Solar-grade polysilicon purifying device and solar-grade polysilicon purifying method

A technology of solar energy level and purification method, which is applied to the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of the by-product slag phase that cannot be reused, the amount of slag is large, and waste the environment, etc., and achieve considerable market prospects , low cost and short investment period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

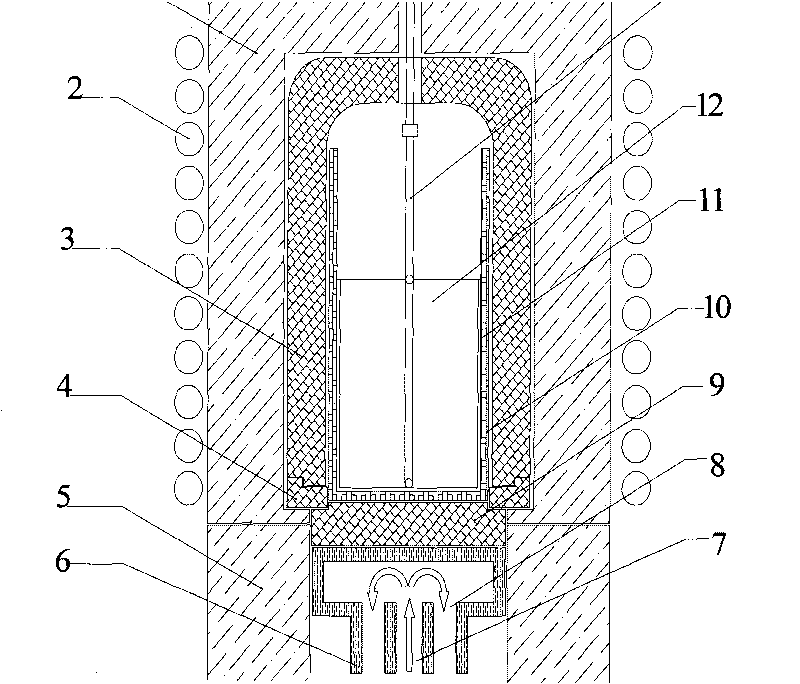

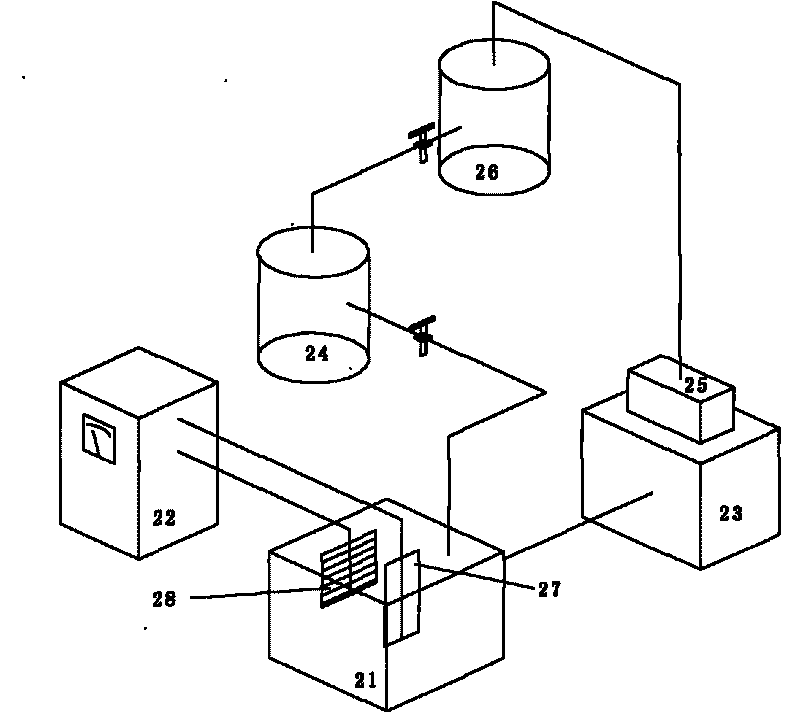

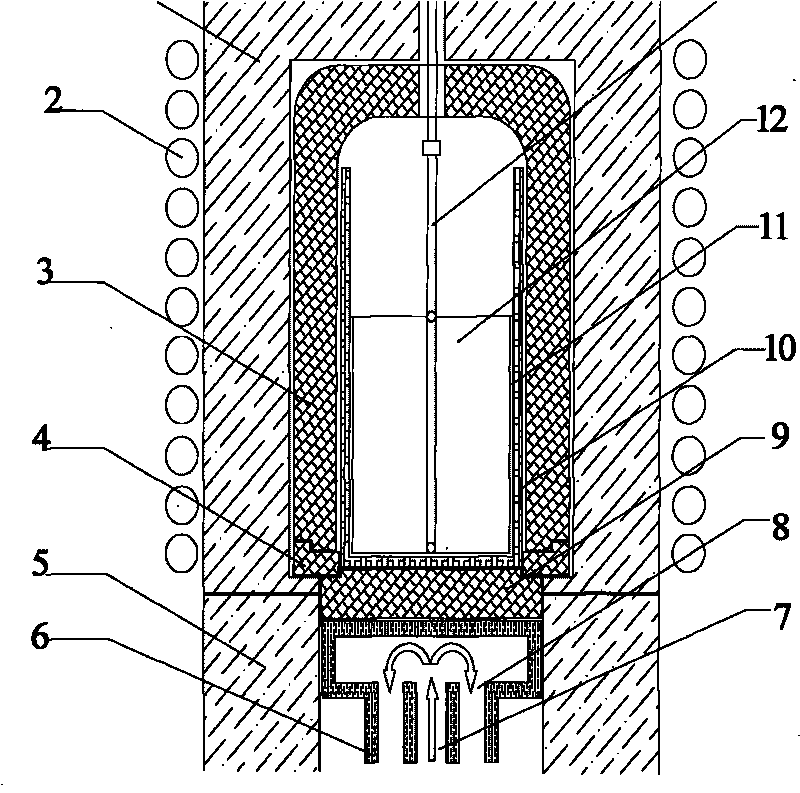

[0046] Put 216Kg of industrial silicon and 24Kg of copper into the quartz crucible, turn on the heating power supply, energize the induction heating coil, the power is 200kW, the graphite heating sleeve will generate heat by induction, and heat the silicon and copper in the quartz crucible , the copper in the crucible first melts at 1084°C, and the silicon also begins to melt slowly as the temperature rises. When the silicon in the quartz crucible is completely melted to form a silicon-copper alloy melt, a thermocouple temperature measuring device is used to measure the temperature of each point in the vertical direction inside the quartz crucible, and the induction heating power controller is adjusted to make the alloy melt in the quartz crucible Maintain a stable temperature gradient with an upper limit of 1600°C and a lower limit of 1414°C. Start the directional lifting device to drive the quartz crucible containing the alloy melt and the graphite chassis to pull down toget...

Embodiment 2

