Preparation method of split type window CMP polishing pad and CMP polishing pad

A polishing pad and split-type technology, applied in the field of polishing pads, can solve problems such as high scrap rate, uneven temperature, fluctuation of tensile strength of substrate, etc., and achieve the effect of reducing scrap rate and fluctuation of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a split window CMP polishing pad, comprising the following steps:

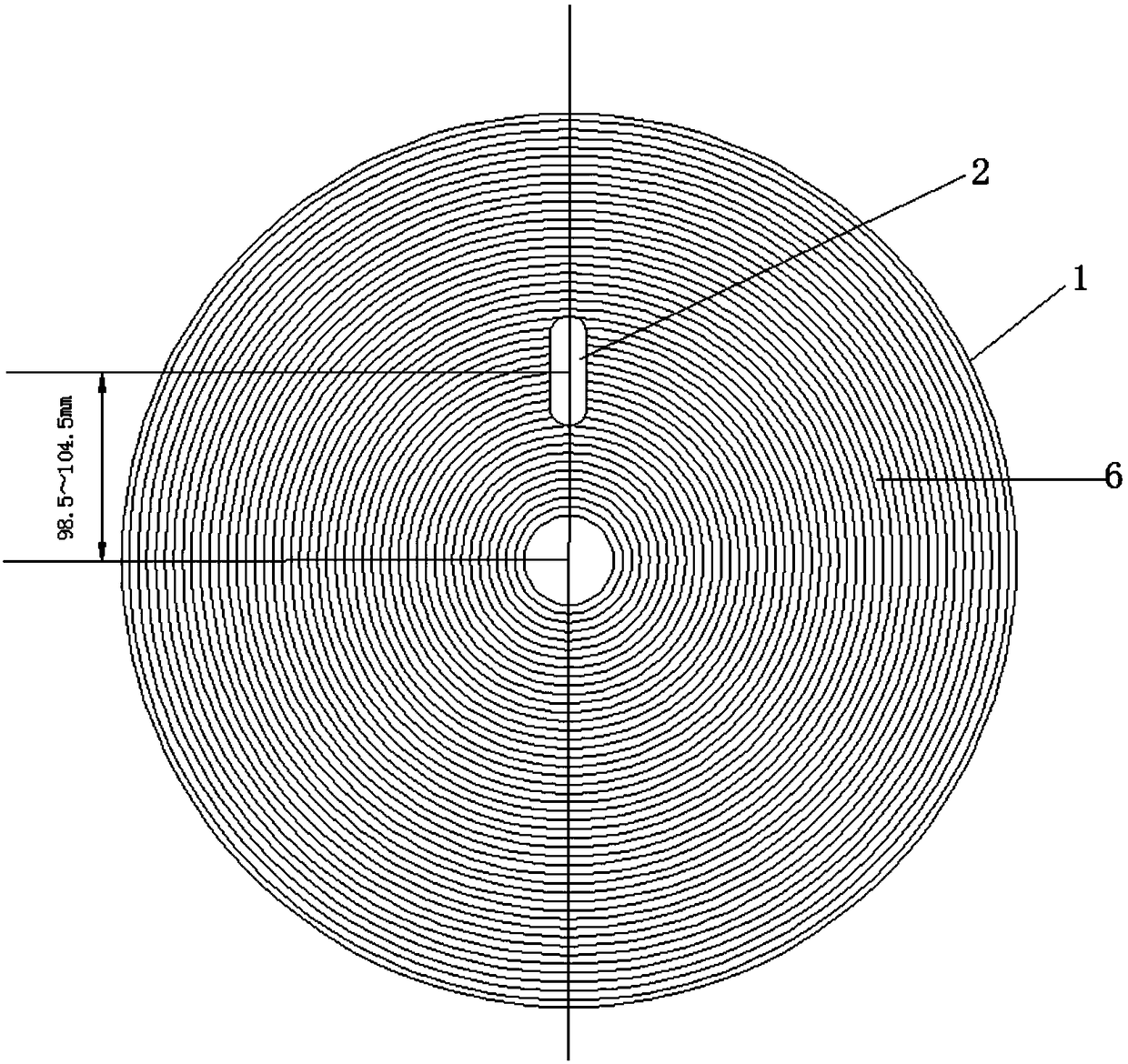

[0038] (1) Take the base material 1 and carve the groove 6 on the base material 1;

