Method for preparing carbon nano tube loaded cobalt-platinum alloy catalyst

An alloy catalyst, carbon nanotube technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., to achieve suitable for large-scale production, rapid reaction, and improved Pt source The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

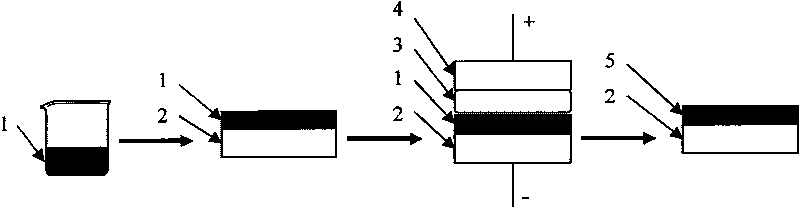

Image

Examples

Embodiment 1

[0024] 1) Surface pretreatment of carbon nanotubes:

[0025] ① Soak carbon nanotubes in 1M hydrochloric acid at room temperature for 24 hours, filter 5 times, and dry in vacuum;

[0026] ② Take 2.02 g of carbon nanotubes dried in step ① and put them in a three-necked flask, and add 180 ml of H 2 SO 4 and 60ml HNO 3 (HNO 3 The dropping speed should be slow), put it in an oil bath at 60°C, reflux for 7 hours, cool to room temperature after the reaction, filter and wash repeatedly until the pH is neutral, and dry in vacuum for 24 hours to obtain a modified product with good surface hydrophilicity carbon nanotubes;

[0027] 2) Preparation of working electrode:

[0028] ①Weigh 50mg surface modified carbon nanotubes, 0.075mmol CoCl 2 ·6H 2 O, 0.05 mmol H 2 PtCl 6 ·6H 2 O and 0.05ml mass fraction of 5% nafion solution were added to 2.2ml water for dissolving, ultrasonically dispersed for 30min to obtain carbon slurry;

[0029] ② Coat the carbon paste prepared in step ① on ...

Embodiment 2

[0033] 1) Surface pretreatment of carbon nanotubes:

[0034] ① Soak carbon nanotubes in 1M hydrochloric acid at room temperature for 24 hours, filter 5 times, and dry in vacuum;

[0035] ②Take 1 g of the dried carbon nanotubes in step ① and put them in a three-necked flask, add 90ml of H 2 SO 4 Finally, place in an oil bath at 120°C, reflux for 5 hours, cool to room temperature after the reaction, filter and wash repeatedly until the pH is neutral, and dry in vacuum for 24 hours to obtain modified carbon nanotubes with good surface hydrophilicity;

[0036] 2) Preparation of working electrode:

[0037] ①Weigh 100mg surface modified carbon nanotubes, 0.2mmol CoSO 4 ·7H 2 O, 0.2mmol of dinitrosodiammine platinum and 0.2ml of nafion solution with a mass fraction of 5% were added to 4ml of water for dissolution, ultrasonically dispersed for 40min to obtain a carbon slurry;

[0038] ② Coat the carbon paste prepared in step ① on the conductive glass according to the substrate area...

Embodiment 3

[0042] 1) Surface pretreatment of carbon nanotubes:

[0043] ① Soak carbon nanotubes in 1M hydrochloric acid at room temperature for 24 hours, filter 5 times, and dry in vacuum;

[0044] ② Take 2.02 g of carbon nanotubes dried in step ① and place them in a three-necked flask, and add 60 ml of H 2 SO 4 and 60ml HNO 3 Finally, place in an oil bath at 80°C, reflux for 12 hours, cool to room temperature after the reaction, filter and wash repeatedly until the pH is neutral, and dry in vacuum for 24 hours to obtain modified carbon nanotubes with good surface hydrophilicity;

[0045] 2) Preparation of working electrode:

[0046] ①Weigh 100mg surface modified carbon nanotubes, 0.3mmol CoSO 4 ·7H 2 O, 0.3 mmol H 2 PtCl 6 ·6H 2 O and 1ml of nafion solution with a mass fraction of 5% were added to 5ml of water for dissolution, and ultrasonically dispersed for 60min to obtain a carbon slurry;

[0047] ② Coat the carbon paste prepared in step ① on the carbon cloth according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com