[0048] Technological process is with embodiment 1. Put 168kg of industrial silicon and 72kg of copper into a quartz crucible, turn on the heating power supply, and energize the induction heating coil with a power of 120kW. After all the silicon and copper in the crucible are melted, adjust the induction heating power controller to make the quartz crucible The alloy melt maintains a stable temperature gradient with an upper temperature limit of 1450 °C and a lower temperature limit of 1300 °C. Start the directional lifting device, and the descending speed is 30mm / h. After the orientation process is completed, the alloy silicon ingot is taken out, and the upper 50% is cut off. The remaining part is determined to be a polycrystalline silicon ingot with a purity of 99.99992%, and the crystal grain of the silicon ingot is larger than 0.5mm and is a vertically oriented columnar crystal with a resistivity of 0.5-1Ω·cm. It can be sliced directly for making solar cells. Put the cut...

Embodiment 3

[0050] Technological process is with embodiment 1. Put 192kg of industrial silicon and 48kg of copper into a quartz crucible, turn on the heating power supply, and energize the induction heating coil with a power of 150kW. After all the silicon and copper in the crucible are melted, adjust the induction heating power controller to make the quartz crucible The alloy melt maintains a stable temperature gradient with an upper temperature limit of 1500 °C and a lower temperature limit of 1350 °C. Start the directional lifting device, and the descending speed is 5mm / h. After the orientation process is completed, the alloy silicon ingot is taken out, and the upper 30% is cut off. The remaining part is determined to be a polycrystalline silicon ingot with a purity of 99.999986%, and the crystal grains of the silicon ingot are larger than 5mm and are vertically oriented columnar crystals, and the resistivity is 4.8-5Ω·cm, which can be directly sliced and used to make solar cells. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com