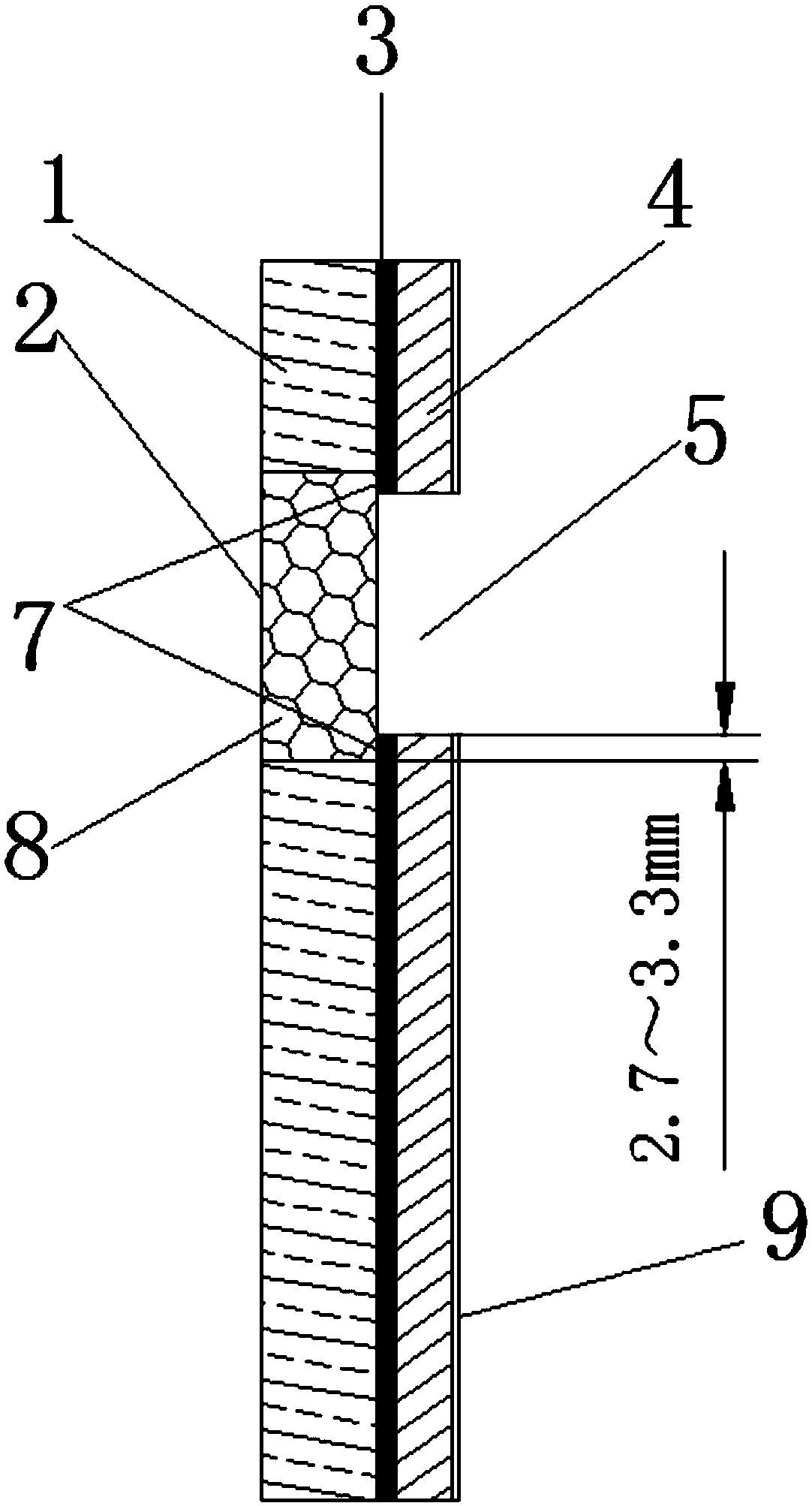

[0039] (2) Take the substrate 4 and stick a layer of back glue B 9 on the bottom of the substrate 4;

[0040] (3) engraving a window hole 2 for placing the window material 8 on the substrate 1 of the engraving groove 6;

[0041] (4) Bond the substrate 1 engraved with the window hole 2 and the substrate 4 with the back glue B 9 through the back glue A3, and then use the substrate stamping die to place the substrate 4 at the window hole 2 position of the substrate 1 A substrate hole 5 is punched out, and two window support blocks 7 are formed on both sides of the bottom of the window hole 2;

