Production technology of beta-hydroxyalkylamide

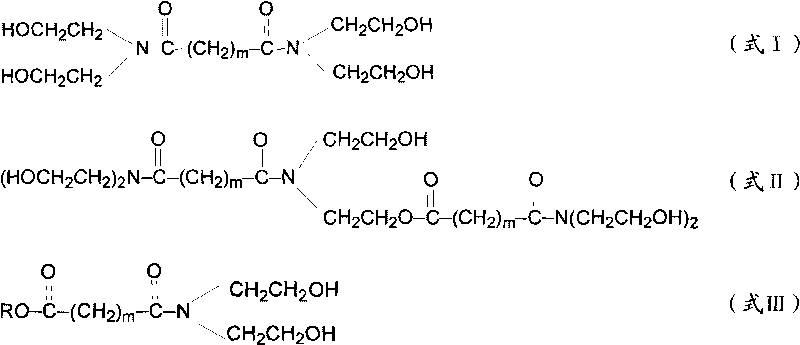

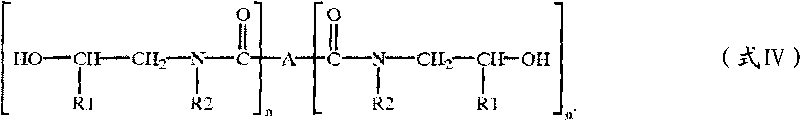

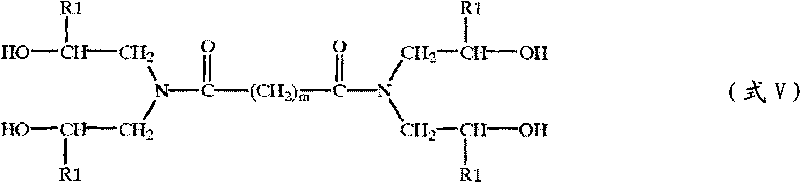

A technology of hydroxyalkylamide and production process, applied in the field of production technology of β-hydroxyalkylamide, can solve the problems of ineffective slurry sedimentation and low melting point, and achieves improved application performance, high purity, and reduced side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put 150.7kg (1.2kmol) of diethanolamine and 1.74kg of sodium methoxide into a reaction kettle with a gas dispersion device at the bottom, and heat it to 110°C under the protection of nitrogen. After the gas in the kettle is pumped out until the pressure in the kettle reaches 0.03MPa, at 1.5 Add 174.0kg (1kmol) dimethyl adipate dropwise within 2h, stir the reaction constantly, and simultaneously steam the methanol released during the reaction. After 1h of reaction, add 2.0kg of acetic acid to the reaction mixture, stir and mix thoroughly Afterwards, the temperature of the reaction system was raised to 180°C and kept warm, and the reaction system was filled with nitrogen gas bubbling through the gas dispersion device at the bottom of the reactor at a pressure of 0.5 MPa for 5 minutes and stirred continuously, and then the nitrogen flow was stopped. Evaporate excess diethanolamine under reduced pressure until the pressure of the kettle reaches 0.003MPa and continue vacuumin...

Embodiment 2

[0044] Put 266.2kg (2kmol) of diisopropanolamine and 3.0kg of potassium hydroxide mixture into a reaction kettle with a gas dispersion device at the bottom, and heat to 100°C under nitrogen protection. After the gas in the kettle was pumped out until the pressure inside the kettle reached 0.05MPa, 174.0kg (1kmol) dimethyl adipate was added dropwise within 2 hours, the reaction was continuously stirred, and the methanol released during the reaction was distilled synchronously. After another 1 hour of reaction, add 5.0kg of propionic acid to the reaction mixture, stir and mix thoroughly, then raise the temperature of the reaction system to 150°C, and pass through the gas dispersion device at the bottom of the reaction kettle at a pressure of 0.3MPa for 5 minutes. Bubble nitrogen into the molten reaction system and keep stirring, then stop nitrogen, distill off excess diisopropanolamine under reduced pressure until the pressure of the kettle reaches 0.004MPa and continue vacuuming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com