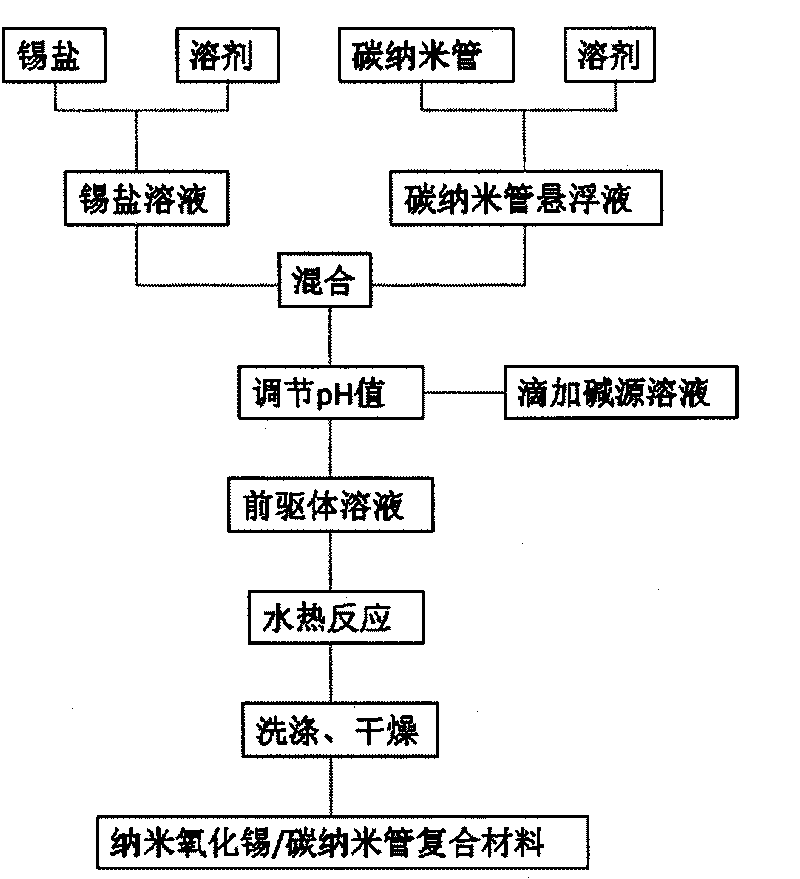

In-situ synthesis method for nano tin dioxide/carbon nano tube composite material