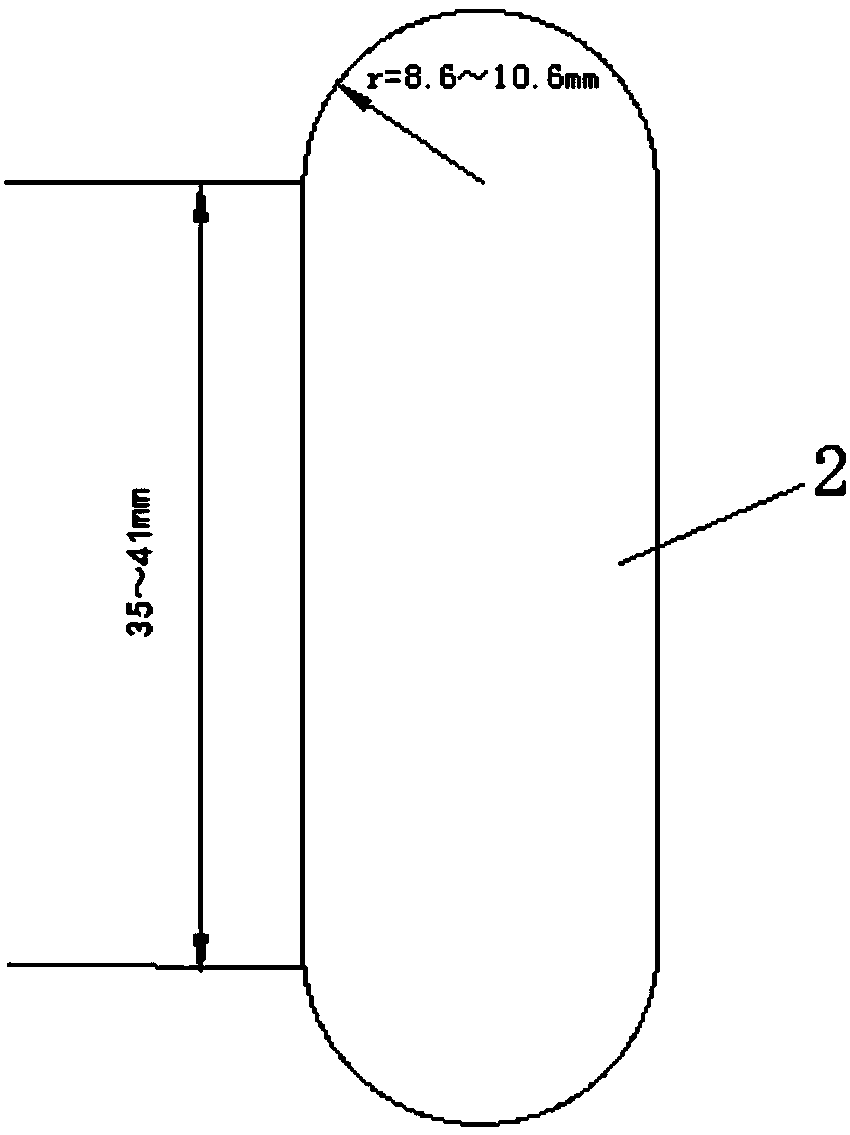

[0042] (5) Another window material is taken and the window material is stamped with a punching machine and a window material stamping die to obtain a formed window material 8;

[0043] (6) smear one deck pr...

Embodiment 2

[0054] A method for preparing a split window CMP polishing pad, comprising the following steps:

[0055] (1) Take the base material 1 and carve the groove 6 on the base material 1;

[0056] (2) Take the substrate 4 and stick a layer of back glue B 9 on the bottom of the substrate 4;

[0057] (3) engraving a window hole 2 for placing the window material 8 on the substrate 1 of the engraving groove 6;

[0058](4) Bond the base material 1 engraved with the window hole 2 and the substrate 4 with the back glue B 9 pasted through the back glue A 3, and then use the substrate stamping die to place the substrate at the position of the window hole 2 of the base material 1. 4 punch out a substrate hole 5, and form two window support blocks 7 on both sides of the bottom of the window hole 2;

[0059] (5) Another window material is taken and the window material is stamped with a punching machine and a window material stamping die to obtain a formed window material 8;

[0060] (6) smear...

Embodiment 3

[0071] A method for preparing a split window CMP polishing pad, comprising the following steps:

[0072] (1) Take the base material 1 and carve the groove 6 on the base material 1;

[0073] (2) Take the substrate 4 and stick a layer of back glue B 9 on the bottom of the substrate 4;

[0074] (3) engraving a window hole 2 for placing the window material 8 on the substrate 1 of the engraving groove 6;

[0075] (4) Bond the base material 1 engraved with the window hole 2 and the substrate 4 with the back glue B 9 pasted through the back glue A 3, and then use the substrate stamping die to place the substrate at the position of the window hole 2 of the base material 1. 4 punch out a substrate hole 5, and form two window support blocks 7 on both sides of the bottom of the window hole 2;

[0076] (5) Another window material is taken and the window material is stamped with a punching machine and a window material stamping die to obtain a formed window material 8;

[0077] (6) smea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com