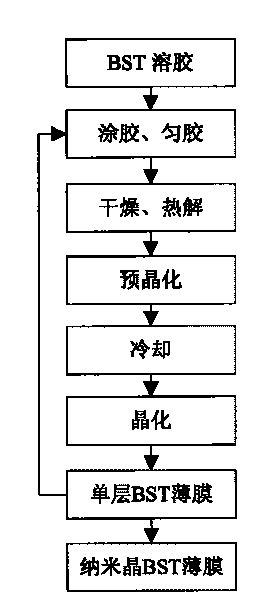

Method for preparing nano-crystalline BST film

A nanocrystalline and thin film technology, applied in the field of preparation of nanocrystalline barium strontium titanate thin film, can solve the problems of expensive equipment, serious film cracks, poor compactness, etc., achieve stable frequency characteristics and temperature characteristics, and improve comprehensive dielectric tuning performance , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

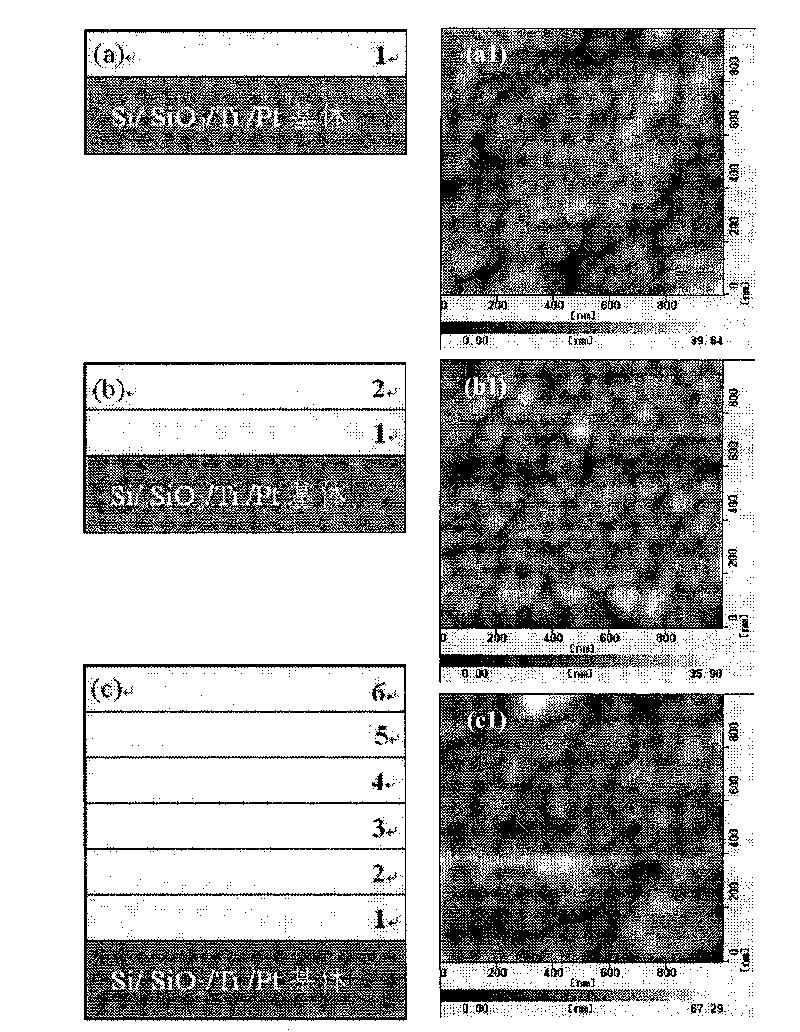

[0042] Example 2: Si / SiO 2 / Ti / Pt substrate to prepare layer-by-layer precrystallized BST thin film, the preparation steps are as follows:

[0043] Step 1: Prepare BST sol, which specifically includes the following steps:

[0044] Step 1-1: Dissolving inorganic barium salt and inorganic strontium salt soluble in glacial acetic acid with a molar ratio of Ba:Sr=x:(1-x) in glacial acetic acid, stirring at 60-80°C for 60 ~120 minutes to form a barium strontium precursor where x = 0.6.

[0045] Step 1-2: Mix butyl titanate and acetylacetone with a molar ratio of 1:2, heat and stir for 60-120 minutes to form a titanium precursor solution.

