Lighting apparatus

A technology for lighting devices and high-pressure discharge lamps, which is applied to projection devices, lighting devices, discharge lamps, etc., to achieve the effects of simple mechanism, suppression of uneven color, and suppression of uneven distribution of illuminance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

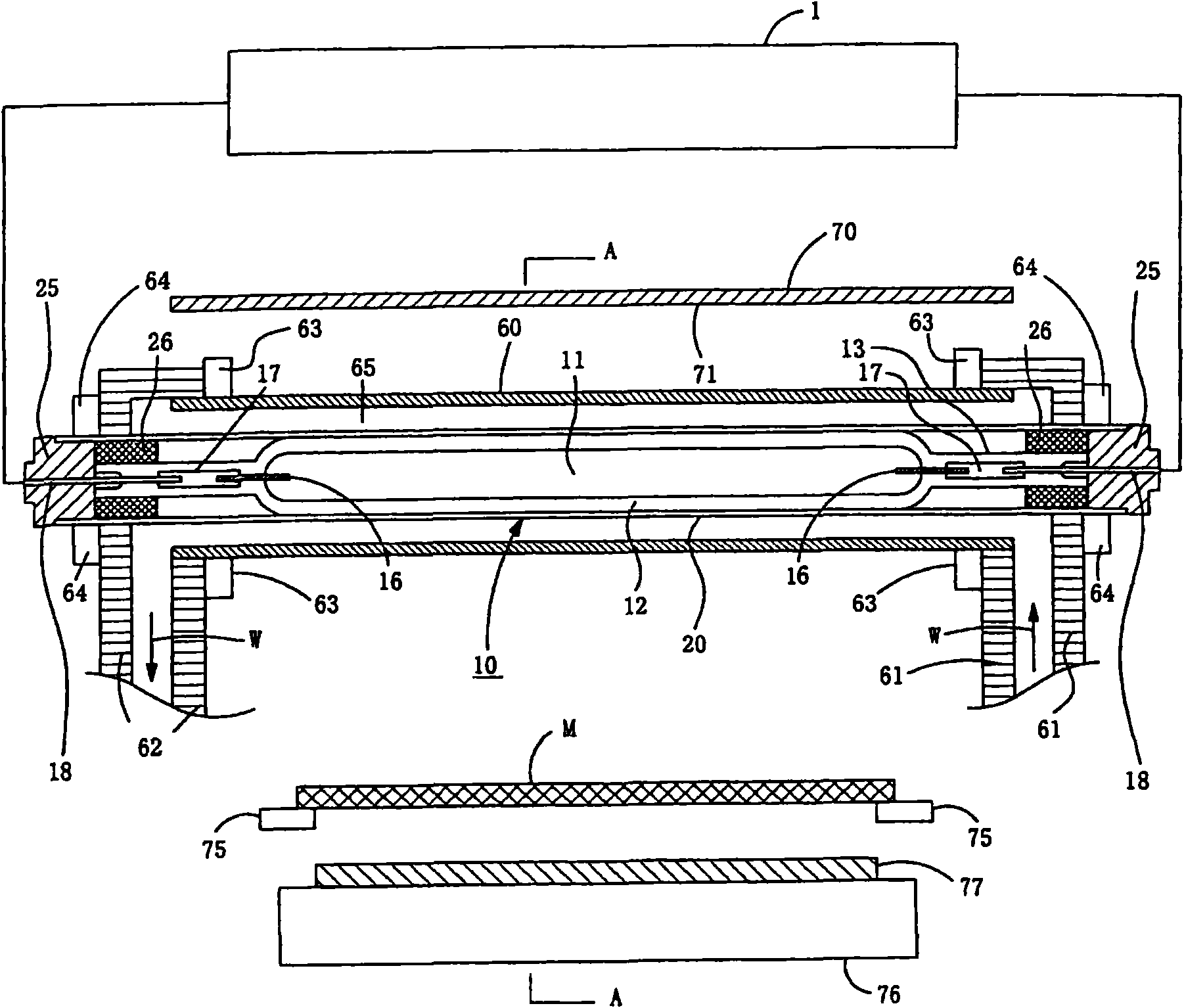

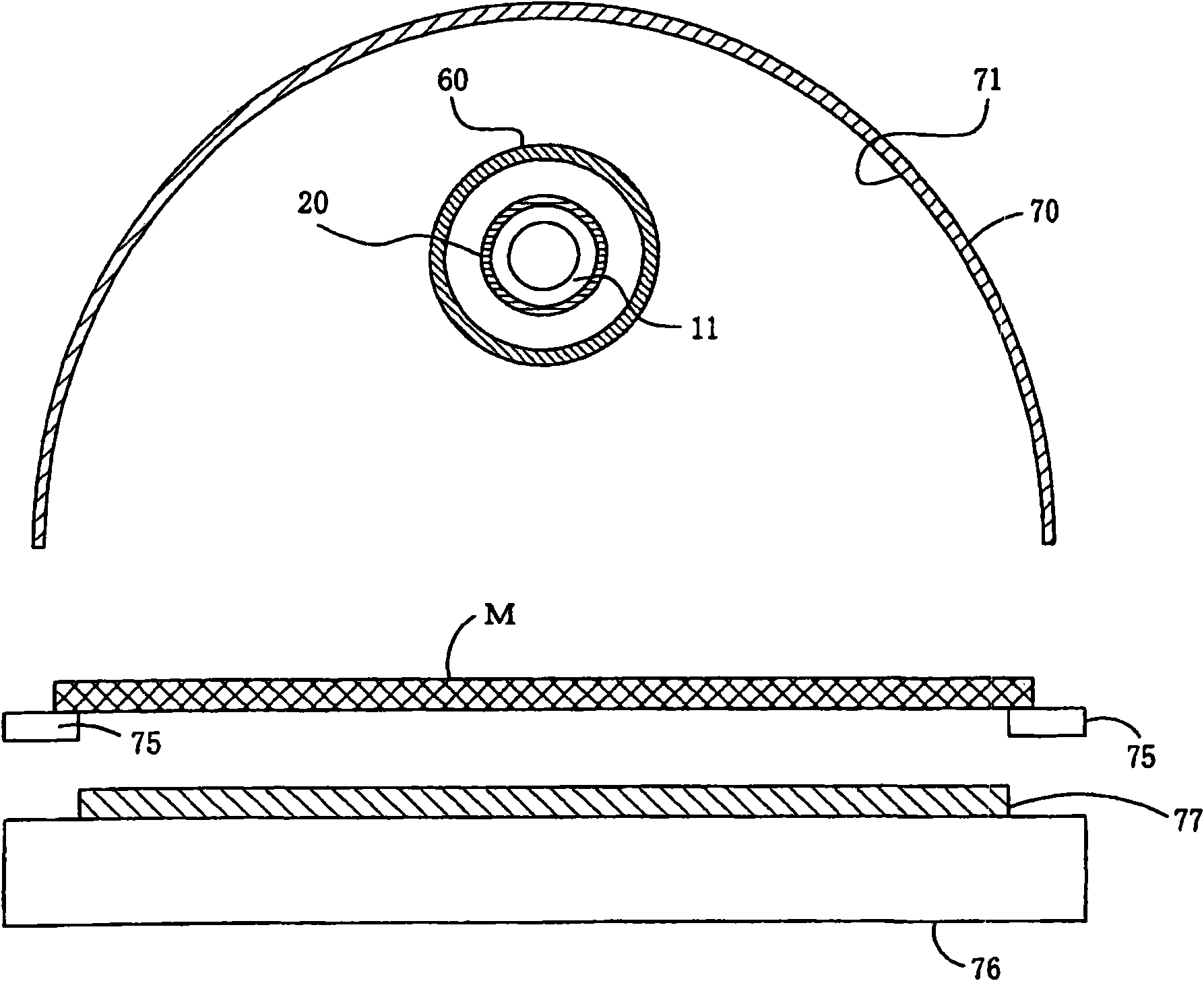

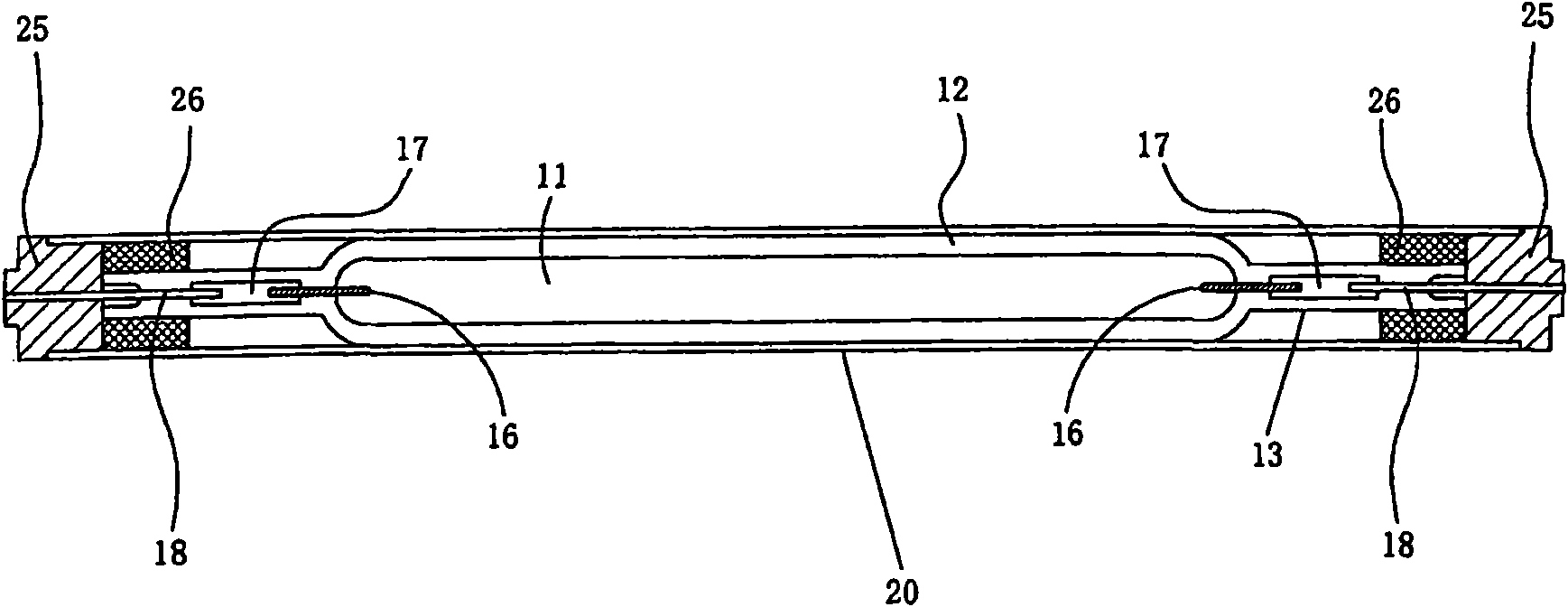

[0142] The configuration of the light irradiation device used in the experiment is shown in Figure 9 (a), having and expressing in the above figure 1 The light irradiation device has the same configuration, and its specifications are as follows.

[0143] Discharge tube (light-emitting tube): inner diameter 5.4mm outer diameter 9mm

[0144] ·Outer tube: inner diameter 9.15mm outer diameter 12mm

[0145] ·Distance between electrodes: 500mm

[0146] ·Enclosure

[0147] Mercury density 5mg / cm 3

[0148] The flow rate of cooling water flowing between the water cooling jacket and the outer pipe: 20L / min

