Laser information coating for gold stamping

A coating and coating technology, which is applied in the field of bronzing information coating coatings, can solve the problems of unsatisfactory solvent resistance, difficulty in acrylic production, and high coating costs, and achieve low cost, high brightness, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

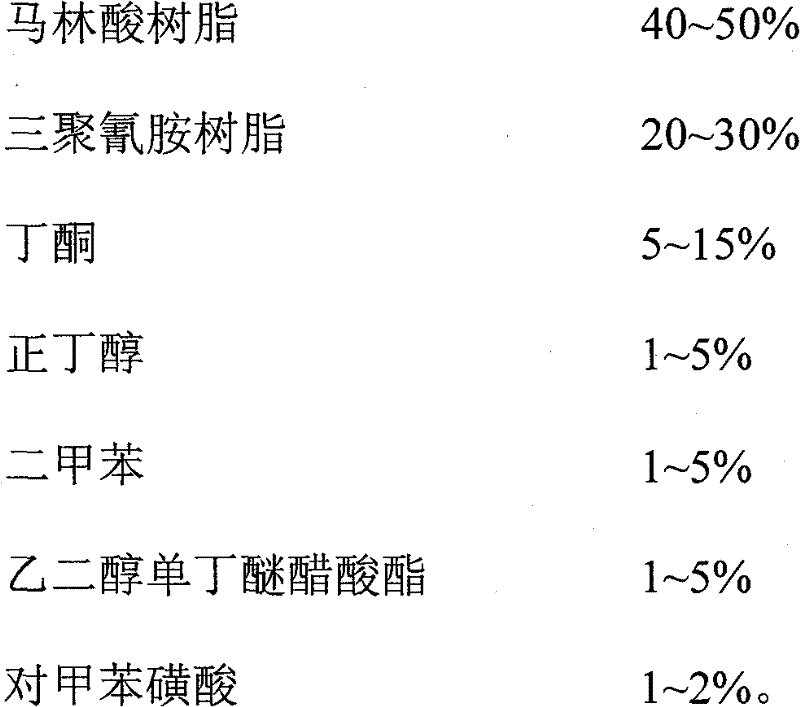

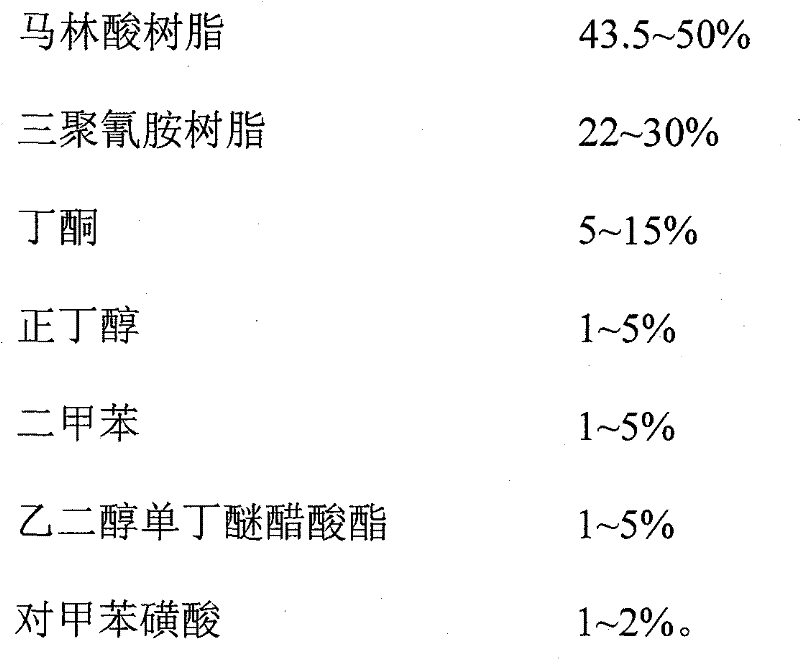

Method used

Image

Examples

Embodiment 1

[0029] The first step: first 10 parts of methyl ethyl ketone (100 parts in total of all components, each 100 grams, the same below), 5 parts of n-butanol, 4 parts of xylene and 4.5 parts of ethylene glycol monobutyl ether acetate in sequence Add it into the mixing tank, and stir evenly at a constant temperature of 26°C for 8 minutes;

[0030] Step 2: Pour 50 parts of maleic acid resin and 25 parts of melamine resin into the mixing tank in turn according to the formula ratio, and stir continuously for about 10 minutes;

[0031] Step 3: Add 1.5 parts of p-toluenesulfonic acid into the mixing tank, add it while stirring, and continue stirring for about 12 minutes after adding, you can get bronzing Liquid paint for radiating information coatings.

[0032] In order to verify the effect of the present invention, the hot stamping prepared by the above method The liquid paint of the radiation information coating, after being coated on the PET electroplated aluminum film, the tempe...

Embodiment 2

[0034] The first step: first 10 parts of methyl ethyl ketone (100 parts in total of all components, each 100 grams, the same below), 5 parts of n-butanol, 4.8 parts of xylene and 4.05 parts of ethylene glycol monobutyl ether acetate Add it into the mixing tank, and stir evenly at a constant temperature of 28°C for 10 minutes;

[0035] Step 2: Pour 45 parts of maleic acid resin and 30 parts of melamine resin into the mixing tank in sequence according to the formula ratio, and fully and continuously stir for about 10 minutes;

[0036] Step 3: Add 1.15 parts of p-toluenesulfonic acid into the mixing bucket, add while stirring, and continue stirring for about 15 minutes after adding, you can get bronzing Liquid paint for radiating information coatings.

[0037] In order to verify the effect of the present invention, the hot stamping prepared by the above method The liquid paint of the radiation information coating, after being coated on the PET electroplated aluminum film, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com