[0046] Step 1-3: Mix the barium-strontium precursor solution obtained in step 1-1 with the titanium precursor solution obtained in step 1-2, wherein the sum of the molar amounts of Ba and Sr in the barium-strontium precursor solution is equal to the molar amount of Ti in the titanium precursor solution ratio of 1:1 to 1.2; then dropwise add po...

Embodiment 4

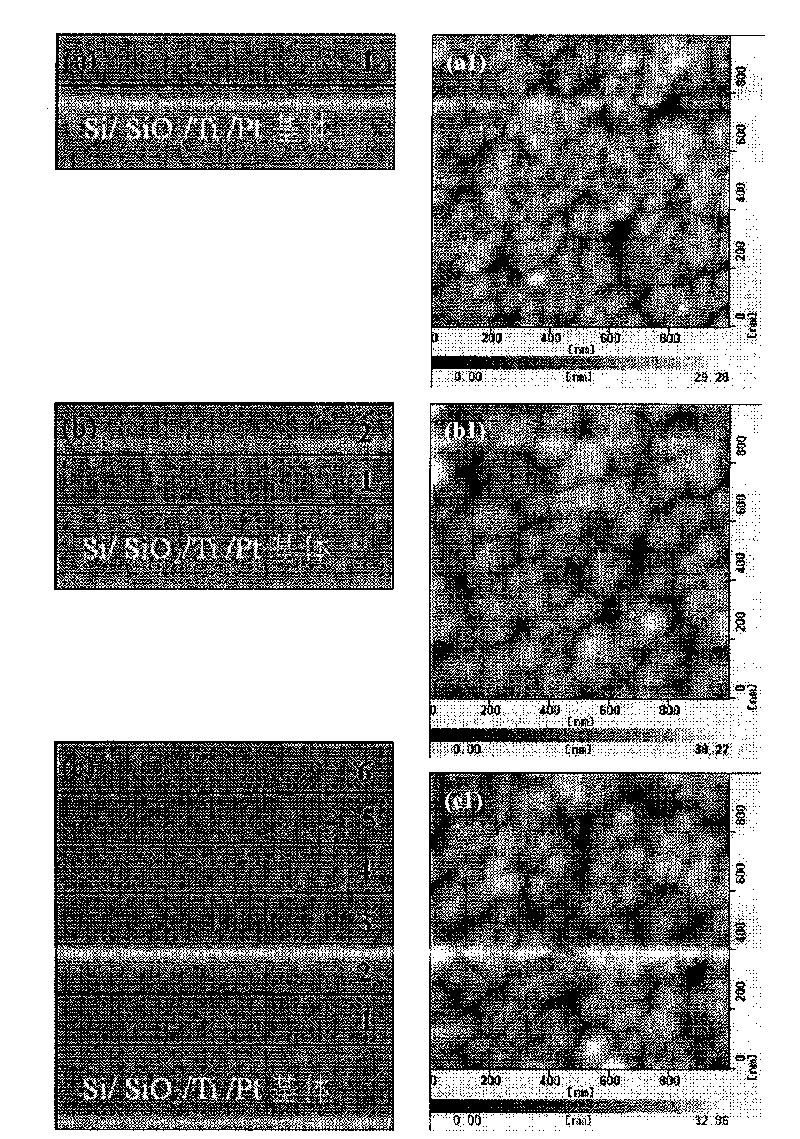

[0055] Example 4: Si / SiO 2 Layer-by-layer pre-crystallized BST films with different crystallization temperatures were prepared on the / Ti / Pt substrate, and the preparation steps were as follows:

[0056] Step 1: Prepare BST sol, which specifically includes the following steps:

[0057] Step 1-1: Dissolving inorganic barium salt and inorganic strontium salt soluble in glacial acetic acid with a molar ratio of Ba:Sr=x:(1-x) in glacial acetic acid, stirring at 60-80°C for 60 ~120 minutes to form a barium strontium precursor where x = 0.6.

[0058] Step 1-2: Mix butyl titanate and acetylacetone with a molar ratio of 1:2, heat and stir for 60-120 minutes to form a titanium precursor solution.

[0059] Step 1-3: Mix the barium strontium precursor solution obtained in step 1-1 with the titanium precursor solution obtained in step 1-2, wherein the sum of the molar amounts of Ba and Sr in the barium strontium precursor solution is equal to the molar amount of Ti in the titanium precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com