[0149] The lighting condition of the high-pressure discharge lamp used in the experiment is to input the stable lighting frequency f1 for 1 second, and then input the frequency f1 and f2 alternately in such a way that the low frequency f2 is input into the 1-cycle component (the opening and closing of the frequency f1 is regarded as 1 cycle). signal of. That is, the stead...

experiment example 2

[0165] The experiment was carried out under the same conditions as in Experimental Example 1 above, changing the light emitting length of the lamp (distance between electrodes) to 1000 mm. Lamp specifications are described below.

[0166] Discharge tube (light-emitting tube): inner diameter 5.4mm outer diameter 9mm

[0167] ·Outer tube: inner diameter 9.15mm outer diameter 12mm

[0168] Lighting length (distance between electrodes): 1000mm

[0169] ·Enclosure

[0170] Mercury density 5mg / cm 3

[0171] The flow rate of cooling water flowing between the water cooling jacket and the outer pipe: 25L / min

[0172]The results are shown in Table 2.

[0173] In this case, the frequency f1 is between 400 Hz and 500 Hz, and it can be seen that the suppression of unevenness in illuminance by acoustic resonance is effective.

[0174] Table 2

[0175]

[0176] (Description of symbols) ◎: Large effect ○: Effective △: Some effect ×: Almost no effect

experiment example 3

[0178] The same experiment was performed under the same conditions as in Experimental Example 1 above, using a metal halide lamp with the lamp enclosure changed. Lamp specifications are described below.

[0179] Discharge tube (light-emitting tube): inner diameter 4.6mm outer diameter 10.3mm

[0180] ·Outer tube: inner diameter 10.45mm outer diameter 13mm

[0181] Lighting length (distance between electrodes): 500mm

[0182] ·Enclosure

[0183] Mercury density 2.5mg / cm 3

[0184] Iron iodide: 0.45mg / cm 3

[0185] Passive iodide: 0.06mg / cm 3

[0186] - Flow rate of cooling water flowing between the water cooling jacket and the outer tube: 20 L / min. The results are shown in Table 3.

[0187] table 3

[0188]

[0189] (Description of symbols) ◎: Large effect ○: Effective △: Some effect ×: Almost no effect

[0190] In this case, the frequency f1 is between 1000 Hz and 1200 Hz, and it can be seen that the suppression of unevenness in illuminance by acou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com