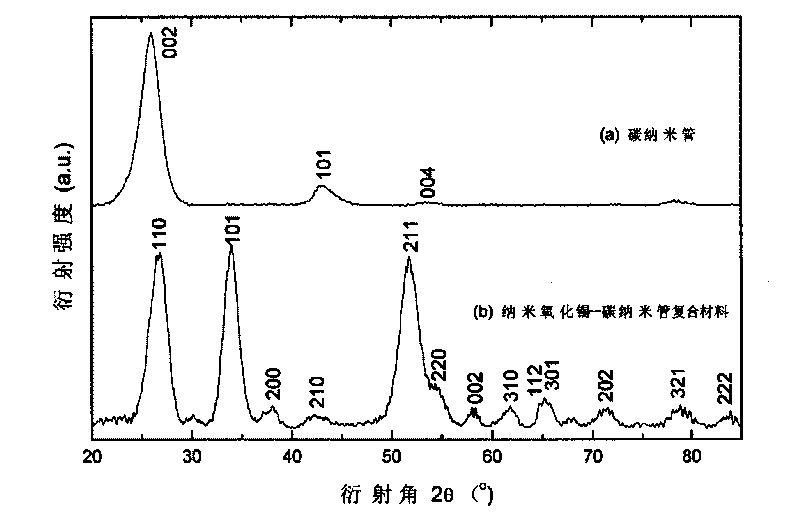

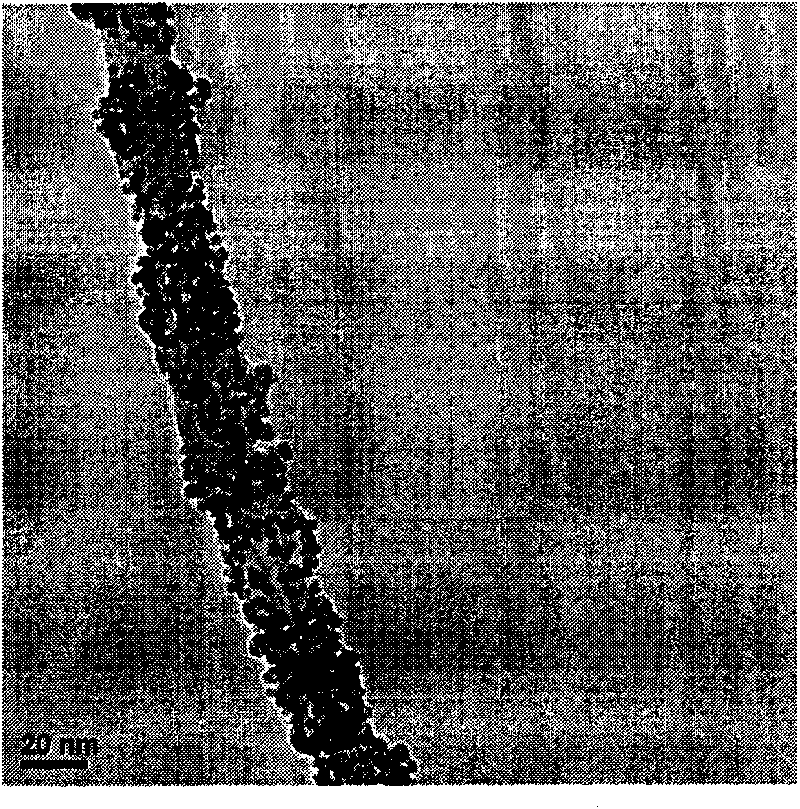

A technology of nano-tin oxide and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of large nano-SnO2 particle size, weak carbon nanotube binding, harsh preparation conditions, etc., and achieve short preparation cycle , good crystallization and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0033] Step 1, reflux the multi-walled carbon nanotubes with concentrated nitric acid at 120°C for 5 hours, then wash with deionized water several times until the pH of the washing solution = 7, and then dry at 60°C to obtain surface-functionalized multi-walled carbon nanotubes Tube;

[0034] Step 2, 1.354g of SnCl 2 .2H 2 O was dissolved in 20ml of absolute ethanol and stirred to form Sn 2+ Concentration is the stannous chloride solution of 0.3mol / L; According to the mass ratio (1:100) of carbon nanotubes and tin salt, the carbon nanotubes that acidification process is added in 20ml dehydrated alcohol ultrasonic dispersion 20min, form carbon suspension of nanotubes;

[0035] Step 3, while stirring, add the suspension of carbon nanotubes prepared in step 2 to the SnCl 2 solution, then continue to stir for 20 minutes, and then ultrasonic 10 minutes to form a mixed solution;

[0036] Step 4, while stirring, add an aqueous solution of NaOH with a concentration of 0.4 mol / L d...

specific Embodiment 2

[0040] Step 1, the multi-walled carbon nanotubes are treated with a mixed acid of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1:3 at 120° C. for 5 hours, and then washed with deionized water for several times until the washing liquid is neutral, and then heated at 60 ℃ drying to obtain surface functionalized multi-walled carbon nanotubes.

[0041] Step 2, 1.354g of SnCl 2 2H 2 O was dissolved in 20ml of absolute ethanol and stirred to form Sn 2+ Concentration is the stannous chloride solution of 0.3mol / L; According to the weight ratio (1:100) of carbon nanotubes and tin salt, the carbon nanotubes that acidification process is added in 20ml dehydrated alcohol ultrasonic dispersion 20min, form carbon suspension of nanotubes;

[0042] Step 3, while stirring, add the suspension of carbon nanotubes prepared in step 2 to the SnCl 2 solution, then continue to stir for 20 minutes, and then ultrasonic 10 minutes to form a mixed solution;

[0043]...

specific Embodiment 3

[0047] Step 1, reflux the multi-walled carbon nanotubes with concentrated nitric acid at 120°C for 5 hours, then wash with deionized water several times until the pH of the washing solution is 7, and then dry at 60°C to obtain surface-functionalized multi-walled carbon nanotube.

[0048] Step 2, 1.354g of SnCl 2 2H 2 O was dissolved in 20ml of absolute ethanol and stirred to form Sn 2+ Concentration is the tin protochloride solution of 0.3mol / L; According to the weight ratio (5:100) of carbon nanotubes and tin salt, the carbon nanotubes that acidification process is added in 20ml dehydrated alcohol ultrasonic dispersion 20min, form carbon suspension of nanotubes;

[0049] Step 3, while stirring, add the suspension of carbon nanotubes prepared in step 2 to the SnCl 2 solution, then continue to stir for 20 minutes, and then ultrasonic 10 minutes to form a mixed solution;

[0050] Step 4, while stirring, add ammonia water with a mass concentration of 7% dropwise to the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com