TiO 2 and CeO 2 The ratio is 1: (1~3), and the percentages of each component to the total mass are: silicon content: 8-24%, zinc content: 1.2-3.1%, rare earth element content: 0.02-0.5%, TiO 2 and CeO 2 The total content of aluminum alloy: 1~2%, the balance is aluminum, see the following table 3 for details:

[0050] Table 3: The mass percentage content (%) and related index parameters of each component accounting for the total weight

[0051]

[0052] In embodiment 1-3, preferably, wherein each component accounts for the total mass percentage as follows: silicon content: 12-20%, zinc content: 1.5-2.5%, rare earth element content: 0.1-0.3%, nano oxide particles The total content of enhancer: 1.2~1.8%

[0053] More preferably, the silicon content is preferably 15-20%, more preferably 19%...

PUM

| Property | Measurement | Unit |

|---|---|---|

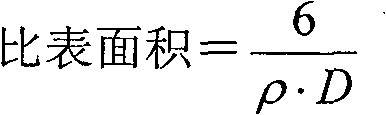

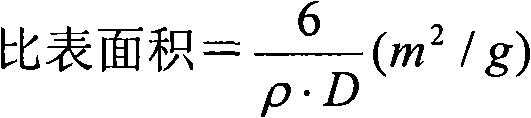

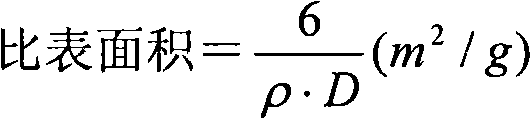

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com